Nissan Versa Sedan. Manual - part 784

TM-42

< UNIT DISASSEMBLY AND ASSEMBLY >

[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

CAUTION:

• Do not reuse differential side oil seal.

• Do not tilt differential side oil seal.

• Do not damage clutch housing and transaxle case.

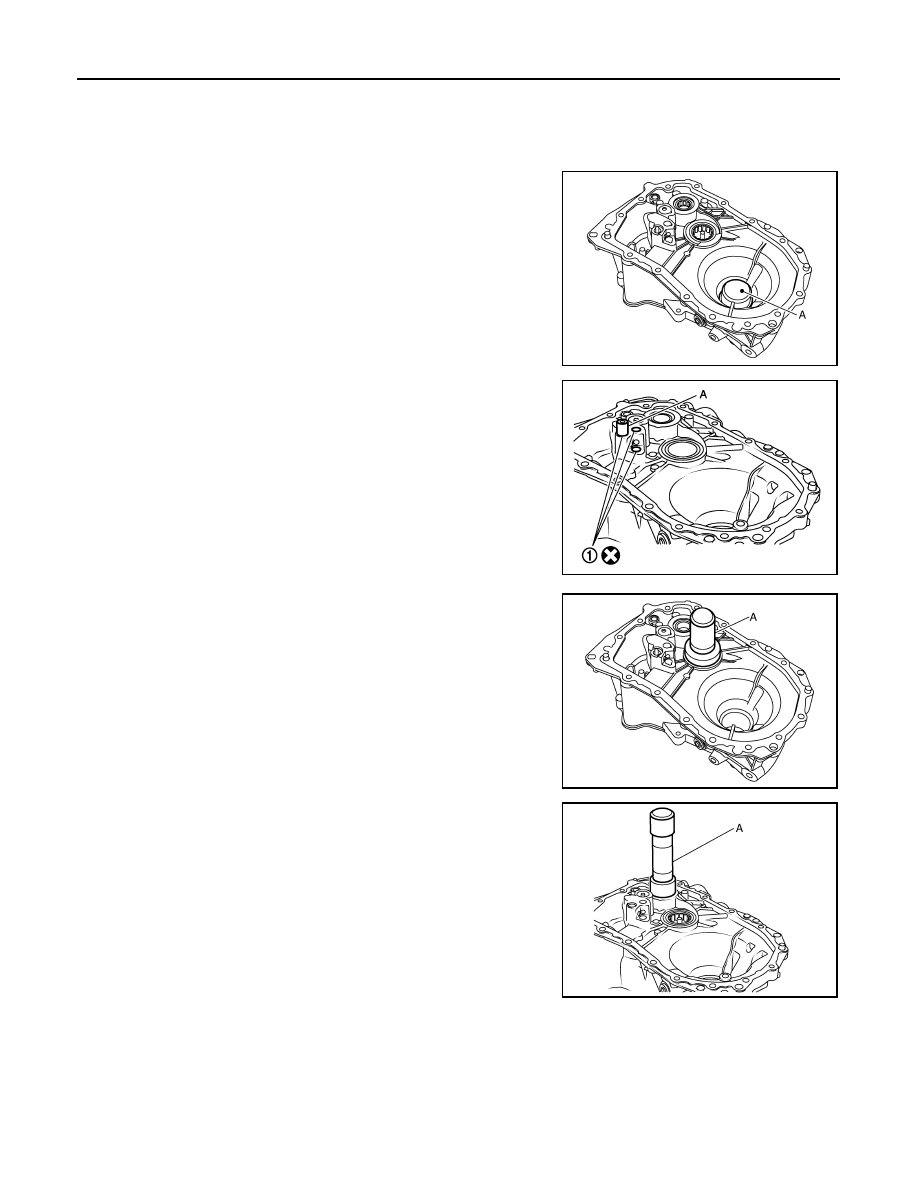

13. Install differential side bearing outer races until they reach clutch

housing and transaxle case, using Tool (A).

CAUTION:

Replace differential side bearing outer race and differential

side bearing as a set.

14. Install bushings (1) until they reach clutch housing, using suit-

able tool (A).

CAUTION:

Do not reuse bushings.

15. Install oil channel to clutch housing.

CAUTION:

Do not reuse oil channel.

16. Install mainshaft front bearing so that it becomes even with

clutch housing surface, using Tool (A).

17. Install input shaft front bearing so that it becomes even with

clutch housing surface, using Tool (A).

18. Install pinion gear, pinion shaft, and plug to clutch housing.

Tool number

: KV32300QAE ( — )

PCIB1549E

JPDIC0637ZZ

Tool number : ST33400001 ( — )

PCIB1544E

Tool number

: KV40100900 ( — )

PCIB1545E