4A–FE engine is an in–line, 4–cylinder, 1.6 liter DOHC 16–valve engine. Manual - part 32

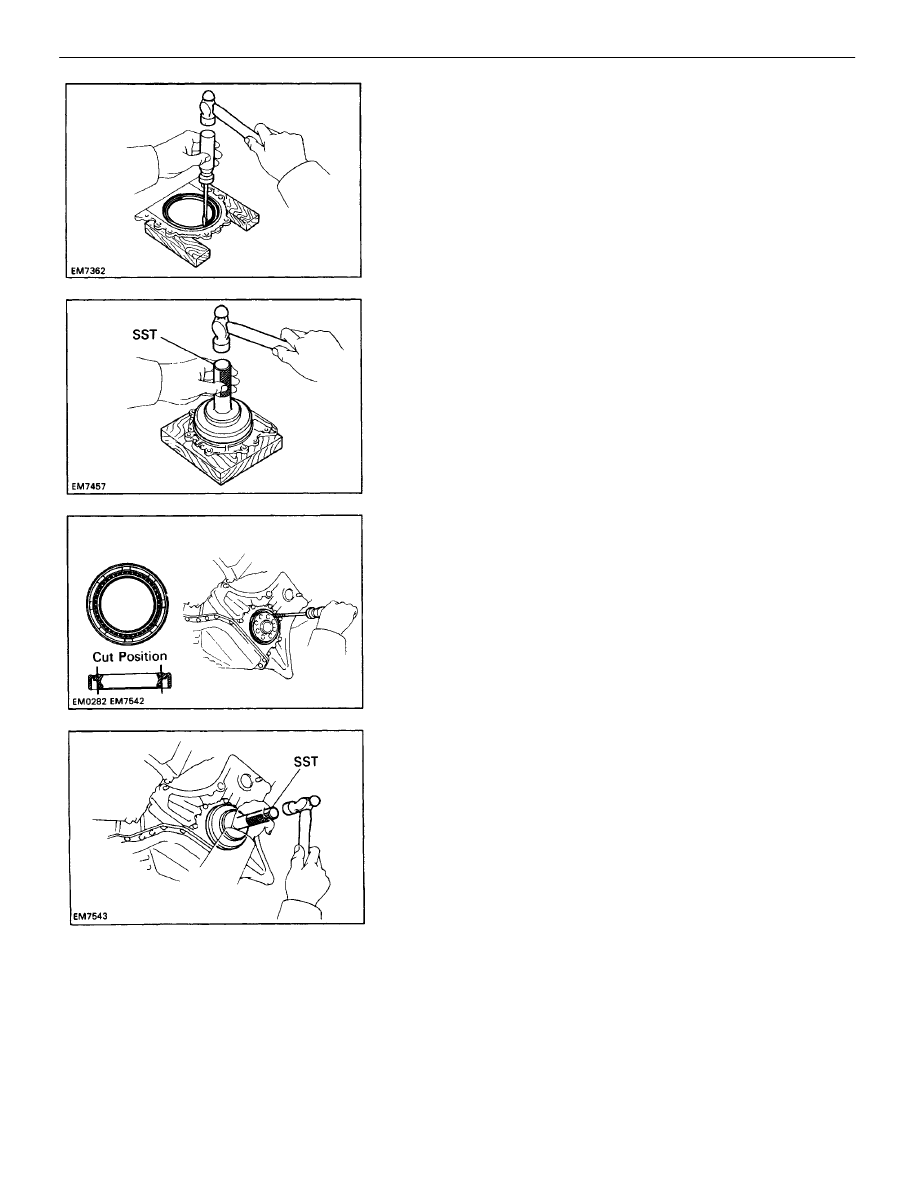

B. If rear oil seal retainer is installed to cylinder block:

(a) Using a knife, cut off the oil seal lip.

(b) Using a screwdriver, pry out the oil seal.

NOTICE: Be careful not to damage the crankshaft.

Tape the screwdriver tip.

(b) Using SST and a hammer, tap in a new oil seal

until its surface is flush with the rear oil seal

edge.

SST 09223–63010

(c) Apply MP grease to the oil seal lip.

(c) Apply M P grease to a new oil seal lip.

(d) Using SST and a hammer, tap in the oil seal until

its surface is flush with the rear oil seal retainer

edge.

SST 09223–63010

2. REPLACE CRANKSHAFT REAR OIL SEAL

A. If rear oil seal retainer is removed from cylinder block:

(a) Using screwdriver and hammer, tap out the oil seal.

–

ENGINE MECHANICAL

Cylinder Block (3S–GTE)

EM–250