Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 123

ES–440

1GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSOR

ES

2.

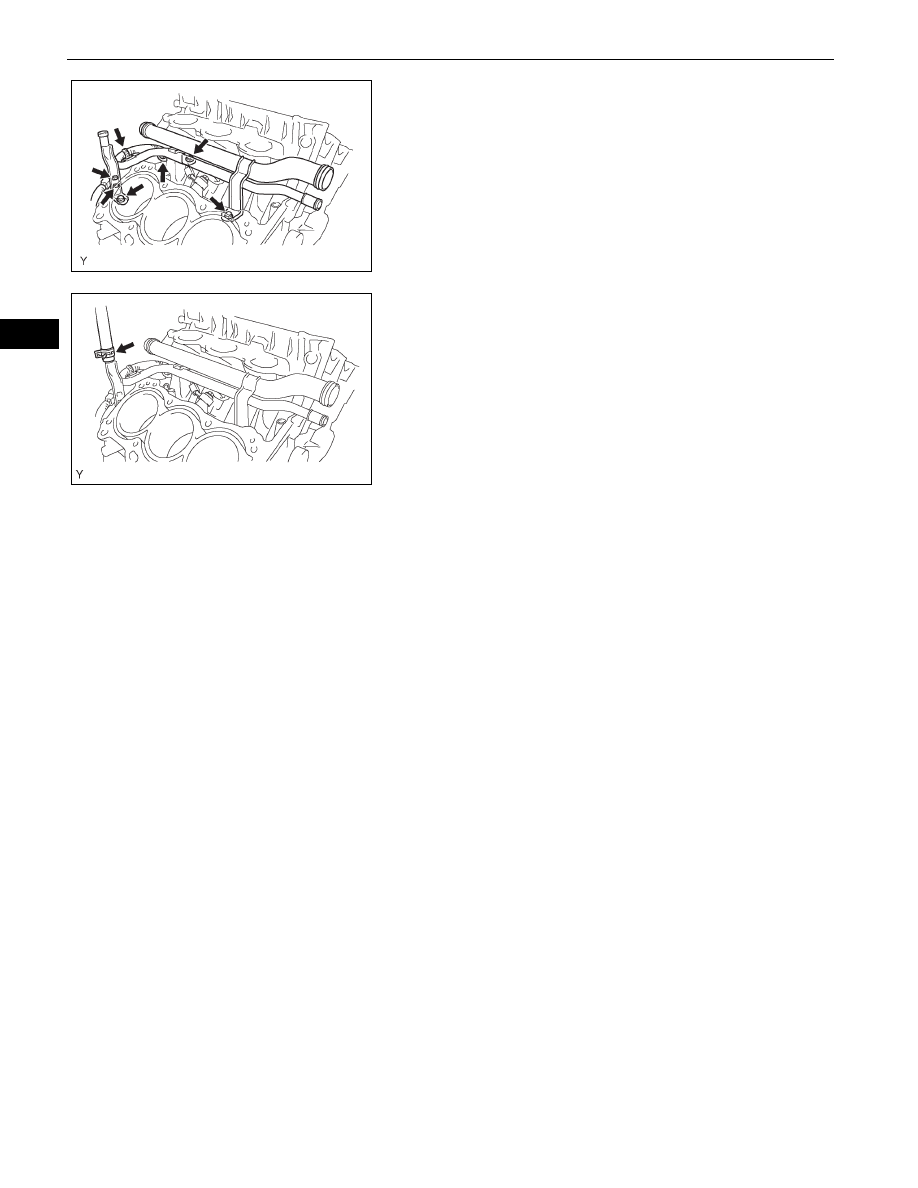

INSTALL NO. 1 WATER OUTLET PIPE

(a) Install the water outlet pipe with the 3 bolts.

Torque: 10 N*m (102 kgf*cm, 7.4 ft.*lbf)

(b) Install the 4 wire harness clamps.

3.

CONNECT HEATER WATER INLET HOSE

(a) Connect the heater water inlet hose to the water

outlet pipe.

4.

INSPECT CYLINDER HEAD SET BOLT (See page

)

5.

INSTALL CYLINDER HEAD GASKET (See page

)

6.

INSTALL CYLINDER HEAD SUB-ASSEMBLY (See

page

)

7.

INSTALL NO. 2 CAMSHAFT BEARING (See page

)

8.

INSTALL CAMSHAFTS (for Bank 1) (See page

9.

INSTALL NO. 2 CHAIN TENSIONER ASSEMBLY (See

page

)

10. INSTALL CAMSHAFT TIMING GEARS AND NO. 2

CHAIN (for Bank 1) (See page

)

11. INSTALL WATER BY-PASS JOINT RR (See page

)

12. INSTALL INTAKE MANIFOLD (See page

13. CONNECT NO. 2 FUEL PIPE SUB-ASSEMBLY (See

page

)

14. CONNECT NO. 1 FUEL PIPE SUB-ASSEMBLY (See

page

)

15. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH

(See page

)

16. INSTALL MANIFOLD STAY (See page

17. INSTALL FRONT EXHAUST PIPE ASSEMBLY (See

page

)

18. INSTALL NO. 2 FRONT EXHAUST PIPE ASSEMBLY

(See page

)

19. INSTALL EXHAUST PIPE STOPPER BRACKET (for

4WD)

20. INSTALL NO. 1 COOL AIR INLET (See page

)

G036164E01

A076171E01