Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 117

1GR-FE ENGINE CONTROL SYSTEM – VVT SENSOR

ES–417

ES

REMOVAL

1.

DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

2.

DRAIN ENGINE COOLANT (See page

)

3.

REMOVE V-BANK COVER (See page

)

4.

REMOVE AIR CLEANER ASSEMBLY (See page

)

5.

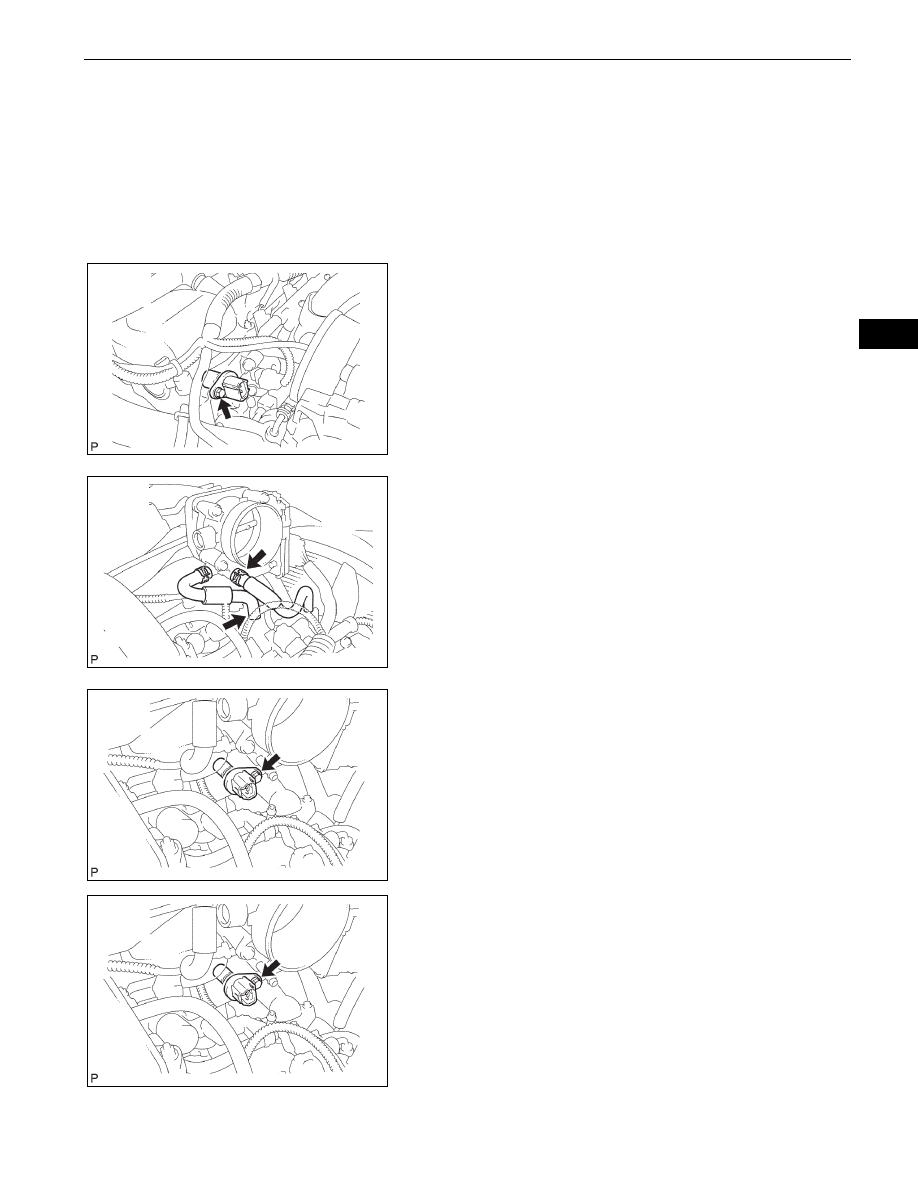

REMOVE VVT SENSOR

(a) Bank 1 side VVT sensor:

(1) Disconnect the VVT sensor connector.

(2) Remove the bolt and VVT sensor.

(b) Bank 2 side VVT sensor:

(1) Disconnect the No. 4 water by-pass hose and

No. 5 water by-pass hose.

(2) Disconnect the VVT sensor connector.

(3) Remove the bolt and VVT sensor.

INSTALLATION

1.

INSTALL VVT SENSOR

(a) Bank 2 side VVT sensor:

(1) Apply a light coat of engine oil to the O-ring of

the VVT sensor.

(2) Install the VVT sensor with the bolt.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

Bank 1:

A076413E02

Bank 2:

A076414E02

Bank 2:

A076415E02

Bank 2:

A076415E02