Toyota RM06H0E engine. Manual - part 5

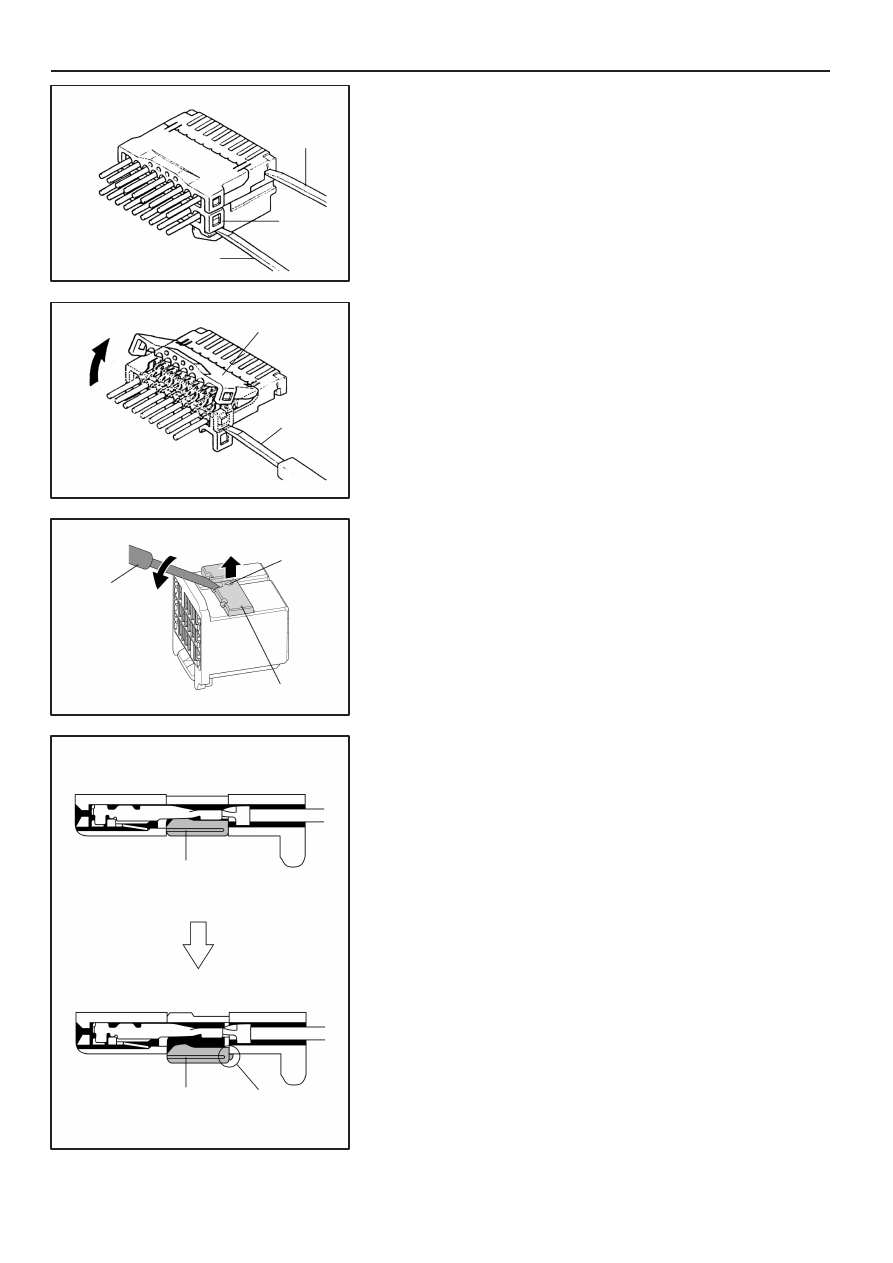

Special Tool

Lock

Special Tool

Cover

Special Tool

Raise Up

Special Tool

Special Tool

Insert Mark

Terminal

Retainer

Terminal Retainer

[Retainer at Full Lock Position]

Stopper

[Retainer at Temporary Lock Position]

Terminal

Retainer

B–21

TERMINAL AND CONNECTOR REPAIR–TERMINAL REPLACEMENT

37

Wire Harness Repair Manual

Type K (For Insulation Displacement Connector)

(1)

Separate Connector

Using a special tool, release the lock and separate the

connector into 2.

NOTICE:

Do not apply too muck force to the lock arm.

(2)

w/ Cover : Open Connector Cover

Using a special tool, release the lock and open the cover.

NOTICE:

Do not apply too much force to the lock arm.

Type L (For 0.64 Type Connector)

(1)

Using the special tool, raise the retainer up to the

temporary lock position.

HINT:

The needle insertion position varies according to

the connector’s shape (number of terminals, etc.), so

check the position before inserting it.