Snowmobile Arctic Cat (2002 year). Manual - part 12

2-31

2

AN414D

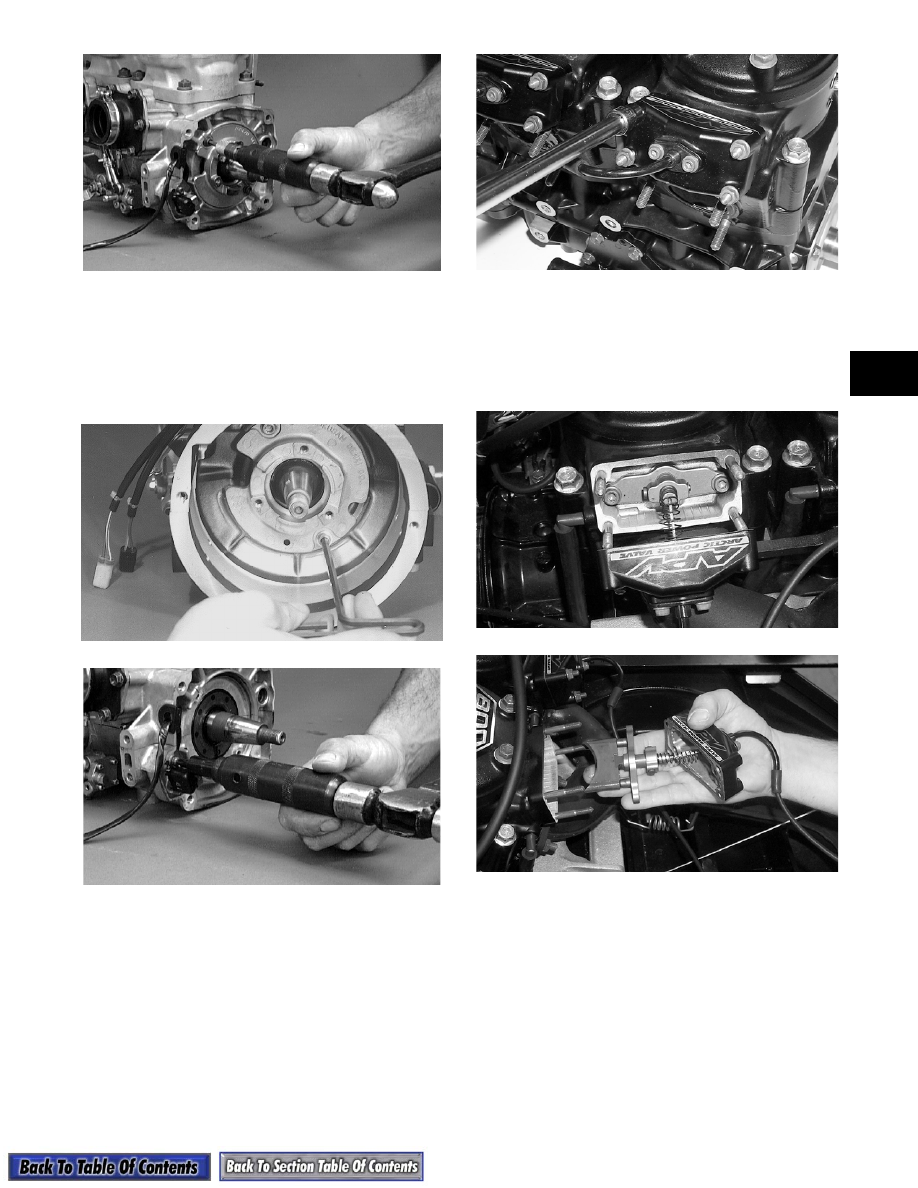

NOTE: The stator plate screws had Loctite

applied to the threads during assembly. Using an

impact driver, apply a sharp blow to the head of

each screw to break the Loctite loose before

removal.

7. Remove the ignition timing sensor.

AR107

AN415D

8. Remove the three cap screws securing the

thermostat cap; then remove the cap, gasket, and

thermostat.

9. Remove the nuts securing the APV covers to the

cylinders; then slide the covers back to expose the

valves.

AP134

10. Remove the cap screws securing the valves to the

cylinders; then remove the APV assemblies and

set them aside.

NOTE: The following illustrations are the 500 cc.

Other models may vary slightly.

AP120

AP121

11. Remove the spark plugs.

12. Remove the cap screws with O-rings securing the

cylinder head(s); then separate from the cylinders.

Account for the O-rings.

13. Remove the oil-injection hose from each cylinder

and the crankcase nozzle.