Snowmobile Arctic Cat (2002 year). Manual - part 162

9-126

AG322D

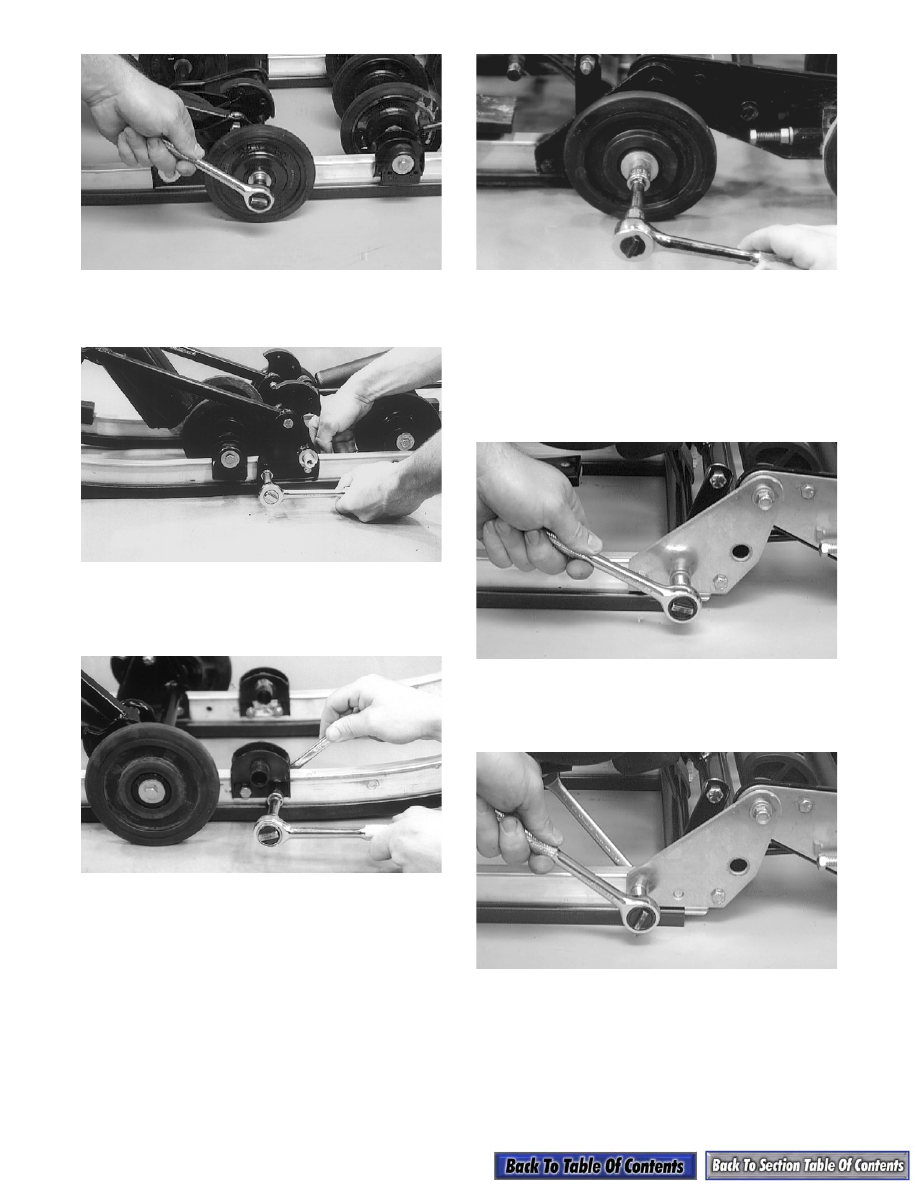

5. Remove the three cap screws and lock nuts secur-

ing the front arm bracket to the slide rail.

AG323

6. Remove the two cap screws and lock nuts securing

the center inner idler wheel bracket to the slide

rail.

AG390

7. Remove the cap screws and large flat washers

securing the center pivot idler wheels; then

remove the idler wheels.

AG600

8. Remove the two cap screws and lock nuts securing

the auxiliary wheel bracket.

9. Remove the cap screw, lock nut, and two washers

securing the spring block.

10. Remove the long cap screw securing the lower

rear arm assembly to the slide rails.

AG332D

11. Remove two cap screws securing each of the artic-

ulating frame brackets; then remove the articulat-

ing skid frame. Account for spacers.

AG611D

12. Remove the cap screw and nut securing the spring

tension block to the slide rail. Account for the

washers.

13. With all bracket hardware removed, pull the slide

rail slowly forward and out of all brackets.