Snowmobile Arctic Cat (2002 year). Manual - part 148

9-70

AG512D

Rear Shock Absorber

and Shock Links

NOTE: Before removing the skid frame by using

the Rear Suspension Spring Tool (p/n 0144-311),

remove the spring from the adjusting cam.

NOTE: The skid frame must be removed for this

procedure (see Removing Skid Frame in this sub-

section).

DISASSEMBLING

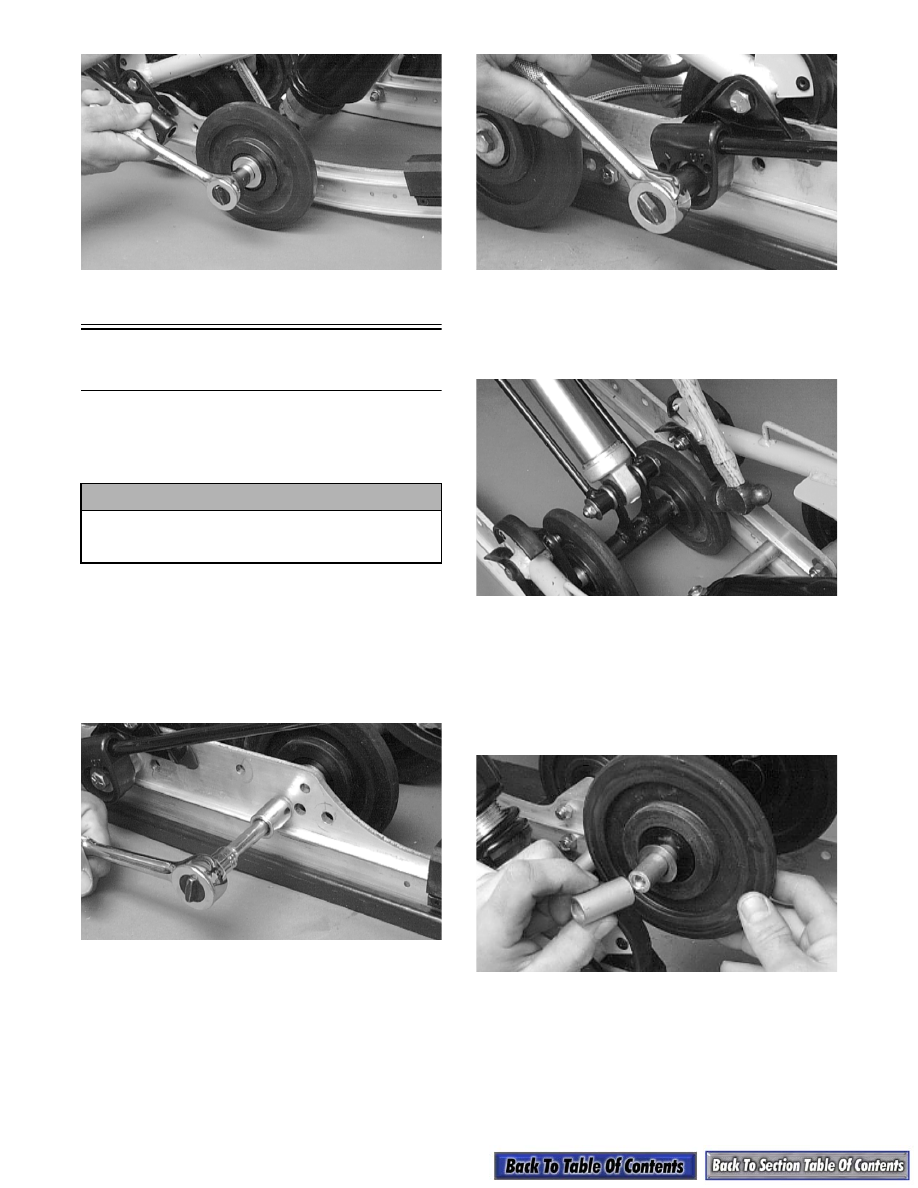

1. Remove the rear inner idler wheels (see Rear Inner

Idler Wheels in this sub-section).

AG592D

2. Note the hole location that the spring slides are in;

then remove the cap screws and flat washers

securing the spring slides to the rails. Account for

slide blocks.

AG662D

3. Tap the idler wheel assembly rearward until it

clears the mounting brackets; then lift the idler

wheel assembly upward until the shaft clears the

rails.

AG569D

NOTE: Lay components out in order as they are

removed.

4. Remove the spacer, washer, idler wheel with

inserts, washer, and inner bushing. Repeat the

same procedure on the other side of the shock

pivot bracket. Remove the idler wheel axle.

AG492D

! CAUTION

Care must be taken when removing the spring

from the adjusting cam or damage or injury

could result.