Bobcat S150. Manual - part 9

S150 Bobcat Loader

19

Operation & Maintenance Manual

HYDRAULIC CONTROLS (CONT’D)

FRONT Auxiliary Hydraulics Operation - VARIABLE

FLOW

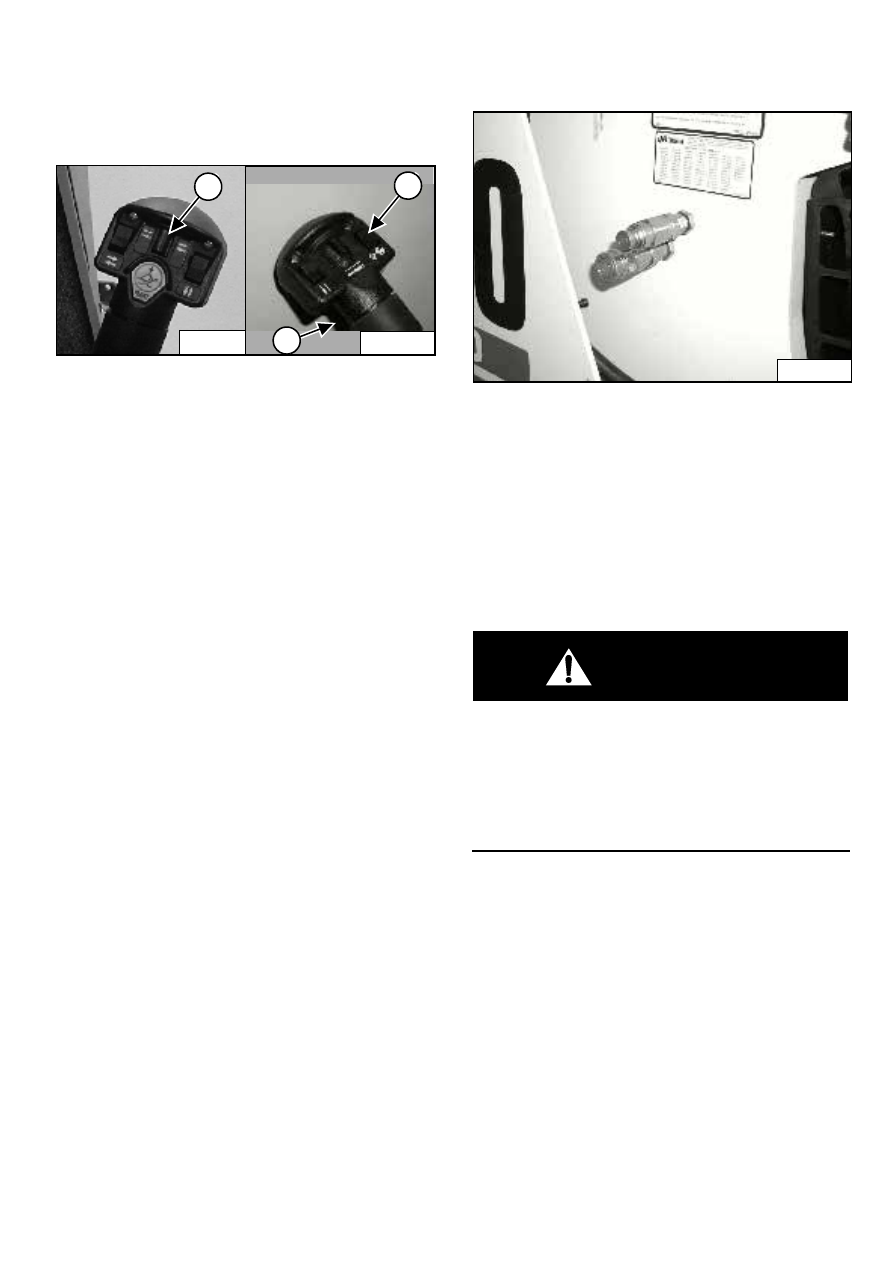

Figure 39

Press the auxiliary hydraulics button for VARIABLE

FLOW (See also Auxiliary Hydraulics Button - VARIABLE

FLOW on Page 18).

Push the switch (1) [Figure 39] to the right or left to

change the fluid flow direction of the front quick couplers.

(EXAMPLE: Open and close grapple teeth.)

FRONT Auxiliary Hydraulics Operation - MAXIMUM

FLOW

Press the auxiliary hydraulics button for MAXIMUM

FLOW.

Push the switch (1) [Figure 39] to the right or left to

change the fluid flow direction of the front quick couplers.

(EXAMPLE: Open and close grapple teeth.)

FRONT Auxiliary Hydraulics Operation -

CONTINUOUS FLOW

After selecting VARIABLE or MAXIMUM FLOW, press

the front switch (2) [Figure 39] to give the front quick

couplers a constant flow of fluid with the female coupler

being pressurized. (EXAMPLE: Operate a backhoe.)

REVERSE CONTINUOUS FLOW - To set reverse flow

(male coupler pressurized), select VARIABLE or

MAXIMUM FLOW, then, while holding the auxiliary

switch (1) [Figure 39] to the left, press the front

switch (2) [Figure 39]. Reverse flow can be used only

with augers, power rakes, sweepers, tillers, and vibratory

rollers.

To release from continuous operation, press the front

switch (2) [Figure 39] a second time.

REAR Auxiliary Hydraulics Operation (If Equipped)

Figure 40

The switches on the left hand lever control the rear

auxiliary hydraulics.

Press the auxiliary hydraulics button for MAXIMUM

FLOW (See also Auxiliary Hydraulics Button - MAXIMUM

FLOW ONLY on Page 18).

Push the switch (3) [Figure 39] to the right or left to

change the fluid flow direction to rear quick couplers

[Figure 40]. (EXAMPLE: Raise and lower rear

stabilizers.)

WARNING

Diesel fuel or hydraulic fluid under pressure can

penetrate skin or eyes, causing serious injury or

death. Fluid leaks under pressure may not be visible.

Use a piece of cardboard or wood to find leaks. Do

not use your bare hand. Wear safety goggles. If fluid

enters skin or eyes, get immediate medical attention

from a physician familiar with this injury.

W-2007-0497

P-31833

2

1

3

P-16537

P-48004