Mazda 6. Manual - part 155

F–142

ON-BOARD DIAGNOSTIC

DTC P0500

A6E397001087W01

Diagnostic procedure

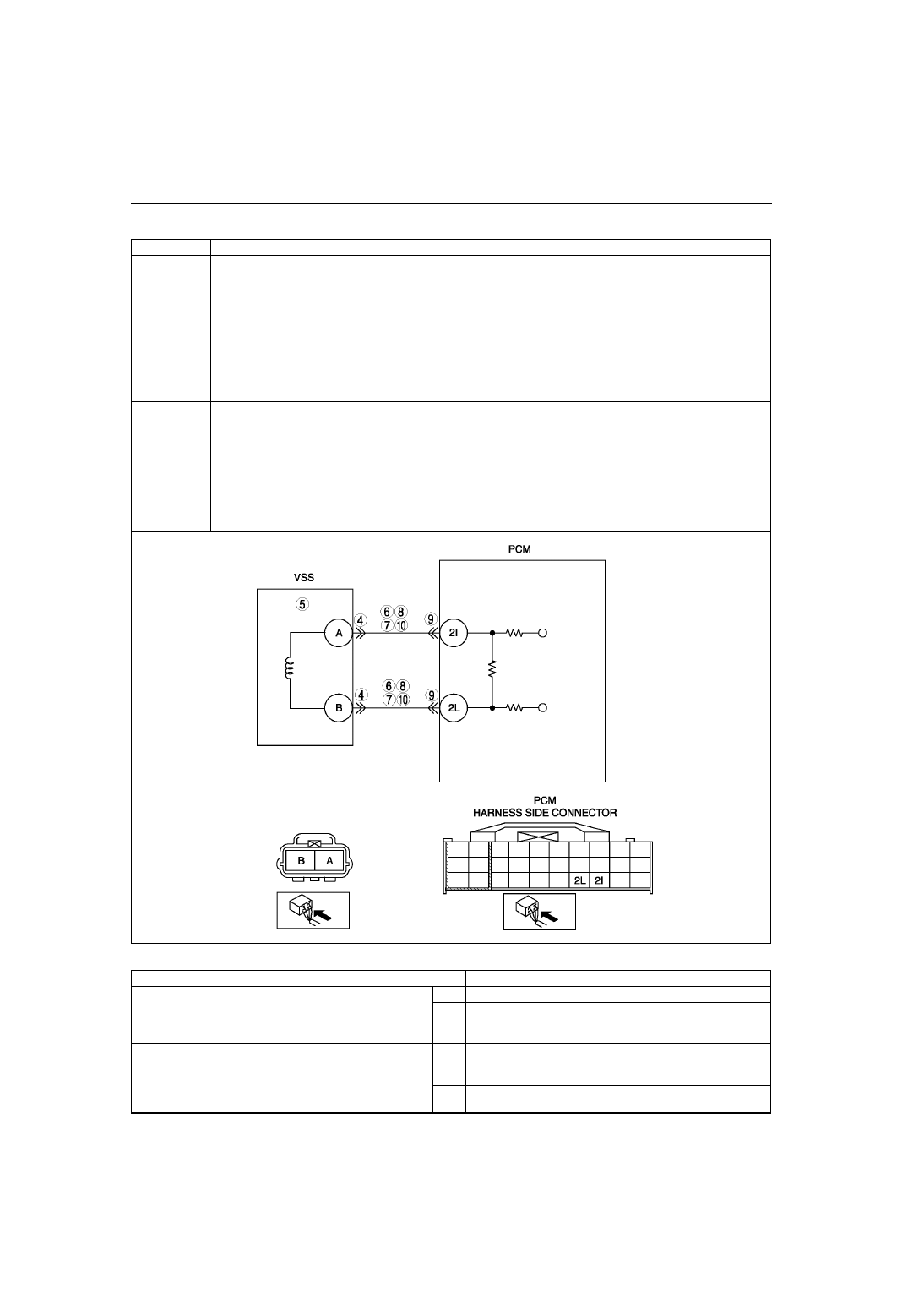

DTC P0500

Vehicle speed sensor (VSS) circuit malfunction (MTX vehicles without ABS)

DETECTION

CONDITION

• Vehicle speed signal does not input after following conditions are met:

— Gear is in other than neutral position

— Load is above 40%

— Engine speed is 2,000 rpm or above

Diagnostic support note:

• This is a continuous monitor (CCM).

• MIL illuminates if PCM detects the above malfunction conditions in two consecutive drive cycles or in one

drive cycle while the DTC for the same malfunction has been stored in the PCM.

• PENDING CODE is available if PCM detects the above malfunction condition during first drive cycle.

• FREEZE FRAME DATA is available.

• DTC is stored in PCM memory.

POSSIBLE

CAUSE

• VSS malfunction

• ABS/TCS/DCS malfunction

• Connector or terminal malfunction

• Open circuit between PCM terminal 2I and VSS terminal A

• Open circuit between PCM terminal 2L and VSS terminal B

• Short to ground between PCM terminal 2I and VSS terminal A

• Short to ground between PCM terminal 2L and VSS terminal B

• Short to power between PCM terminal 2I and VSS terminal A

• Short to power between PCM terminal 2L and VSS terminal B

• PCM malfunction

STEP

INSPECTION

ACTION

1

VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

• Has FREEZE FRAME PID DATA been

recorded?

Yes Go to next step.

No

Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2

VERIFY RELATED SERVICE INFORMATION

AVAILABILITY

• Check for related Service Information

availability.

• Is any related Service Information available?

Yes Perform repair or diagnosis according to available Service

Information.

• If vehicle is not repaired, go to next step.

No

Go to next step.