Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 125

ES–448

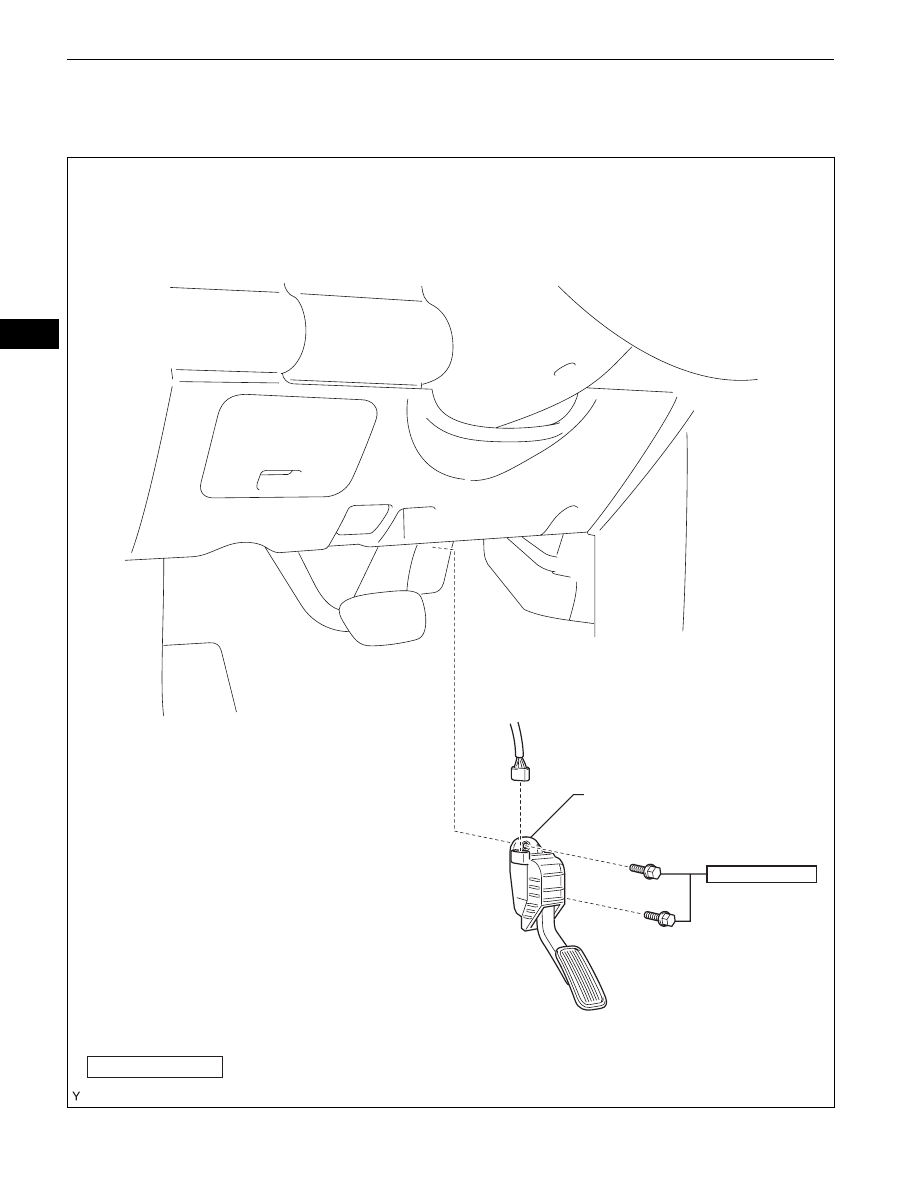

1GR-FE ENGINE CONTROL SYSTEM – ACCELERATOR PEDAL

ES

ENGINE

1GR-FE ENGINE CONTROL SYSTEM

ACCELERATOR PEDAL

COMPONENTS

ACCELERATOR PEDAL ROD

ASSEMBLY

N*m (kgf*cm, ft*lbf) : Specified torque

5.0 (51, 44 in.*lbf)

A126414E01