COMBINE HARVESTER AW70V, VNQ, AW82V, VNQ. Manual - part 23

Periodic Inspection

93

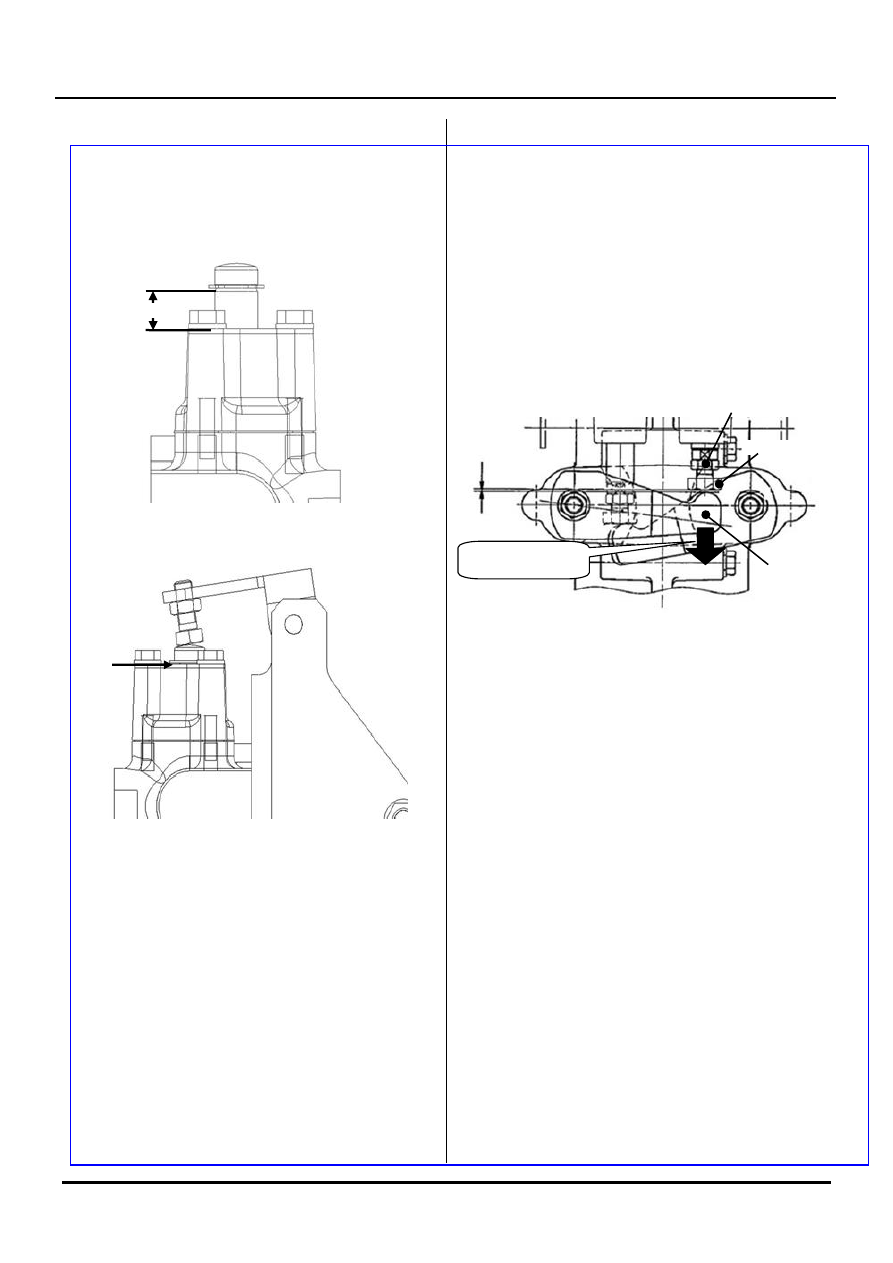

The spool retaining ring clearance on the upper side of

the actuator when the turning lever is fully turned down

G: 0-1 mm (both right and left side)

<The turning lever is in the neutral position>

<The turning lever is fully turned down>

If dimension G is more than the specified dimension,

the following problem may occur.

- Turning with one of the side clutch brakes engaged

cannot be performed at an early stage.

[Note]

Be sure to lock with the nut.

4. Clearance adjustment between the SC lever and

the machine bolt attached at the bottom of the

actuator.

The clearance between the machine bolt and the SC

lever while taking the play in the SC lever at the bottom.

J: 0-0.5 mm (both right and left)

[Note]

Make sure that dimension J is not a minus value.

(SC lever is being pushed.)

Be sure to lock with the nut.

If dimension J is more than the specified dimension, the

following problem may occur.- Turning with one of the

side clutch brakes engaged cannot be performed at an

early stage.

If dimension J is a minus value, the following problem

may occur.

- Parts inside the transmission become worn

- Transmission oil temperature increases

5. Checks after adjustment

Machine turns with one of the side clutch brakes

engaged (inner crawler stops) when the turning

lever is fully pushed down. (Both right and left)

Turning with one of the side clutches disengaged,

gradual turning, or turning with one of the side

clutch brakes engaged, can be performed

depending on the pushing angle of the turning

lever. (Both right and left)

The response that the operator receives from the

right and left sides is the same.

Nut is not loose and adjustment is not displaced

after the test operation.

G

G

Lock nut

Machine bolt

SC lever

SC lever play

direction