Snowmobile Arctic Cat (2002 year). Manual - part 13

2-35

2

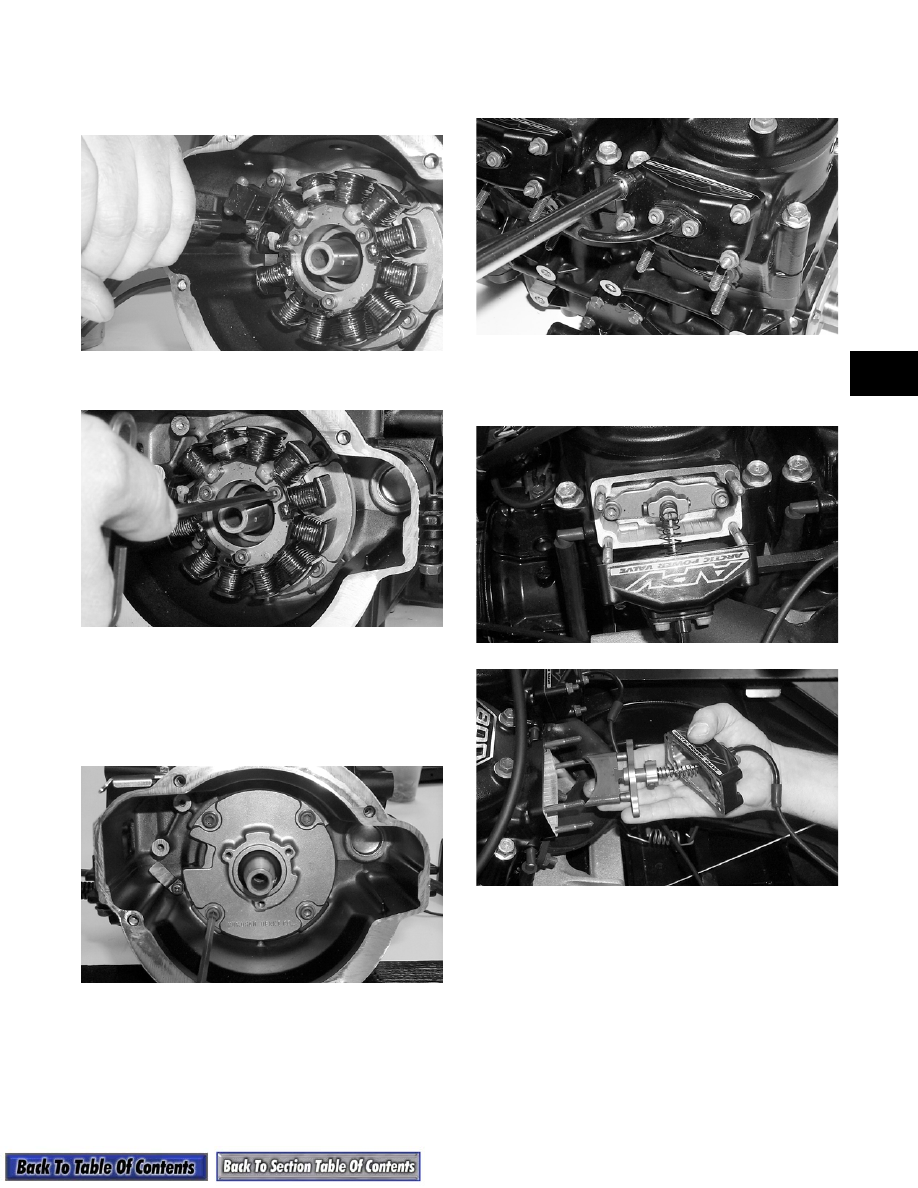

5. Remove the two screws securing the timing

sensor; then loosen the screws securing the wiring

harness retainer tab. Remove the timing sensor

from the crankcase.

AP131

6. Remove the cap screws securing the stator.

AP132

7. Remove the rubber grommet from the stator

wiring harness. Slide the stator free of the

crankshaft and remove.

8. Remove the cap screws securing the stator backing

plate. Remove the plate from the crankcase.

AP133

9. Remove the nuts securing the APV covers to the

cylinders; then slide the covers back to expose the

valves.

AP134

10. Remove the cap screws securing the valves to the

cylinders; then remove the APV assemblies and

set them aside.

AP120

AP121

11. Remove the three cap screws securing the

thermostat cap; then remove cap, rubber gasket,

and thermostat.

12. Remove the cap screws securing the thermostat

manifold to the cylinder heads. Remove the

manifold and discard the gaskets.