Snowmobile Arctic Cat (2002 year). Manual - part 151

9-82

0727-456

3. If the measurement obtained in step 2 is more than

specified, tighten the adjusting bolts. If the mea-

surement obtained is less than specified, loosen

the adjusting bolts. When the measurement is

within specification range, lock the adjustment by

bottoming the jam nuts against the axle housings.

NOTE: Vigorously push the underside of the

track up and down. Track must not hit the top of

the tunnel or slap the skid frame.

4. After correct track tension is obtained, check track

alignment (see Track Alignment in this sub-sec-

tion).

NOTE: Track tension and track alignment are

interrelated; always check both even if only one

adjustment seems necessary. Always establish

correct track tension before checking and/or

adjusting alignment.

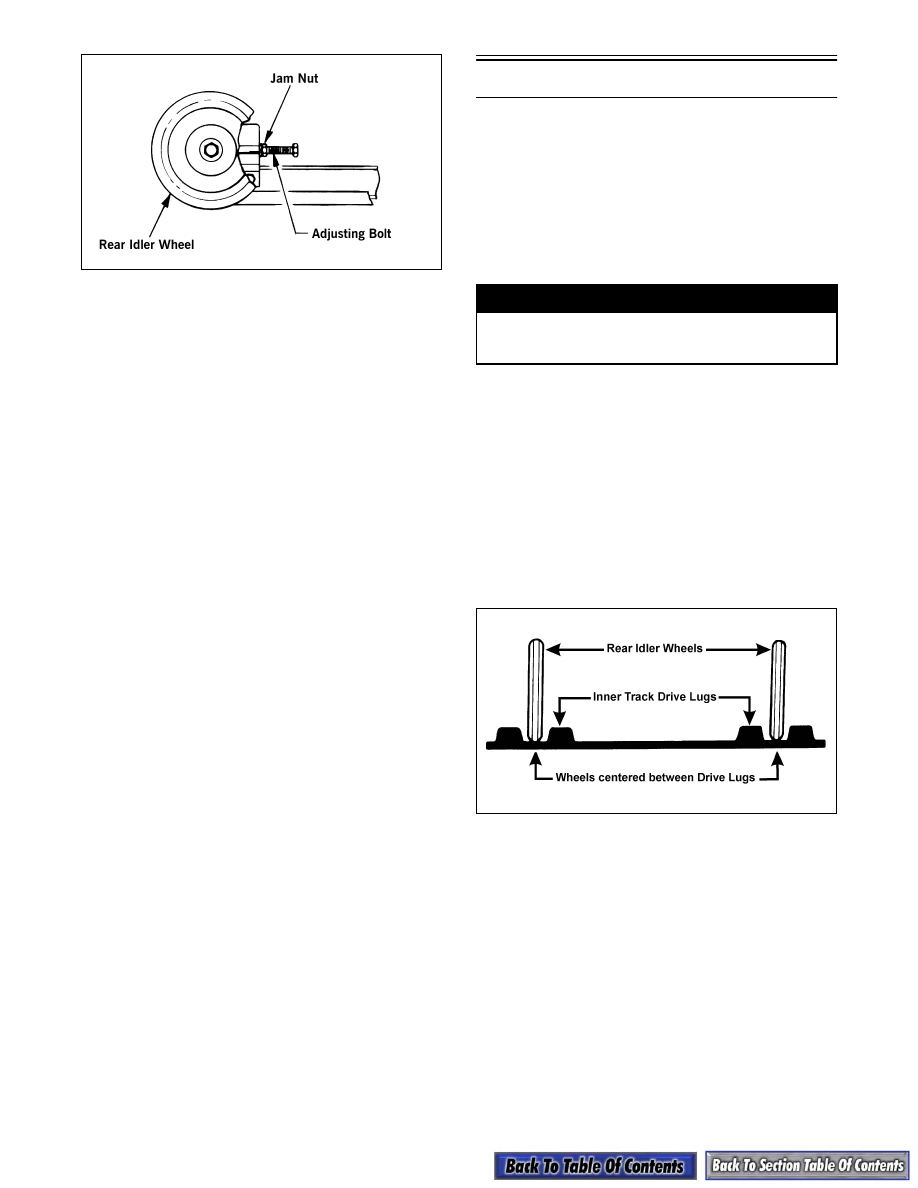

Track Alignment

NOTE: Proper track alignment is when the rear

idler wheels are equidistant from the inner drive

lugs on the inside surface of the track.

CHECKING

1. Using a shielded safety stand, raise the rear of the

snowmobile off the floor making sure the track is

free to rotate.

2. Start the engine and accelerate slightly. Use only

enough throttle to rotate the track several revolu-

tions. SHUT THE ENGINE OFF.

NOTE: Allow the track to coast to a stop. Do not

apply the brake because it could produce inaccu-

rate alignment conditions.

3. When the track stops rotating, check the relation-

ship of the rear idler wheels and the inner track

drive lugs. If the distance from the idler wheels to

the inner drive lugs is the same on both sides, no

adjustment is necessary.

725-070A

4. On the side of the track which has the inner drive

lugs closer to the rear idler wheel, loosen the

adjusting bolt jam nut; then rotate the adjusting

bolt clockwise 1-1 1/2 turns.

5. Continue to check the track alignment and make

the necessary adjustments until proper alignment

is obtained.

6. After proper track alignment is obtained, lock the

jam nut against the axle housing.

NOTE: Make sure correct track tension is main-

tained after adjusting track alignment.

NOTE: Field test the track under actual condi-

tions and, after the field test, check track align-

ment and track tension; adjust as necessary.

! WARNING

The tips of the skis must be positioned against a

wall or similar object for safety. Keep hands, feet,

and clothing away from moving components.