содержание .. 430 431 432 433 ..

Toyota Sequoia (2005). Manual - part 432

I28701

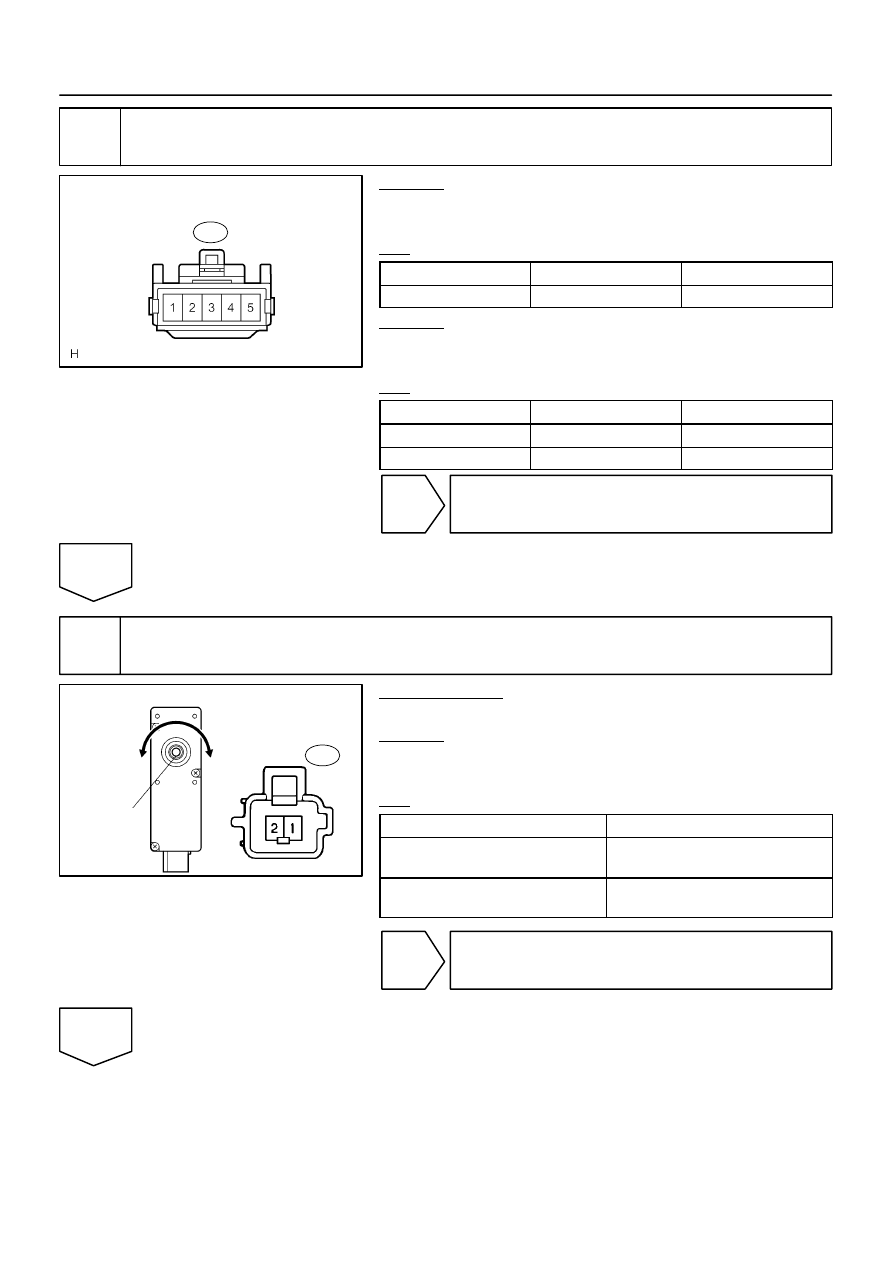

Wire Harness Side:

Lumbar Support Control Switch

L4

I28702

Lumbar Support Control Motor

Clockwise

Counter-

clockwise

Driving Axis

L3

–

DIAGNOSTICS

POWER SEAT CONTROL SYSTEM (w/ Driving Position

Memory)

DI–1523

1717

3

Check harness and connector (Power source).

CHECK:

Measure the voltage of each terminal of the wire harness side

connectors.

OK:

Tester Connection

Condition

Specified Condition

L4–3 – Body ground

Always

10 to 14 V

CHECK:

Measure the resistance of each terminal, as shown in the il-

lustration and table.

OK:

Tester Connection

Condition

Specified Condition

L4–2 – Body ground

Always

Below 1

Ω

L4–5 – Body ground

Always

Below 1

Ω

NG

Repair or replace harness or connector.

OK

4

Inspect lumbar support control motor.

PREPARATION:

Remove the lumbar support control motor (See page

CHECK:

Check that the motor rotates smoothly when the battery is con-

nected to the lumbar support control motor connector terminals.

OK:

Measurement Condition

Operational Direction

Battery positive (+)

→

1

Battery negative (–)

→

2

Clockwise

Battery positive (+)

→

2

Battery negative (–)

→

1

Counterclockwise

NG

Replace lumbar support control motor

(See page

OK