Tractors X60 Series. Manual - part 46

183

Maintenance

7

50 HOUR MAIN SERVICE

WARNING: To open the bonnet, follow the procedure indicated under “How to open the bonnet”.

WARNING: Always use specific personal safety devices for each operation. Beware of burns caused by hot water

and engine parts.

[4.1.n]

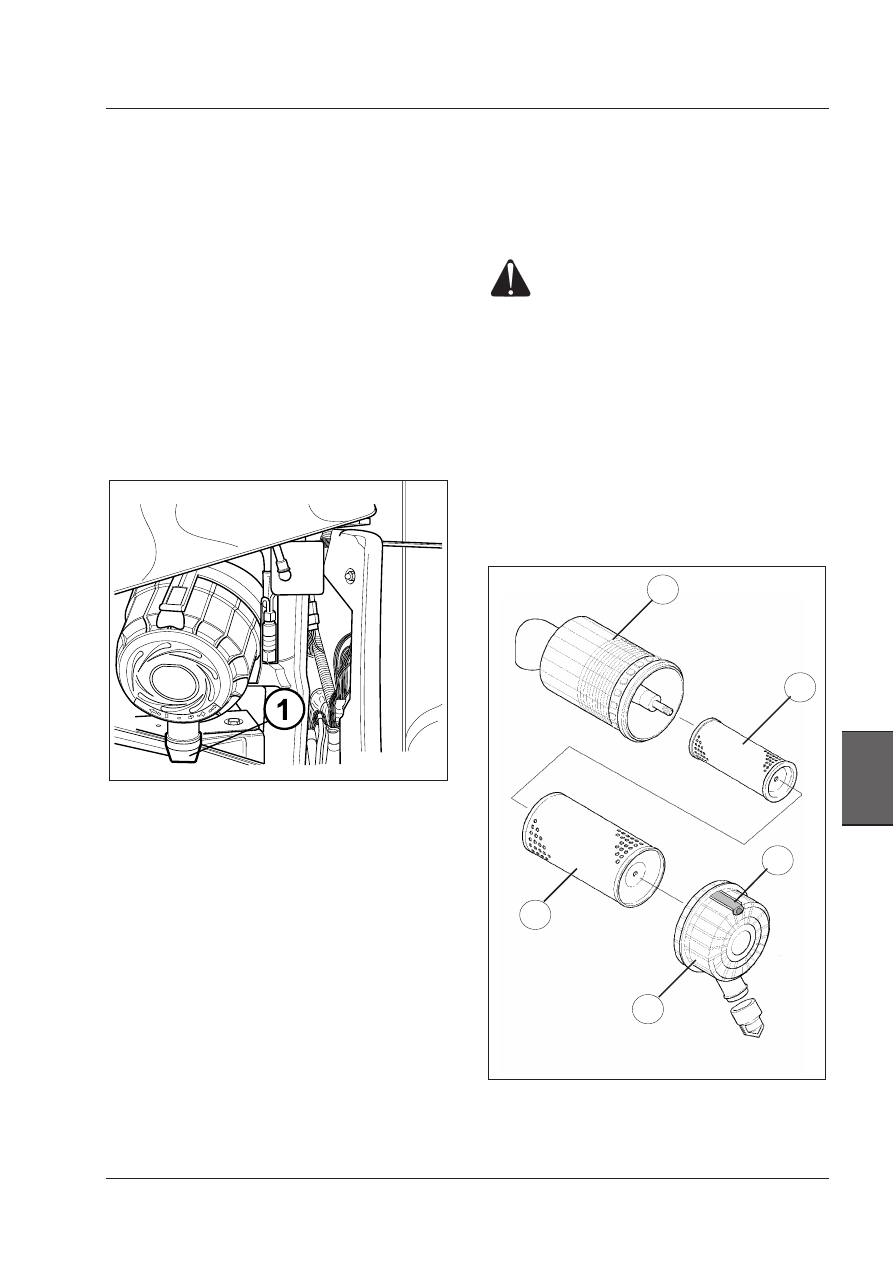

Engine air filter discharge valve

(if equipped).

Discharge the dust deposits and sediments each day

by pressing the rubber valve (1) on the air filter housing.

Install a new dust valve if damaged, or not operating

correctly.

NOTE: The discharge valve is not available if an auto-

matic dust ejector is fitted.

IMPORTANT: A new rubber dust valve MUST be installed

every 1000 hours.

Dry air filter outer cartridge

WARNING: Always stop the engine before

demounting the filter elements.

Periodically, remove the cover (2) (Pull out the yellow tab

(1), turn the cover (2) anti-clockwise and remove), take out

the external cartridge (3) from the container (4) and clean

it (this operation should be carried out more frequently

if you work in a very dusty environment or the indicator

on the instrument panel lights up). DO NOT remove the

inner cartridge (4).

See the procedure for disassembling, cleaning and re-

placing of the cartridges of the dry air filter in the Regular

Service at 1000 work hours in this section of the manual.

1

2

5

4

3