Suzuki Grand Vitara JB416 / JB420. Manual - part 31

1A-73 Engine General Information and Diagnosis:

DTC P0101: Mass Air Flow Circuit Range / Performance

S5JB0A1104017

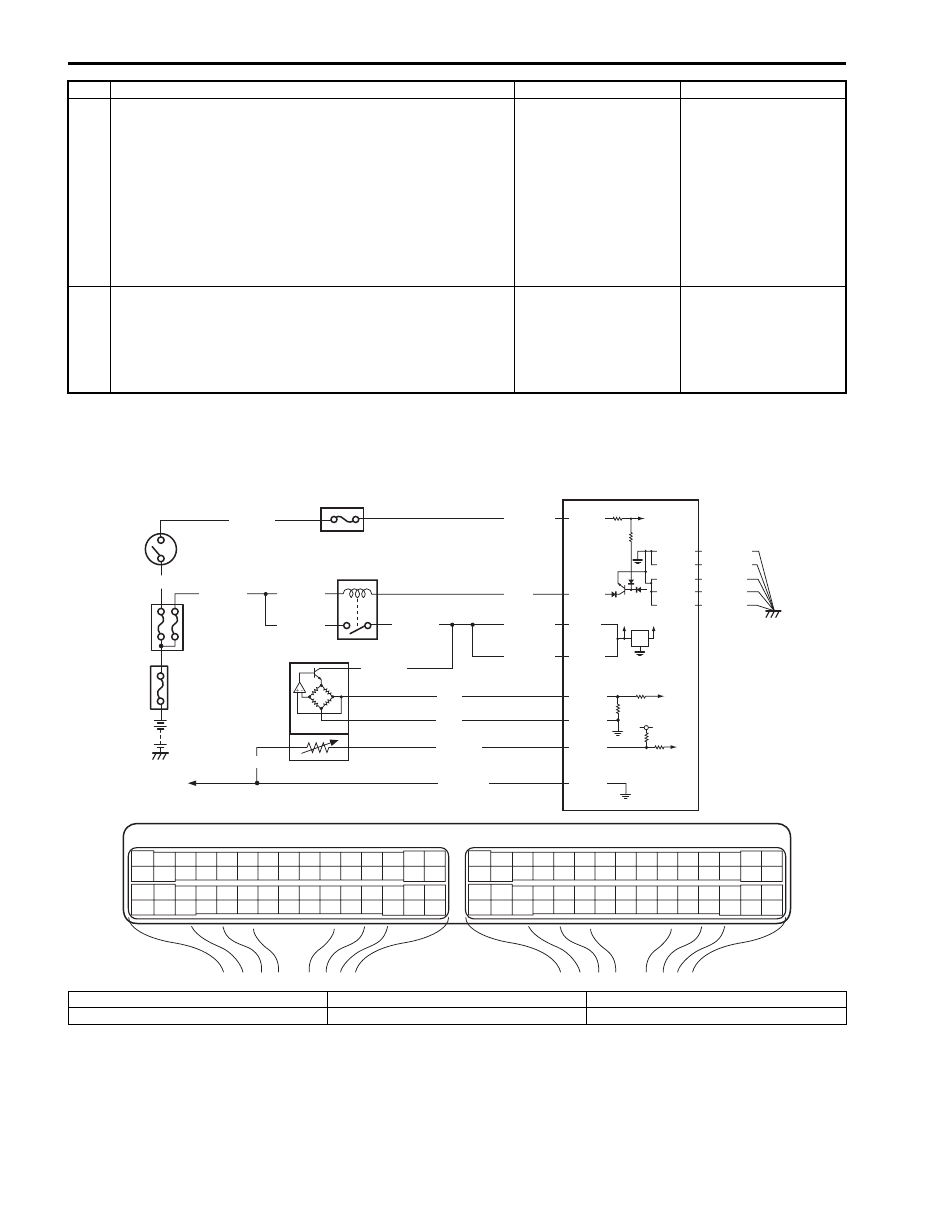

Wiring Diagram

10 HO2S heater control circuit check

1) Disconnect connector from ECM with ignition switch

turned OFF.

2) Check for proper connection of HO2S-2 heater circuit

terminal to ECM connector.

3) If connection are OK, measure wire resistance of sensor

heater control circuit at ECM connector between ECM to

HO2S-2.

Is measured wire resistance lower than 1

Ω

?

Go to Step 11.

Repair or replace

defective wire circuit.

11 HO2S-2 heater circuit check

1) Measure insulation resistance between control terminal

of HO2S-2 heater at ECM connector and vehicle body

ground.

Is measured resistance infinity?

Substitute a known

good ECM and recheck.

Repair or replace short

wire.

Step

Action

Yes

No

E23

C37

3

4

18

19

5

6

7

10

11

17

20

47

46

49

50

51

21

22

52

16

25

9

24

14

29

55

57

54 53

59

60

58

2

26

27

28

15

30

56

48

32

31

34

35

36

37

40

42

39 38

44

45

43

41

33

1

12

13

23

8

3

4

18

19

5

6

7

10

11

17

20

47

46

49

50

51

21

22

52

16

25

9

24

14

29

55

57

54 53

59

60

58

2

26

27

28

15

30

56

48

32

31

34

35

36

37

40

42

39 38

44

45

43

41

33

1

12

13

23

8

BLK/WHT

BLU/BLK

BLU/BLK

WHT/GRN

BLK/RED

BLK/RED

BLK/RED

BLK/YEL

BLU

12V

5V

5V

2

3

4

E23-29

E23-1

E23-60

BLU/BLK

E23-16

LT GRN

GRY/GRN

GRY/GRN

1

BLU/BLK

C37-25

C37-57

5

BLU

RED

C37-26

C37-27

C37-15

C37-29

C37-48

BLK/ORN

C37-58

C37-30 BLK/ORN

BLK/YEL

BLK/YEL

BLK/YEL

I5JB0A110033-01

1. MAF and IAT sensor

3. Main relay

5. To other sensors

2. Ignition switch

4. ECM