Toyota Automatic Transmission A340 Series. Repair Manual - part 7

AT1636

AT8225

AT8236

AT8334

SST

(i)

Insert SST behind No. 1 brake piston and gradu-

ally lift it out of the transmission case.

SST

09350−30020 (09350−07090)

(j)

Remove the two O−rings from No. 1 piston.

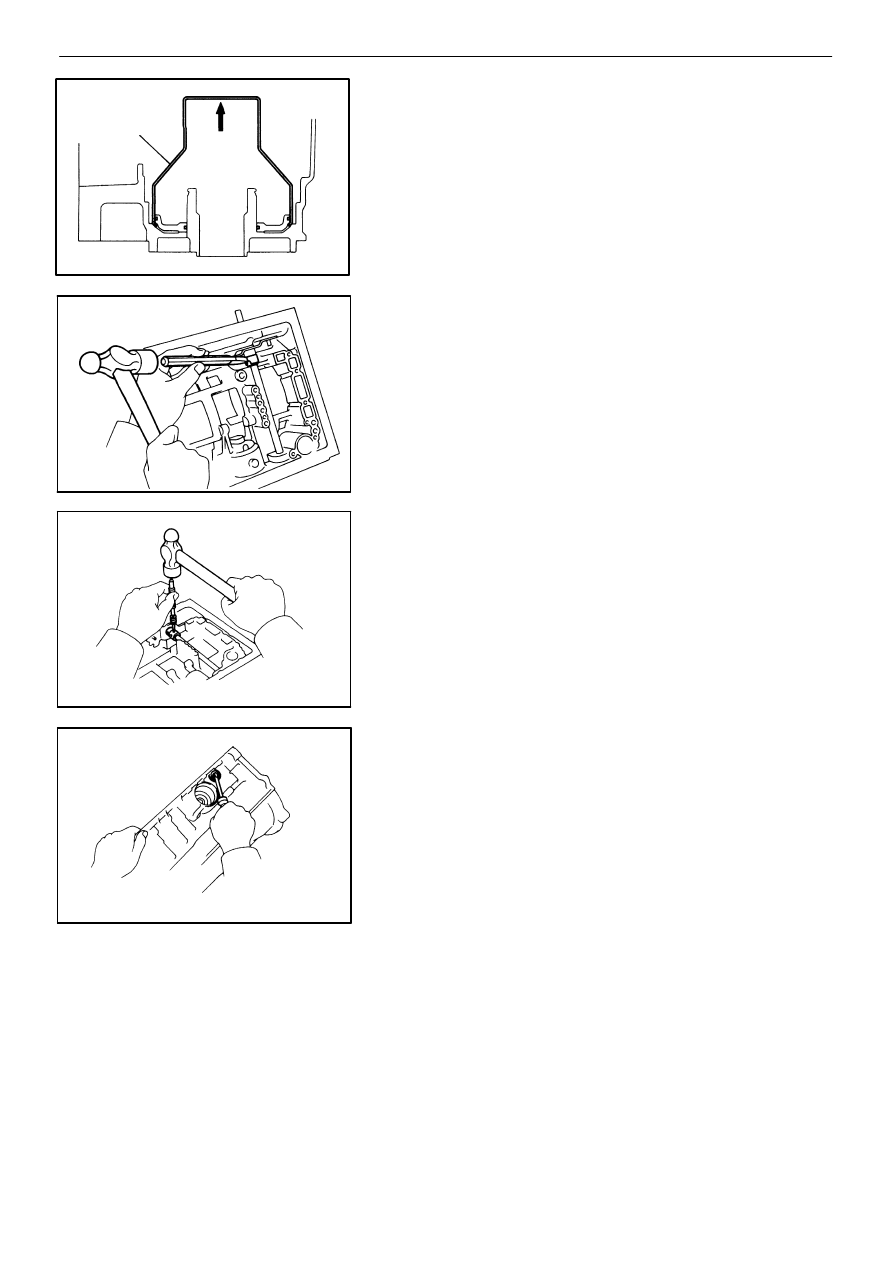

40. REMOVE MANUAL VALVE LEVER, SHAFT AND OIL

SEALS

(a)

Using a chisel, cut off the spacer and remove it

from the shaft.

(b)

Using a pin punch, drive out the pin.

(c)

Pull the manual valve lever shaft out through the

case and remove the lever.

(d)

Using a screwdriver, remove the two oil seals.

AT−45

−

AUTOMATIC TRANSMISSION (A340E)

Removal of Component Parts