Loader Bobcat 773. Manual - part 77

STARTER (DENSO) (Cont’d)

Disassembly (Cont’d)

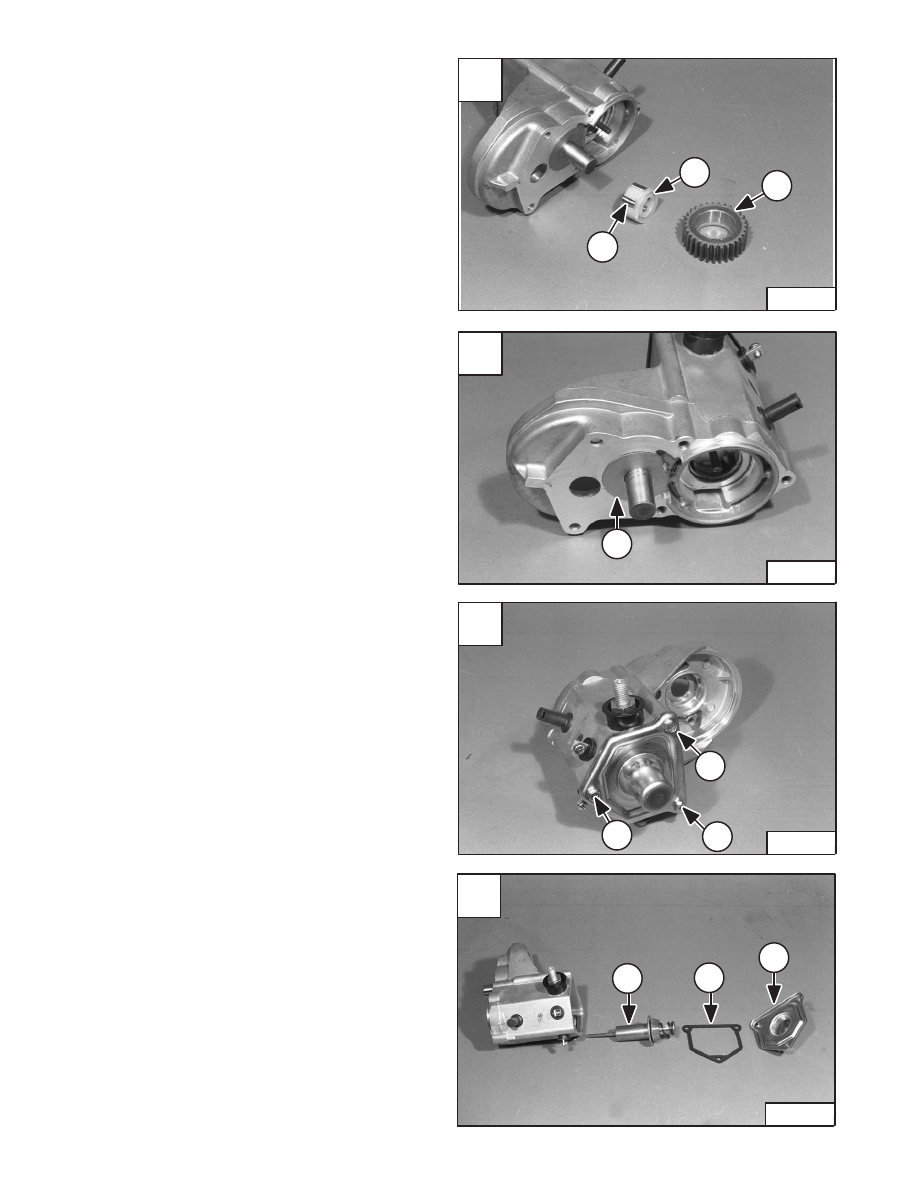

Remove the idler gear (Item 1) [A], retainer (Item 2) [A]

and rollers (Item 3) [A] from the magnetic switch housing.

Remove the washer (Item 1) [B] from the idler gear shaft.

Remove the bolts (Item 1) [C] from the magnetic switch.

Remove the cover (Item 1) [D], gasket (Item 2) [D] and

switch (Item 3) [D].

A

N–15168

2

3

1

C

N–15150

1

1

1

D

N–15151

3

2

1

–6–24–

773 BICS Loader

Service Manual

B

N–15169

1