Volkswagen Fox (2004 year). Manual - part 55

Sequence Wheel brake cyl‐

inder brake shoes

Amount of brake fluid that must be

drained from the wheel brake cyl‐

inders, that is, from the brake fit‐

tings:

right rear

0.25 litre

left rear

0.25 litre

right front

0.25 litre

left front

0.25 litre

Total quantity: 1 litre

15) of brake fluid drained from the brake fluid reservoir and from quantity changed

in the hydraulic clutch drive.

– Put the protection covers in the bleeding screws.

– Change the position of the passage lever on the Brake filler

and bleeder -VAS 5234- or on the Brake bleeding device -VAG

1869- to position -B- (check the operating instructions).

– Remove the passage hose from the adapter.

– Remove the brake fluid reservoir adaptor.

– Install the brake fluid reservoir cover.

– Remove the Brake pedal's tensioning element -VAG 1869/2-

between the driver's seat and the brake pedal, by pressing it.

– Check the brake pedal's pressure and its free clearance. Max.

clearance 1/3 of the pedal stroke.

WARNING

Do not forget to always correct the brake fluid's level in the

reservoir.

Never let it reach the minimum level, otherwise air may enter

the system.

Do not reuse the (used) aspirated brake fluid!

4.40

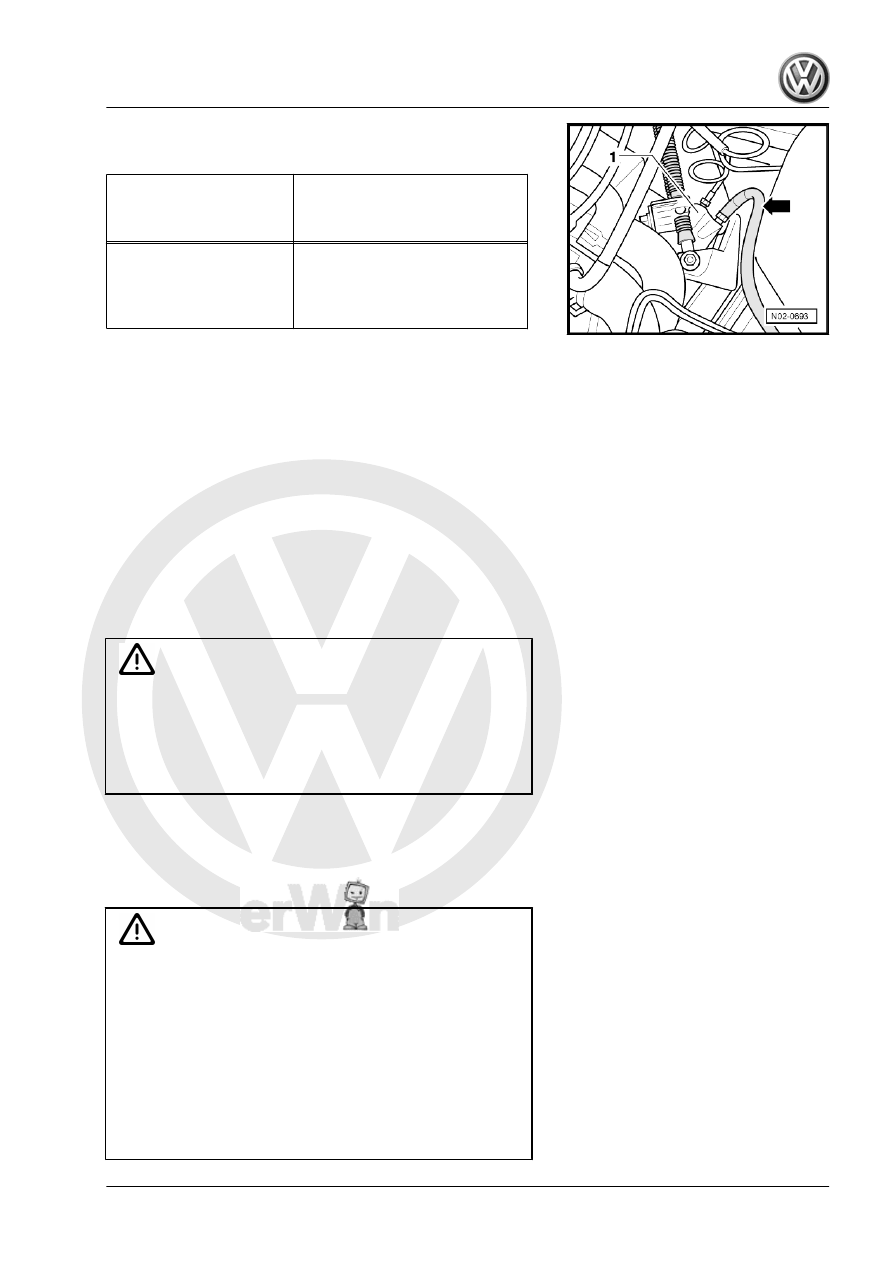

Brake fluid level (depending on brake

pad/lining wear) - check

Use only new, original VW brake fluid.

WARNING

♦ Do not let the brake fluid contact fluids containing mineral

oils (oil, petrol, cleaning products). Mineral oils damage

the seals and brake system hoses.

♦ The brake fluid is toxic. Additionally, due to its corrosive

effect, it must not come into contact with painted surfaces.

♦ The brake fluid is hygroscopic, that is, it absorbs the local

air humidity and, for this reason, it is stored in airtight

packages.

♦ Wash off any brake fluid spillage with plenty of water.

♦ Follow the rules for disposal!

FOX 2004 ➤

4. Service descriptions

93