Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 326

ME–36

METER – METER / GAUGE SYSTEM

ME

4.

INSPECT FUEL RECEIVER GAUGE

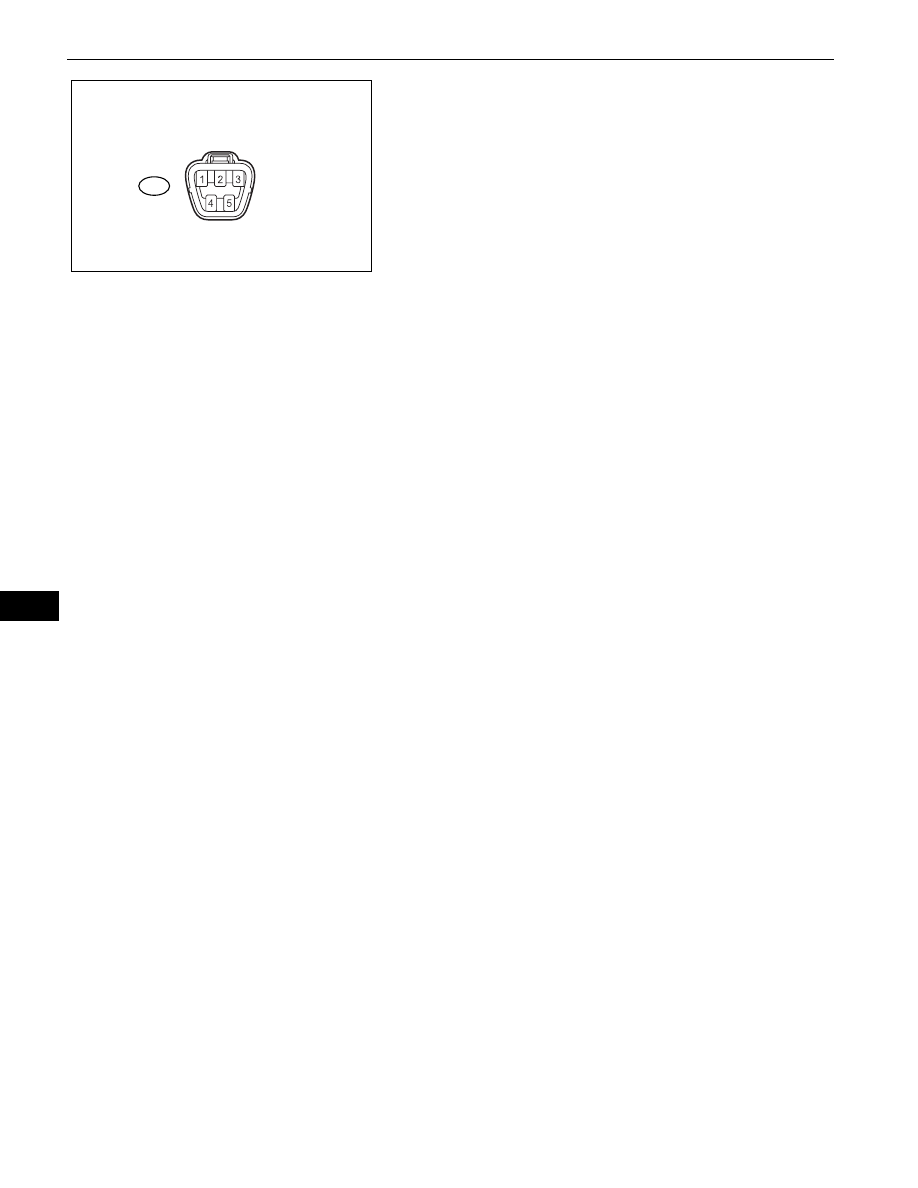

(a) Disconnect the L5 fuel sender gauge connector.

(b) Check the fuel receiver gauge operation when the

ignition switch is turned to the ON position.

OK:

Needle position is on EMPTY.

(c) Connect terminals 2 and 3 on the wire harness side

connector of the fuel sender gauge.

(d) Check the fuel receiver gauge operation when the

ignition switch is turned from OFF to ON.

OK:

Needle position is on FULL.

(e) Reconnect the fuel sender gauge connector.

5.

INSPECT FUEL LEVEL WARNING LIGHT

(a) Disconnect the fuel sender gauge connector.

(b) Turn the ignition switch to the ON position, then

check that the fuel level needle indicates EMPTY

and the fuel level warning light comes on.

OK:

Fuel level warning light comes on.

(c) Reconnect the fuel sender gauge connector.

6.

INSPECT ENGINE OIL PRESSURE WARNING LIGHT

(a) Disconnect the engine oil pressure switch

connector.

(b) Turn the ignition switch to the ON position.

(c) Ground the terminal of the wire harness side

connector, then check the engine oil pressure

warning light.

OK:

Engine oil pressure warning light illuminates.

(d) Reconnect the engine oil pressure switch connector.

7.

INSPECT BRAKE WARNING LIGHT

(a) Inspect the parking brake warning light.

(1) Disconnect the parking brake switch connector.

(2) Turn the ignition switch to the ON position.

(3) Ground the terminal of the wire harness side

connector, then check the parking brake

warning light.

OK:

Brake warning light illuminates.

(4) Reconnect the parking brake switch connector.

(b) Inspect the brake fluid level warning light.

(1) Disconnect the brake fluid level warning switch

connector.

(2) Turn the ignition switch to the ON position.

(3) Connect a terminal to the other terminal of the

wire harness side connector, then check the

brake fluid level warning switch.

OK:

Brake warning light illuminates.

(4) Reconnect the brake fluid level warning switch

connector.

Wire Harness Side:

Front View

Fuel Sender Gauge Connector

L5

E126857E01