содержание .. 676 677 678 679 ..

Toyota Sequoia (2005). Manual - part 678

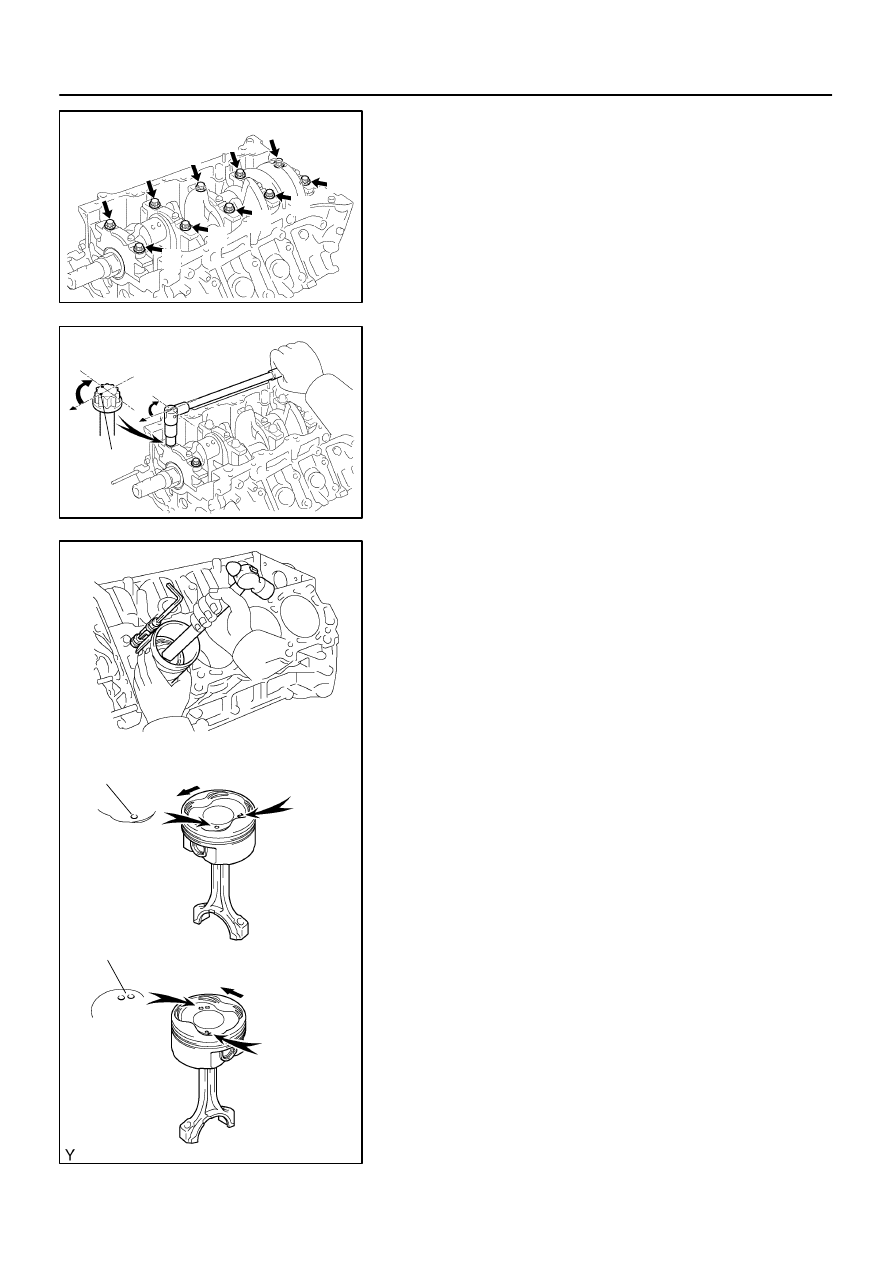

A05095

1

2

4

8

6

3

5

9

7

10

A05094

Front

Painted

Mark

90

°

90

°

A23371

Front Mark

(1 Cavity)

Front

LH

Piston

RH

Piston

Front

Front Mark

(2 Cavities)

EM–122

–

ENGINE MECHANICAL

CYLINDER BLOCK

2701

(a)

Apply a light coat of engine oil to the threads and under

the main bearing cap bolts.

(b)

Install and uniformly tighten the 10 main bearing cap bolts

in several steps, in the sequence shown.

Torque: 27 N·m (275 kgf·cm, 20 ft·lbf)

If any of the main bearing cap bolts does not meet the torque

specification, replace the main bearing cap bolt.

(c)

Mark the front of the main bearing cap bolt with paint.

(d)

Retighten the main bearing cap bolts by 90

°

in the numer-

ical order shown.

(e)

Check that the painted mark is now at a 90

°

angle to the

front.

(f)

Check that the crankshaft turns smoothly.

9.

CHECK CRANKSHAFT THRUST CLEARANCE

(See page

)

10.

INSTALL PISTON AND CONNECTING ROD AS-

SEMBLIES

Using a piston ring compressor, push correctly the numbered

piston and connecting rod assemblies into each cylinder with

the front mark of the piston facing forward.

NOTICE:

The shape of the piston differs for the LH and RH banks.

The LH piston is marked with 1 cavity and ”2”, the RH pis-

ton with 2 cavities and ”2”.