Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 144

6E–180

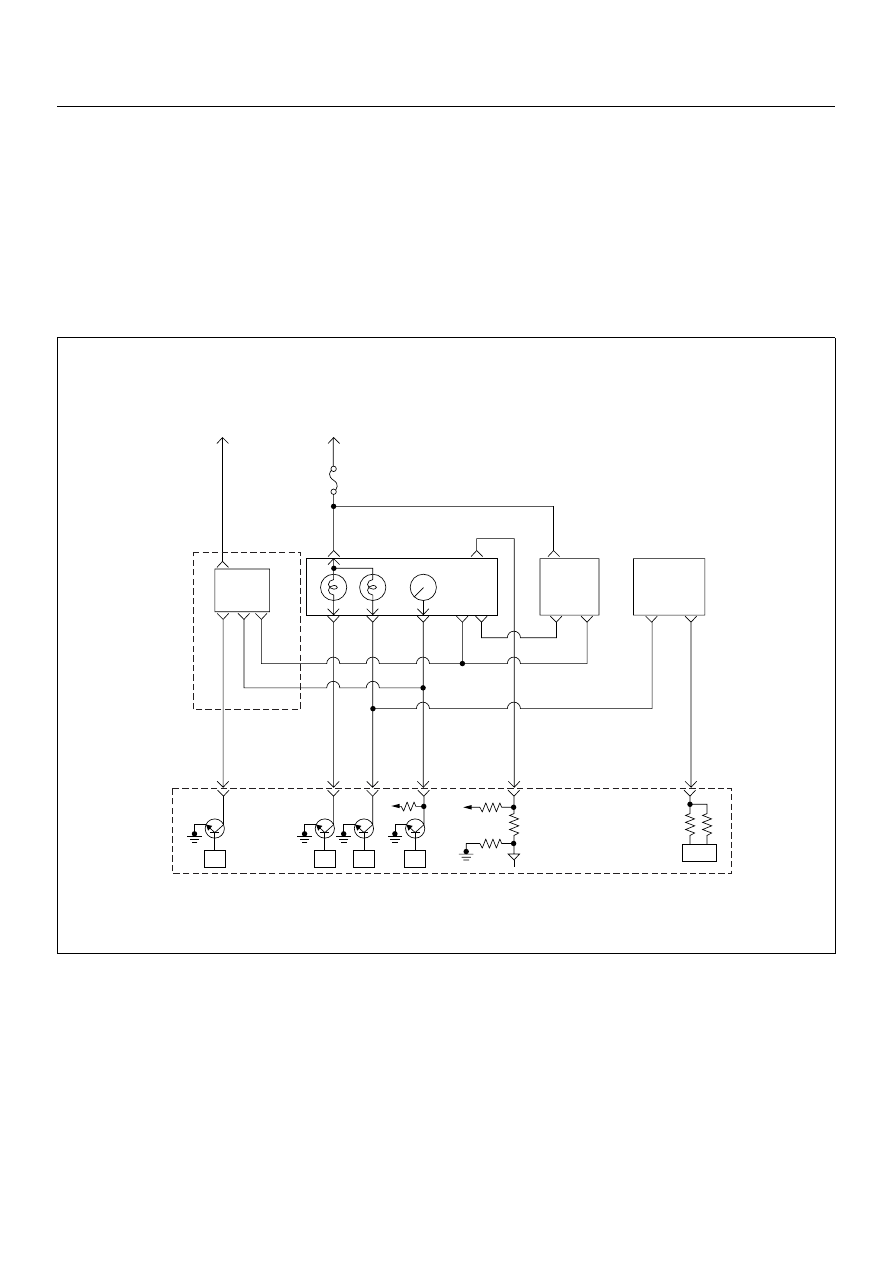

4JH1 ENGINE DRIVEABILITY AND EMISSIONS

DIAGNOSTIC TROUBLE CODE (DTC) P0500 (SYMPTOM CODE 1)

(FLASH CODE 24) VEHICLE SPEED SENSOR CIRCUIT HIGH INPUT

DIAGNOSTIC TROUBLE CODE (DTC) P0500 (SYMPTOM CODE A)

(FLASH CODE 24) VEHICLE SPEED SENSOR INPUT SIGNAL FREQUENCY

TOO HIGH

DIAGNOSTIC TROUBLE CODE (DTC) P0500 (SYMPTOM CODE B)

(FLASH CODE 24) VEHICLE SPEED SENSOR INCORRECT SIGNAL

Battery

Voltage

Ignition

SW

Meter

15A

A16

A7 A10

0.5

BLK/

YEL

Batt

Batt

0.5

RED/

WHT

29

0.5

ORG/

BLU

43

0.5

BRN/

YEL

42

0.5

BLK/

RED

27

0.5

BLU/

WHT

68

0.5

WHT

35

VSS

0.85

YEL

Imnobiliser

Control Unit

7

8

0.5

BRN/

YEL

IC

4P out

0.85

YEL

Glow

Check

Engine

Tacho

Meter

A/T

A1

TCM

µP

µP

µP

µP

Engine

Control

Module

(ECM)