Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 164

1GR-FE ENGINE MECHANICAL – CYLINDER HEAD

EM–89

EM

INSTALLATION

1.

INSTALL NO. 2 CYLINDER HEAD GASKET

(a) Remove any old packing (FIPG) material.

HINT:

Do not drop any oil on the contact surface of the

cylinder head and cylinder block.

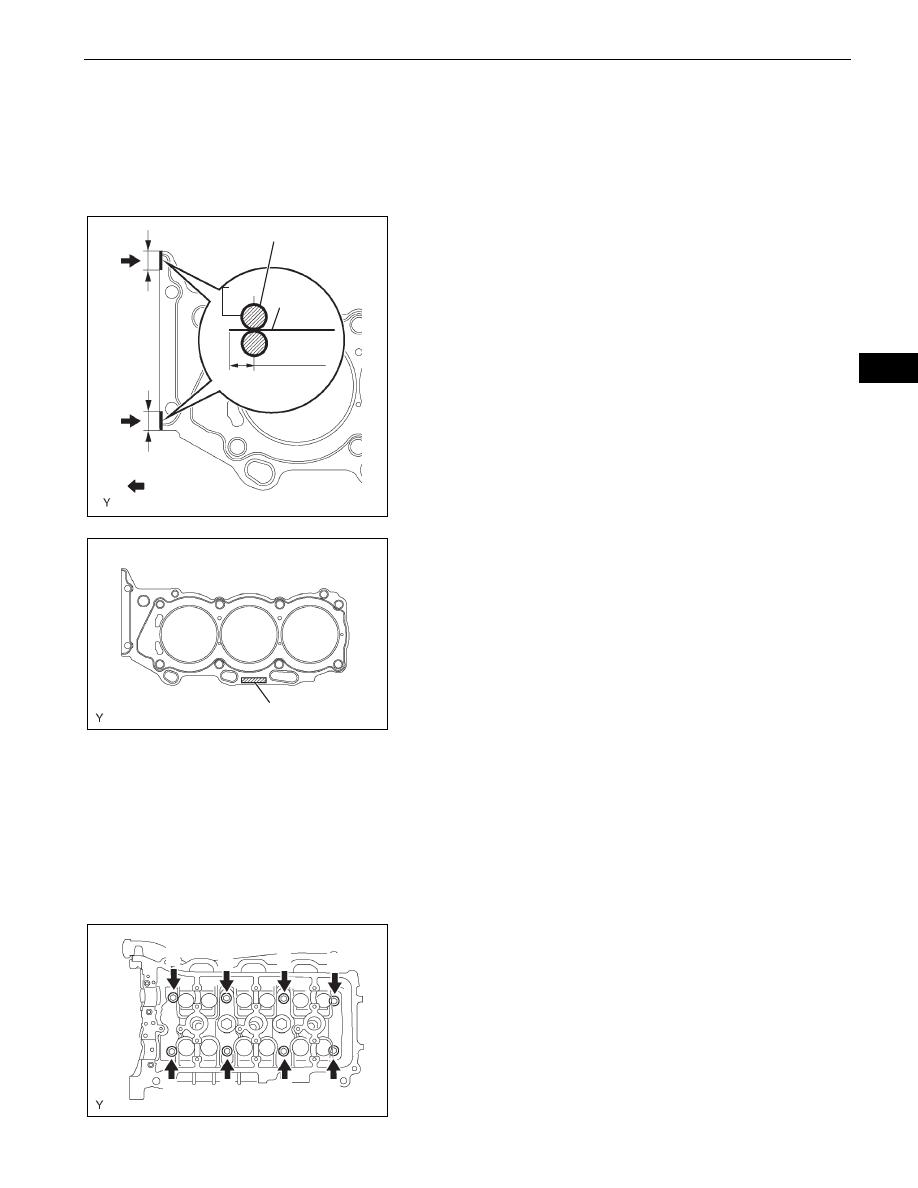

(b) Apply a continuous bead of seal packing (diameter

2.5 to 3.0 mm (0.098 to 0.118 in.)) to a new cylinder

head gasket as shown in the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three

Bond 1207B or the equivalent

NOTICE:

Install the cylinder head within 3 minutes of

applying the seal packing. Tighten the cylinder

head bolts within 15 minutes of installing the

cylinder head. Otherwise, the seal packing must

be removed and reapplied.

(c) Place the cylinder head gasket on the cylinder block

surface with the Lot No. stamp facing upward.

NOTICE:

•

Orient the cylinder head gasket correctly.

•

Place the cylinder head carefully in order not

to damage the gasket with the bottom part of

the head.

2.

INSTALL CYLINDER HEAD LH

(a) Place the cylinder head on the cylinder head gasket.

(b) Install the 8 cylinder head bolts.

HINT:

•

The cylinder head bolts are tightened in 2

successive steps (steps (*1) and (*2)).

•

If any cylinder head bolts are broken or

deformed, replace them.

(1) Apply a light coat of engine oil to the threads of

the cylinder head bolts.

(2) Install the plate washer onto the cylinder head

bolt.

(3) Using several steps, uniformly tighten each bolt

with a 10 mm bi-hexagon wrench in the

sequence shown in the illustration. (*1)

Torque: 36 N*m (367 kgf*cm, 27 ft.*lbf)

If any cylinder head bolts do not meet the

torque specification, replace them.

NOTICE:

Do not drop the washers into the cylinder

head.

10 to 15 mm

10 to 15 mm

Seal Packing

1.25 to 1.5 mm

Gasket

Ǿ 2.5 to 3 mm

A076275E02

Lot No.

A076276E02

1

5

6

4

7

8

3

2

A076277E01