Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 231

ENGINE DRIVEABILITY AND EMISSIONS

6E–165

10

Using the DVM and check the injector signal circuit.

1. Ignition “On”, engine “Off”.

2. Disconnect the injector connector for the affected

cylinder.

3. Check the circuit for short to battery voltage

circuit.

Was the DVM indicated battery voltage?

—

Repair faulty

harness and

verify repair

Go to Step 12

11

Replace the injector for the affected cylinder.

Was the problem solved?

—

Verify repair

Go to Step 12

12

Is the ECM programmed with the latest software

release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved?

—

Verify repair

Go to Step 13

13

Replace the ECM.

Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobiliser system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobiliser System-ECM replacement” for

the ECM/Immobiliser linking procedure.

—

Verify repair

—

Step

Action

Value(s)

Yes

No

V

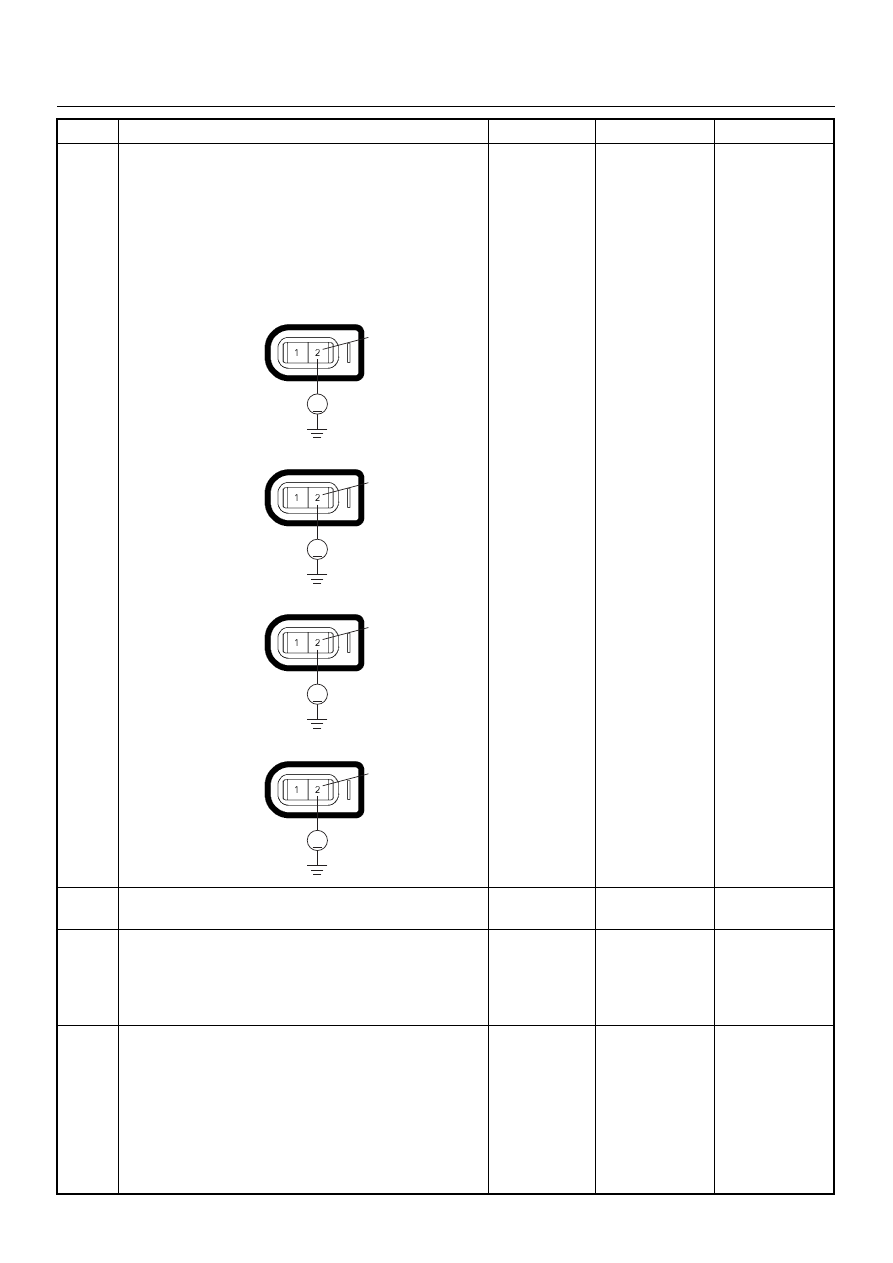

2

E-6

No.1 Cylinder

V

2

E-7

No.2 Cylinder

V

2

E-8

No.3 Cylinder

V

2

E-9

No.4 Cylinder