Suzuki GSX-R1000. Service Manual - part 3

0B-11 Maintenance and Lubrication:

7) Hold the motorcycle vertically and check the oil level

through the inspection window (3). The oil level

should be between the low level “L” and full level “F”.

Oil Level Inspection

1) Place the motorcycle on the side-stand.

2) Start up the engine and allow it to run for several

minutes at idle speed.

3) Turn off the engine and wait about three minutes.

4) Hold the motorcycle vertically and check the oil level

through the inspection window (1). The oil level

should be between the low level “L” and full level “F”.

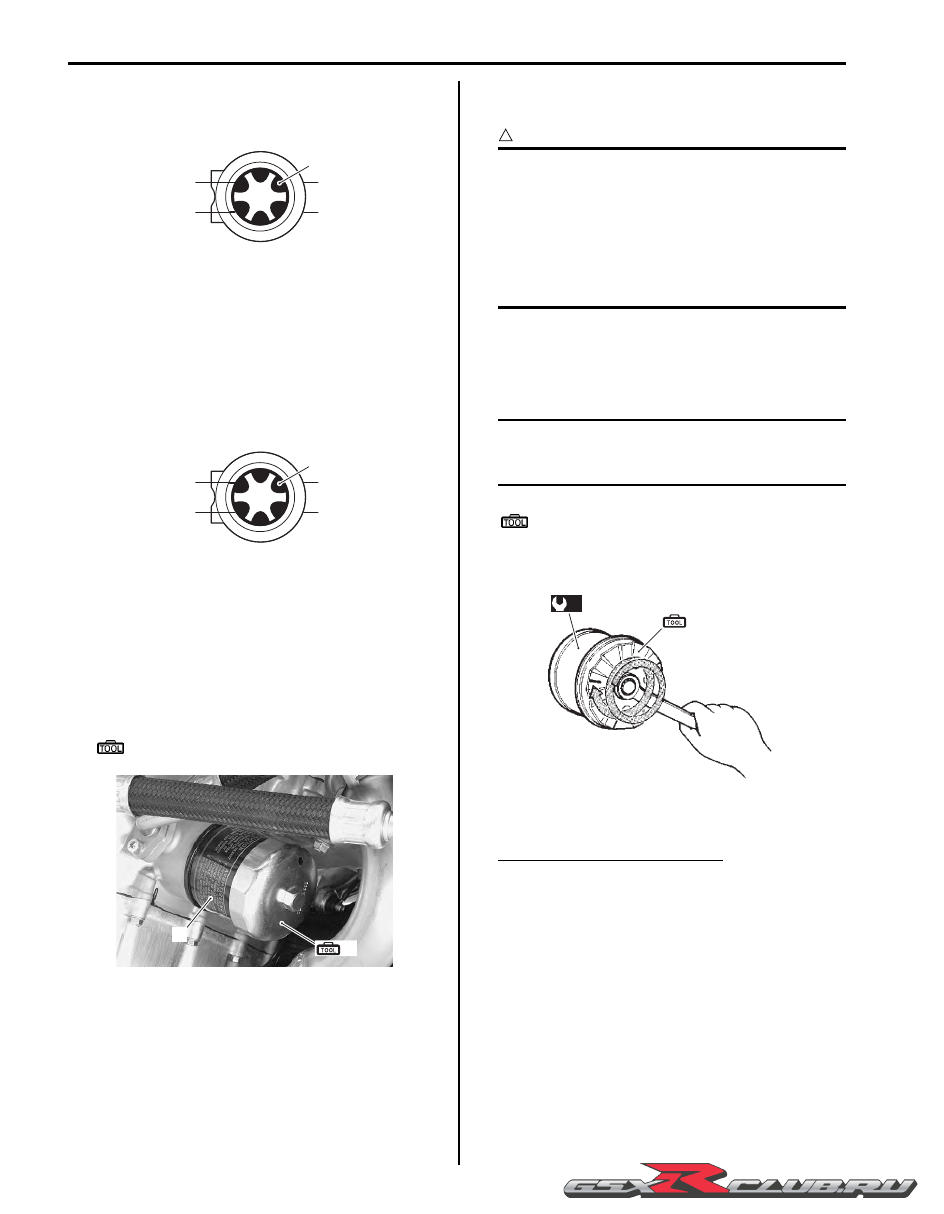

Oil Filter Replacement

1) Remove the right side cowling. Refer to “Exterior

Parts Removal and Installation” in Section 9D

(Page 9D-6).

2) Drain engine oil as described in the engine oil

replacement procedure.

3) Remove the oil filter (1) using the special tool.

Special tool

(A): 09915–40610 (Oil filter wrench)

4) Apply engine oil lightly to the O-ring of new oil filter,

before installation.

CAUTION

!

ONLY USE A GENUINE SUZUKI

MOTORCYCLE OIL FILTER.

Other manufacturer’s oil filters may differ in

thread specifications (thread diameter and

pitch), filtering performance and durability

which may lead to engine damage or oil

leaks. Also, do not use a genuine Suzuki

automobile oil filter on this motorcycle.

5) Install new oil filter. Turn it by hand until you feel that

the oil filter O-ring contacts the oil filter mounting

surface. Then, tighten the oil filter two full turns (or to

specified torque) using the special tool.

NOTE

To properly tighten the oil filter, use the

special tool. Never tighten the oil filter by

hand only.

Special tool

(A): 09915–40610 (Oil filter wrench)

Tightening torque

Oil filter (a): 20 N·m (2.0 kgf-m, 14.5 lbf-ft)

6) Add new engine oil and check the oil level is as

described in the engine oil replacement procedure.

Necessary amount of engine oil

Oil change: 2 800 ml (3.0/2.5 US/lmp qt)

Oil and filter change: 3 300 ml (3.5/3.0 US/lmp qt)

Engine overhaul: 3 600 ml (2.8/3.2 US/lmp qt)

F

L

3

I815H1020023-01

F

L

1

I815H1020024-01

(A)

1

I947H1020012-01

(a)

(A)

I823H1020041-01