Snowmobile Arctic Cat (2002 year). Manual - part 55

4-13

4

AH618D

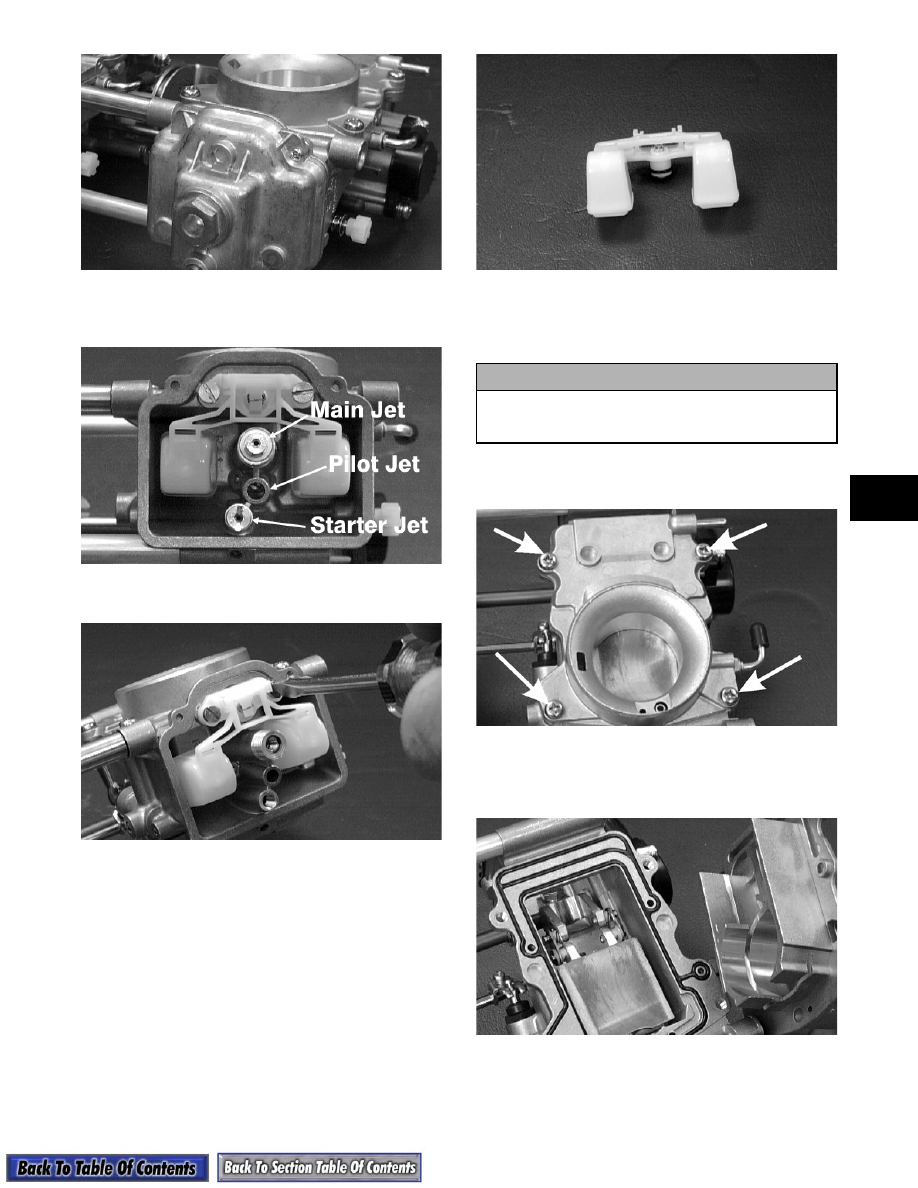

5. Remove the main jet (with washer), pilot jet, and

starter jet.

AH619DA

6. Remove the screws securing the float assembly.

AH620D

7. Remove the float assembly by lifting it up and out

of the mixing body. Account for the O-ring.

AH621D

NOTE: It may be necessary to use a spray lubri-

cant such as WD-40 to aid in removing the float

assembly.

8. Remove the Phillips-head screws securing the

funnel assembly to the mixing body.

AH622DA

9. Move the throttle lever to the full-open position;

then remove the funnel assembly. Account for the

gasket.

AH623D

10. Move the throttle lever slightly open; then rotate

the throttle valve out of the mixing body.

! CAUTION

To remove the throttle valve, the jet needle must

be removed or damage to the jet needle will

result.