Ford Fiesta (1989-1995). Instruction - part 19

7 Refer to the relevant Part of Chapter 4 for

details, and disconnect the accelerator cable

from the throttle linkage and support/adjuster

bracket. Where applicable, also disconnect

the choke cable. Position the cable(s) out of

the way.

8 On carburettor models, disconnect the fuel

supply hose from the fuel pump, and the

return hose from the carburettor.

9 On CFi models, detach the fuel hose at the

injector/pressure regulator unit, and the return

line, by compressing the couplings whilst

pulling the hoses free from their connections.

On EFi and SEFi models, unscrew the union

nut to detach the fuel line from the fuel rail;

release the retaining clip to detach the return

pipe from the pressure regulator. Plug the

exposed ends of the hoses and connections,

to prevent fuel spillage and the ingress of dirt.

Position the hoses out of the way.

10 Press the clamp ring inwards, and

simultaneously pull free the brake servo hose

from the inlet manifold. Position it out of the

way.

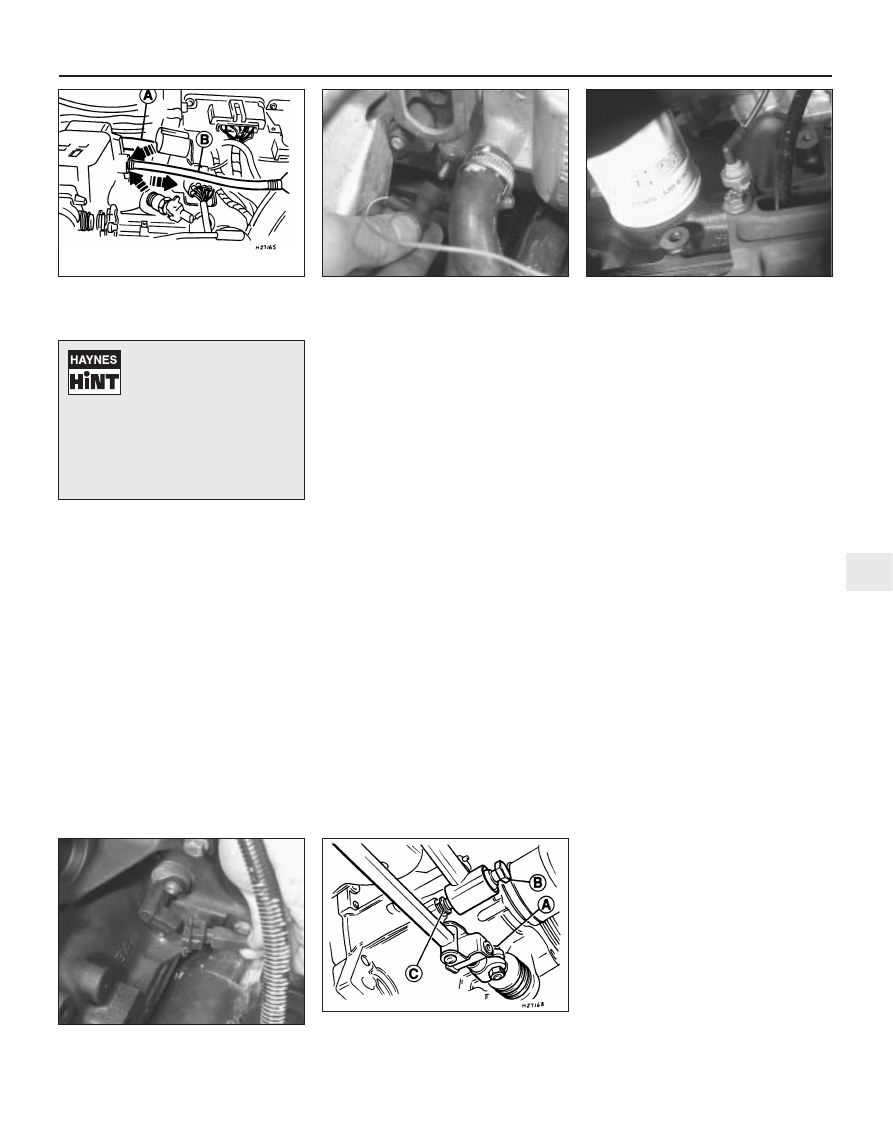

11 On CFi and EFi models, detach the

vacuum hose from the MAP sensor, and the

hose between the carbon canister and the fuel

injection unit (see illustration).

12 Note their connections and routings, and

detach the following wiring connections,

according to model (see illustrations):

a)

Coolant temperature sender unit.

b)

Oil pressure switch.

c)

E-DIS ignition coil unit. or distributor.

d)

Coolant temperature sensor.

e)

Cooling fan thermostatic switch.

f)

Carburettor.

g)

Earth lead (radio).

h)

Reversing light switch (from transmission).

i)

Crankshaft position sensor.

j)

Earth leads from the transmission and

engine.

13 Disconnect the wiring at the following

additional items specific to fuel injection

models only.

a)

Inlet air temperature sensor.

b)

Vehicle speed sensor.

c)

Throttle plate control motor (CFi

models).

d)

Throttle position sensor.

e)

Injector harness connector.

f)

Idle speed control valve (EFi and SEFi

models).

14 Unscrew the retaining bolt and detach the

bracket locating the wiring and coolant hoses

above the transmission.

15 Disconnect the speedometer drive cable

from the transmission.

16 On instruction transmission models,

disconnect the clutch cable from the release

lever at the transmission (see Chapter 6 for

details). Position the cable out of the way.

17 On vehicles fitted with the anti-lock

braking system, refer to Chapter 9 and release

the left-hand modulator from its mounting

bracket, without disconnecting the rigid brake

pipes or return hose. Tie the modulator

securely to the bulkhead.

18 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support”). Allow

sufficient clearance under the vehicle to

withdraw the engine and transmission units

from under the front end.

19 On XR2i models, refer to Chapter 10 and

remove the front suspension crossmember.

20 Where applicable on catalytic converter-

equipped vehicles, release the multi-plug from

the bracket and disconnect the wiring

connector from the oxygen sensor in the

exhaust downpipe.

21 Undo the three retaining bolts, detach the

exhaust downpipe from the manifold, and

collect the gasket from the flange joint. Now

disconnect the exhaust downpipe from the

rest of the system, and remove it from the

vehicle.

22 Where fitted, undo the four retaining nuts

and two bolts securing the front part of the

exhaust heat shield to the floor, then remove

the heat shield.

23 Refer to Chapter 5A and remove the

alternator and starter motor. On models with

power steering, refer to Chapter 10 and

remove the power steering pump.

Instruction transmission models

24 On 4-speed models, select 2nd gear; on

5-speed models, select 4th gear, to assist in

correct adjustment of the gearchange during

reassembly. If it is likely that the gear lever will

be moved from this position before refitting,

mark the relative position of the transmission

shift rod and the selector shaft before

separating them. Undo the clamp bolt, and

then pull free and detach the shift rod from the

selector shaft (see illustration).

Engine removal and overhaul procedures 2D•9

4.12b . . . the oil pressure switch . . .

4.12a Disconnect the wiring at the

temperature gauge sender unit . . .

4.11 Vacuum hose to MAP sensor (A) and

brake servo (B)

4.24 Instruction transmission shift rod clamp

bolt (A), stabiliser-to-transmission bolt (B)

and washer (C)

4.12c . . . and the crankshaft position

sensor

2D

1595Ford Fiesta Remake

Whenever you disconnect

any vacuum lines, coolant or

emissions hoses, wiring

connectors and fuel lines,

always label them clearly, so that they

can be correctly reassembled. Masking

tape and/or a touch-up paint applicator

work well for marking items. Take

instant photos, or sketch the locations

of components and brackets.