Yamaha XV1700P, XV1700PC. Service Manual - part 9

3 - 24

CHK

ADJ

MEASURING THE COMPRESSION PRESSURE

7. Remove:

• spark plug

CAUTION:

_

Before removing the spark plugs, use com-

pressed air to blow away any dirt accumu-

lated in the spark plug wells to prevent it

from falling into the cylinders.

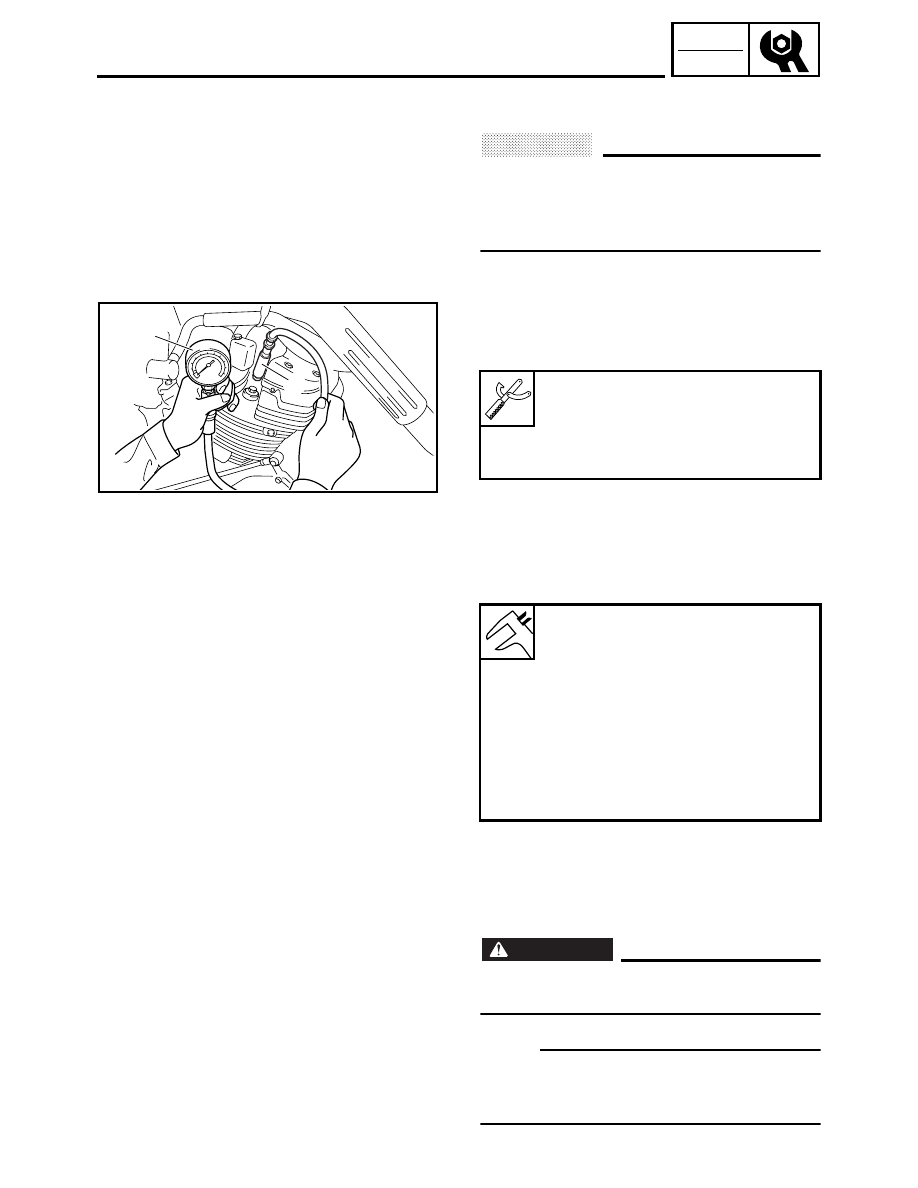

8. Install:

• compression gauge set 14/18 mm

1

• compression gauge adapter 12 mm

2

Compression gauge set 14/18 mm

YU-33223

Compression gauge adapter

12 mm

YU-33223-3

2

1

9. Measure:

• compression pressure

Out of specification

→

Refer to steps (c)

and (d).

▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼▼▼

a. Set the main switch to “ON”.

b. With the throttle wide open, crank the

engine until the reading on the compression

gauge stabilizes.

WARNING

_

To prevent sparking, ground all spark plug

leads before cranking the engine.

NOTE:

_

The difference in compression pressure

between cylinders should not exceed 100 kPa

(1 kg/cm

2

, 14 psi).

Compression pressure (at sea

level)

Minimum

1,040 kPa

(10.4 kg/cm

2

, 148 psi)

Standard

1,200 kPa

(12.0 kg/cm

2

, 171 psi)

Maximum

1,340 kPa

(13.4 kg/cm

2

, 191psi)