Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 145

6E–184

4JH1 ENGINE DRIVEABILITY AND EMISSIONS

10

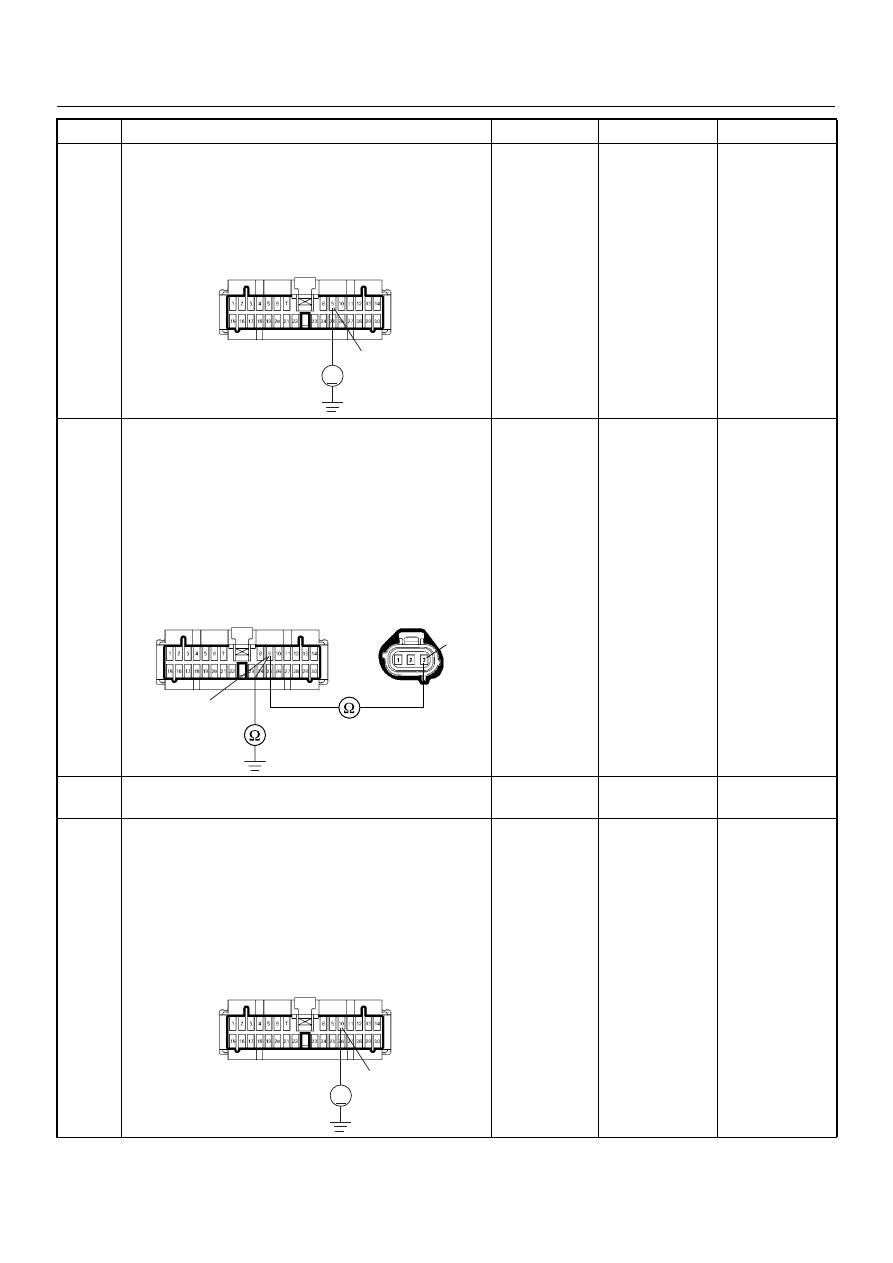

Using the DVM and check the VSS signal circuit.

1. Ignition “On”, engine “Off”.

2. Disconnect the meter connector.

3. Check the circuit for short to power supply circuit.

Was the DVM indicated specified value?

Less than 1V

Go to Step 11

Repair faulty

harness and

verify repair

11

Using the DVM and check the VSS signal circuit.

1. Ignition “Off”, engine “Off”.

2. Disconnect the VSS connector and meter

connector.

3. Check the circuit for open or short to ground

circuit.

If a open or short to ground circuit is found, repair the

faulty harness and verify repair.

Is the action complete?

—

Verify repair

—

12

Replace the speed meter.

Is the action complete?

—

Verify repair

—

13

Using the DVM and check the VSS signal circuit.

1. Ignition “Off”, engine “Off”.

2. Disconnect the meter connector and ECM

connector.

3. Ignition “On”.

4. Check the circuit for short to power supply circuit.

Was the DVM indicated specified value?

Less than 1V

Go to Step 14

Repair faulty

harness and

verify repair

Step

Action

Value(s)

Yes

No

9

V

B-24

3

9

E-44

B-24

10

V

B-24