Toyota RM06H0E engine. Manual - part 6

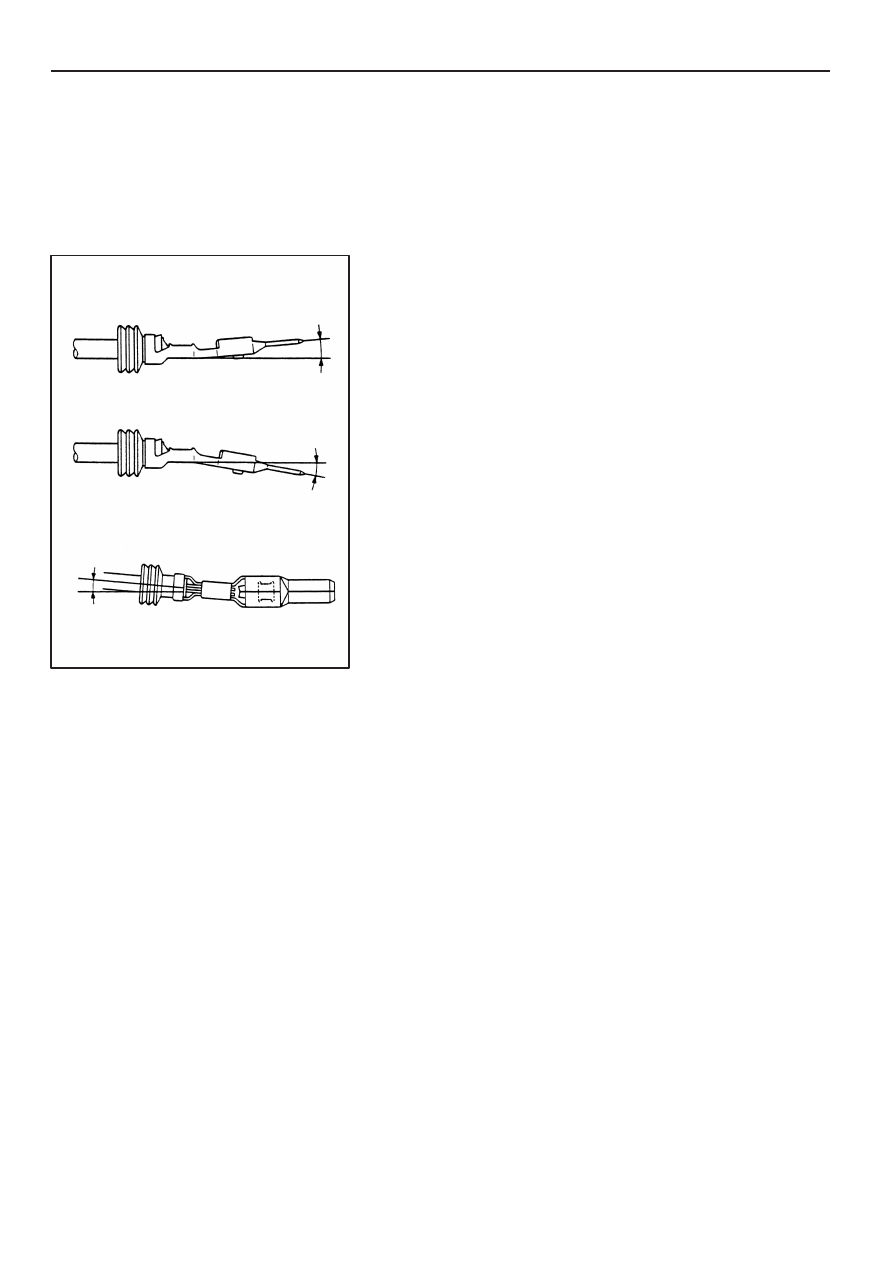

Terminal Deformation

(1)

Terminal Bending in Vertical Direction

(2)

Terminal Bending in Horizontal Direction

1

°

or less

1

°

or less

3°

or less

B–29

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

45

Wire Harness Repair Manual

(b)

Remove the insulation displacement female terminal

NOTICE:

D

Do not repair the insulation displacement female

terminal.

D

Always replace the part with a new one if any

terminals are removed.

5.

Inspect the terminal and the connector for

damage.

NOTE:

D

The locking clip is easily damaged.

D

Do not reuse the damaged part.