Content .. 1659 1660 1661 1662 ..

Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 1661

1-30 HEATING AND AIR CONDITIONING

GENERAL REPAIR PROCEDURE

OIL SPECIFICATION

•

The R-134a system requires a synthetic (PAG) compressor

oil whereas the R-12 system requires a mineral compressor

oil.

The two oils must never be mixed.

•

Compressor (PAG) oil varies according to compressor

model. Be sure to use oil specified for the model of

compressor.

Specified Compressor Oil

ZXL-100PG

(ISUZU PART NO.8-97101-338-0)

HANDLING OF OIL

•

The oil should be free from moisture, dust, metal powder,

etc.

•

Do not mix with other oil.

•

The water content in the oil increases when exposed to the

air. After use, seal oil from air immediately.

(R-134a PAG Compressor Oil absorbs moisture very easily

than R-12.)

•

The compressor oil must be stored in steel containers, not

in plastic containers.

COMPRESSOR OIL CHECK

The Oil used to lubricate the compressor is circulating with the

refrigerant.

Whenever replacing any component of the system or a large

amount of gas leakage occurs, add oil to maintain the original

amount of. oil.

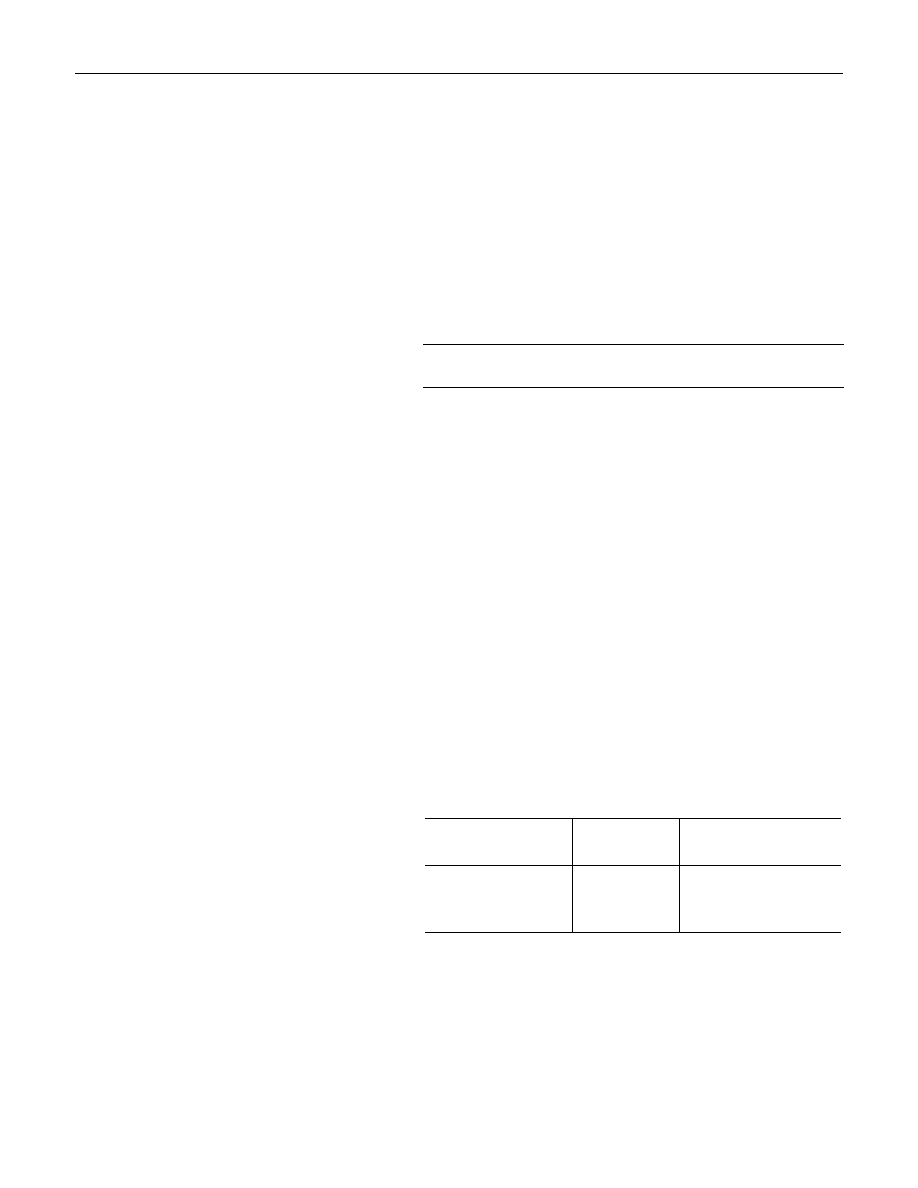

Oil Capacity

Capacity total in

system

DKS 15 CH

150 cc (5.0 fl.oz.)

Compressor

(Service parts)

charging amount

DKS 15 CH

150 cc (5.0 fl.oz.)