Tractors X60 Series. Manual - part 55

219

Maintenance

7

9

GENERAL MAINTENANCE

Brakes

Bleeding the air from the rear brake

circuit

It becomes necessary to bleed the circuit when air enters

owing to lack of oil in the relative reservoir or when the

brake system is serviced.

This operation should be carried out by specialized per-

sonnel. If, however, you decide to do it yourself, proceed

in the following way.

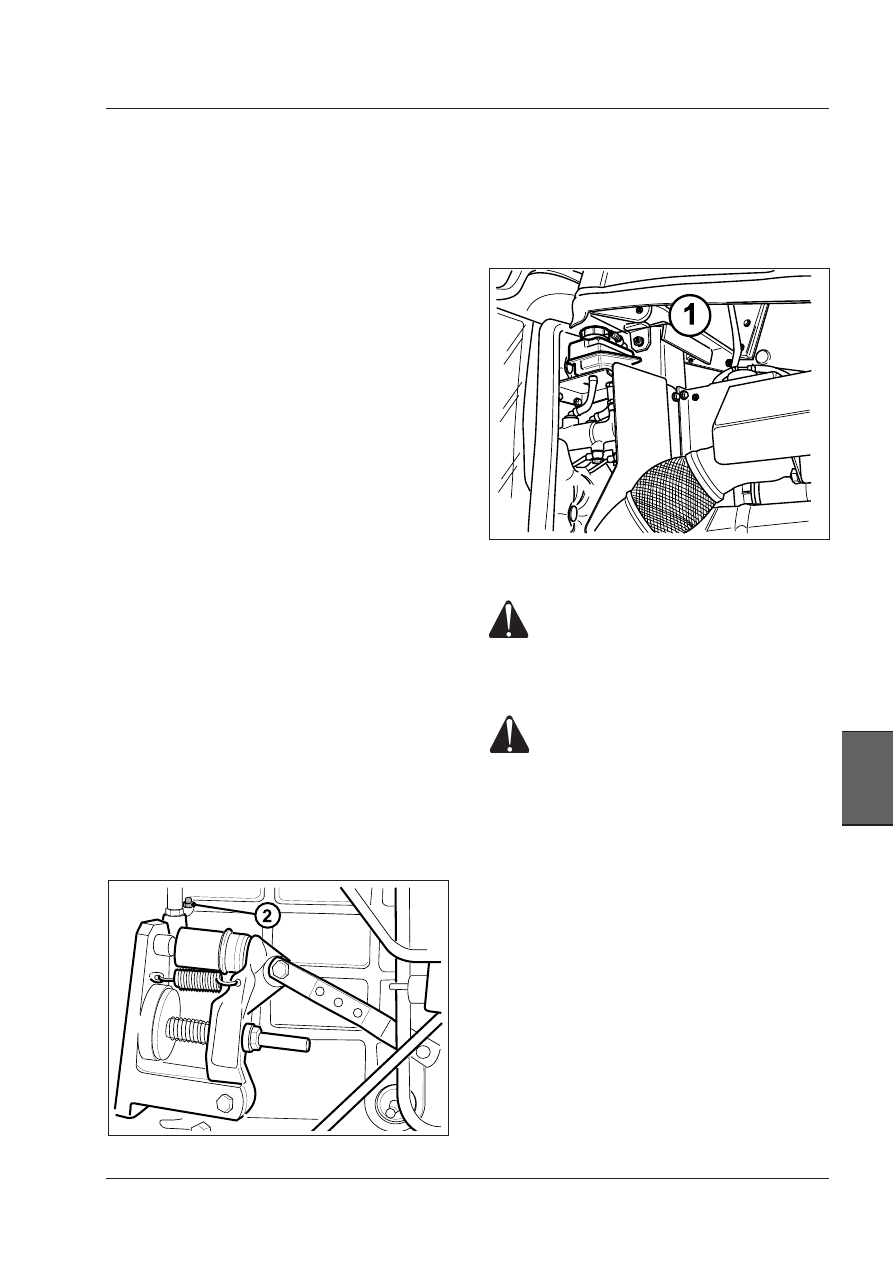

1 - Make sure that the reservoir (1) is full.

2 - Thoroughly clean the area around the bleed screw.

3 - Fully depress the left-hand brake pedal.

Meanwhile, unscrew the bleed screw (2) a half-turn

and allow any air and oil to flow out. Re-tighten the

bleed screw and release the pedal.

4 - Repeat this operation until bubble-free oil flows from

the bleed screw.

5 - Make sure that the clutch pedal travel is firm and not

spongy.

6 - Carry out the operations described above for the

right-hand brake pedal.

7 - On completion of bleeding, top up the fluid level in

the reservoir (1).

NOTE: Never reuse previously bled oil without having

first filtered it.

CAUTION: If you need to open the bonnet, follow the procedure indicated under “How to open the bonnet”.

WARNING: Always use specific personal safety devices for each operation.

WARNING: Maintenance operations must be carried out with the engine off. Check that the gear and the par-

king brake are both engaged and that the ignition key has been removed.

WARNING: Beware of burns caused by hot tractor and engine parts.

[4.1.n]

WARNING: When changing or topping up the

brake fluid in the reservoir (1), be abso-

lutely sure to use the correct type of fluid as a

mineral-based oil is used on these machines.

Consult the Lubricant and Fuel chart for the

oil type.

WARNING: The oil in the brake circuits has

been studied to operate at a temperature of

100°C but only if not polluted by other sub-

stances, e.g. water in considerable quantities

will turn into vapour and prevent the braking

system from operating in the correct way.

Take the necessary precautions to prevent

water from penetrating into the system: pro-

tect the front axle and the components in the

braking system when the tractor is washed;

store oil in sheltered places where water

cannot infiltrate. If you think that there is

water in the braking system you must con-

tact your dealer’s specialized personnel and

have it removed. In this case, the rear brake

cylinders will have to be demounted and

emptied and particularly the brake housing

of the front axle which, being the lowest part

of the system, is the one most exposed to this

type of fault.