Suzuki GSX-R1000. Service Manual - part 2

0A-9 General Information:

Specifications

Specifications

B947H10107001

NOTE

These specifications are subject to change without notice.

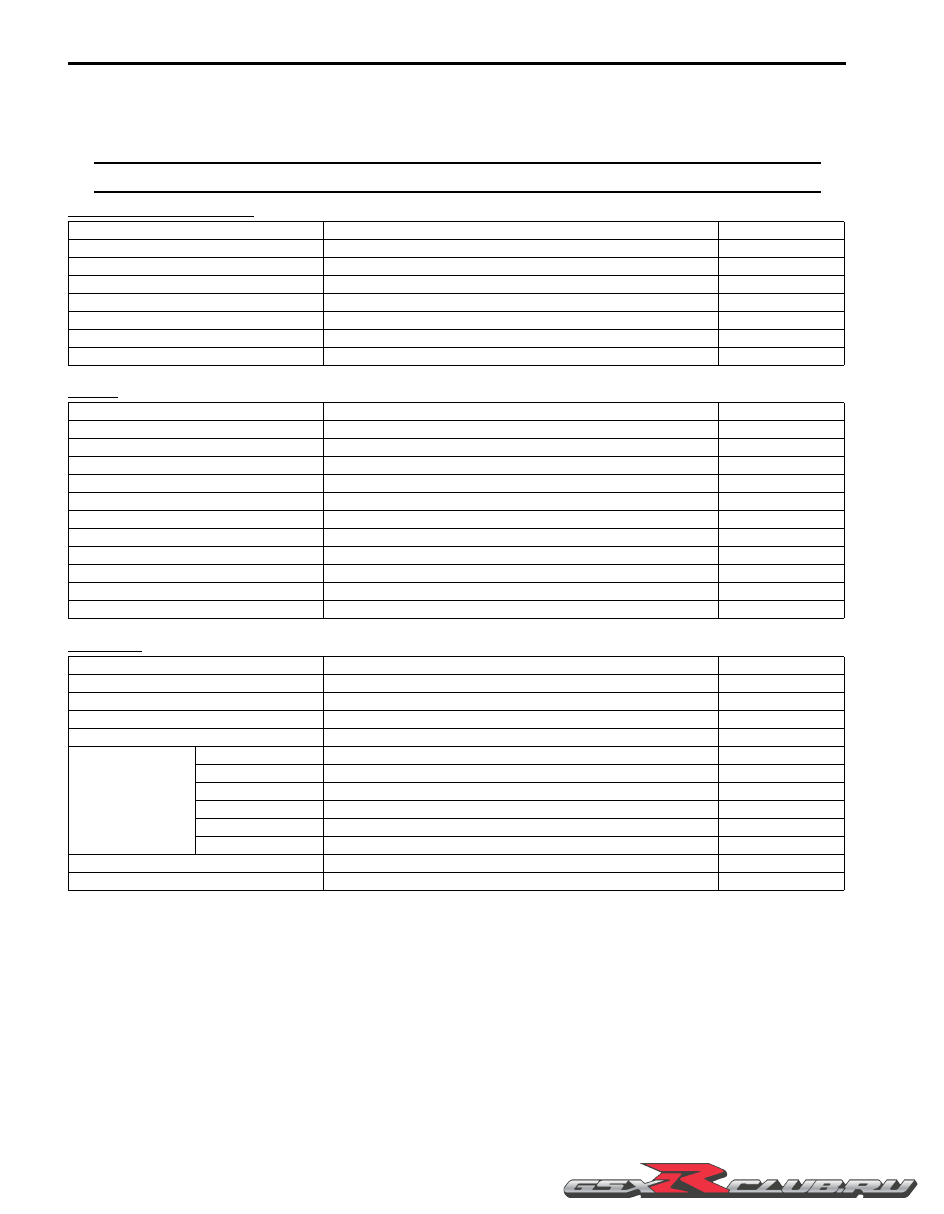

Dimensions and dry mass

Engine

Drive train

Item

Specification

Remark

Overall length

2 045 mm (80.5 in)

Overall width

720 mm (28.3 in)

Overall height

1 130 mm (44.5 in)

Wheelbase

1 405 mm (55.3 in)

Ground clearance

130 mm (5.1 in)

Seat height

810 mm (31.9 in)

Curb mass

205 kg (452 lbs)

Item

Specification

Remark

Type

4-stroke, Liquid-cooled, DOHC

Number of cylinders

4

Bore

74.5 mm (2.933 in)

Stroke

57.3 mm (2.256 in)

Displacement

999 cm

3

(61.0 cu. in)

Compression ratio

12.8 : 1

Fuel system

Fuel injection system

Air cleaner

Paper element

Starter system

Electric

Lubrication system

Wet sump

Idle speed

1 150

±

100 r/min

Item

Specification

Remark

Clutch

Wet multi-plate type

Transmission

6-speed constant mesh

Gearshift pattern

1-down, 5-up

Primary reduction ratio

1.617 (76/47)

Gear ratios

Low

2.562 (41/16)

2nd

2.052 (39/19)

3rd

1.714 (36/21)

4th

1.500 (36/24)

5th

1.360 (34/25)

Top

1.269 (33/26)

Final reduction ratio

2.470 (42/17)

Drive chain

DID50VAZ, 114 links