COMBINE HARVESTER AW70V, VNQ, AW82V, VNQ. Manual - part 22

Periodic Inspection

89

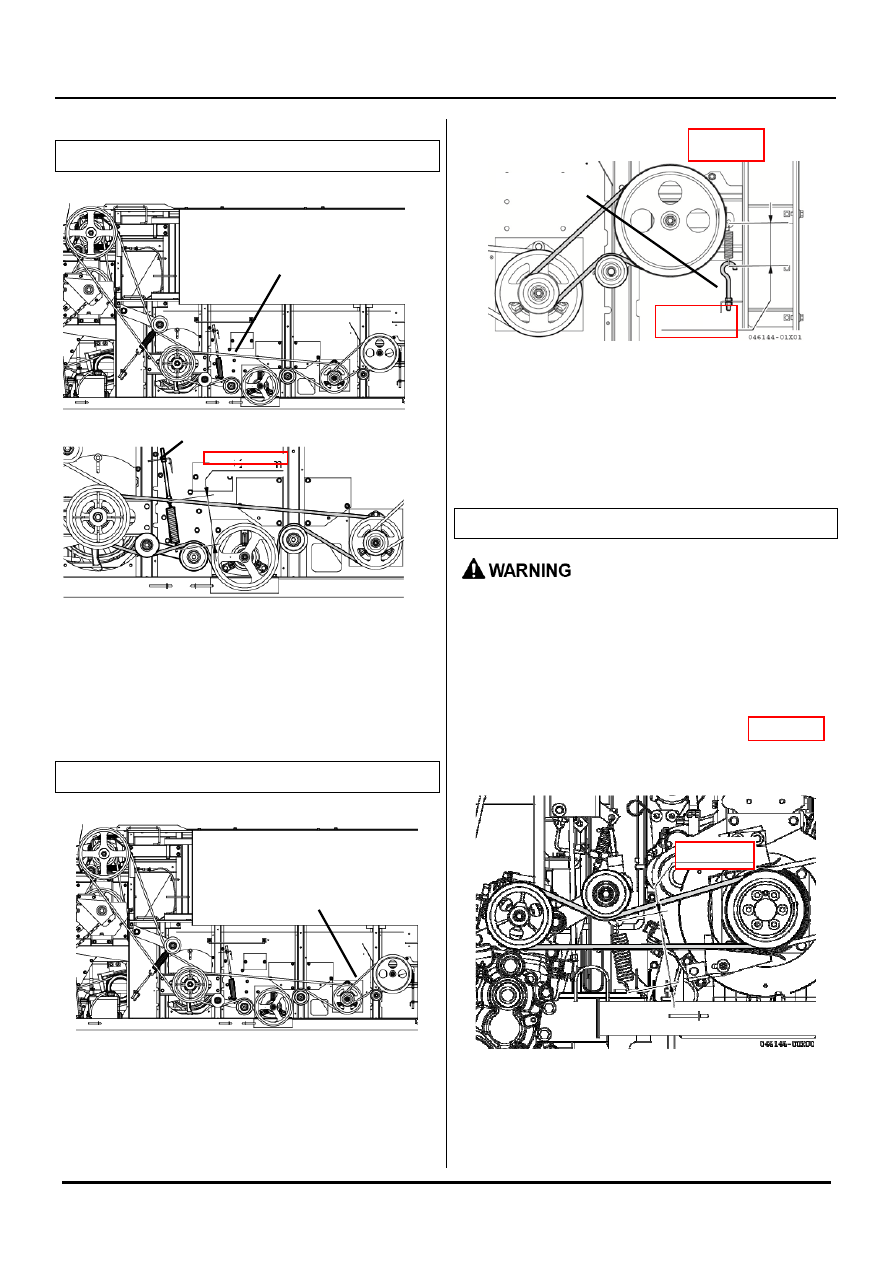

Screening belt

<Adjusting>

1. Remove the lower cover of the threshing section.

2. Loosen the lock nut and turn the adjusting nut to

change the spring length.

3. Fix it with the lock nut.

Swing separator drive belt

Adjust the tension spring length to 106±2mm.

<Adjusting>

1. Remove the lower cover of the threshing section.

2. Loosen the lock nut and turn the adjusting nut to

change the spring length.

3. Fix it with the lock nut.

Transmission drive belt

Be sure to fix the safety lock of the header.

Otherwise, it may fall down rapidly and

cause injuries.

<Adjusting>

1. Loosen the lock nut, and use the nut to adjust the

hook length of traveling tension spring to 150±2mm.

2. Fix it with the lock nut.

Screening belt

Adjusting part

198

±

2mm

106

±

2mm

Adjusting part

Swing separator drive belt

150

±

2mm