Bobcat S150. Manual - part 11

S150 Bobcat Loader

27

Operation & Maintenance Manual

STARTING THE ENGINE (DELUXE PANEL, KEYLESS

START (CONT’D)

Procedure (Cont’d)

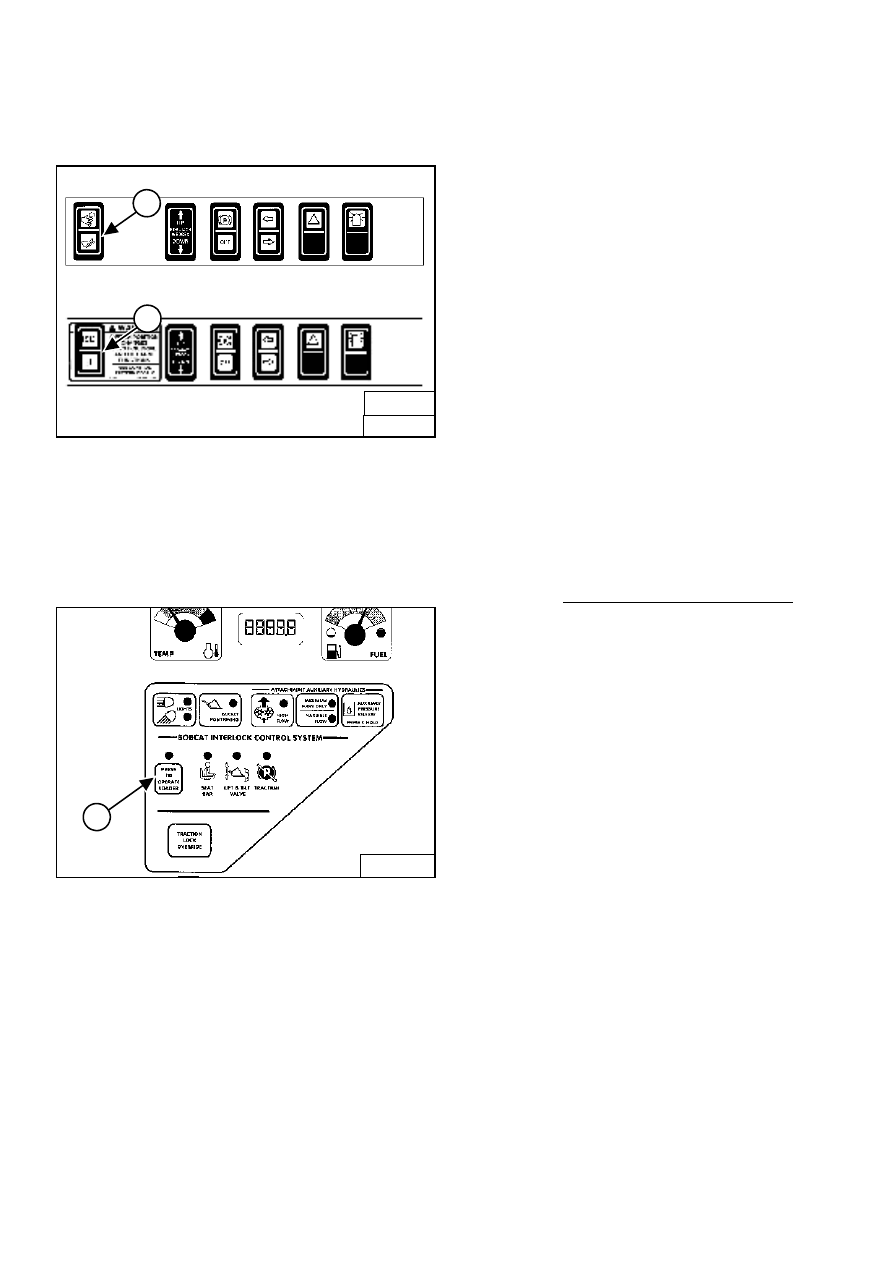

Figure 55

(ACS) Select hand control or foot pedal operation (1)

[Figure 55].

OR

(SJC) Select ‘ISO’ or ‘H’ Control Pattern (2) [Figure 55].

Figure 56

Press the PRESS TO OPERATE LOADER Button (1)

[Figure 56] to activate the BICS system and to perform

hydraulic and loader functions. (See Cold Temperature

Starting on Page 27.)

NOTE: (SJC) The pending mode will flash which will

indicate PRESS TO OPERATE LOADER is

required. The light will flash when key is ON

and continue to flash until the PRESS TO

OPERATE LOADER button is pressed and

thereafter it will light solid. If the mode (ISO/H)

is changed while driving, the active mode will

be solid and the pending mode will flash.

When operation of the machine is returned to

neutral, the active mode will then turn off and

the pending mode will continue to flash until

the PRESS TO OPERATE LOADER button is

pressed.

Cold Temperature Starting

If the temperature is below freezing, perform the following

to make starting the engine easier:

•

Replace the engine oil with the correct type and

viscosity for the anticipated starting temperature.

(See also ENGINE LUBRICATION SYSTEM on

Page 67.)

•

Make sure the battery is fully charged.

•

Install an engine heater, available from your Bobcat

loader dealer.

NOTE: The display screen of the Deluxe Panel may

not be immediately visible when the

temperature is below -26° C (-15 ° F). It may

take 30 seconds to several minutes for the

Display Panel to warm up. All systems remain

monitored even when the display is off.

B-15993B

SJC

2

B-15993H

FRONT ACCESSORY PANEL

ACS

1

B-15551

1