содержание .. 89 90 91 92 ..

Toyota Sequoia (2005). Manual - part 91

B17394

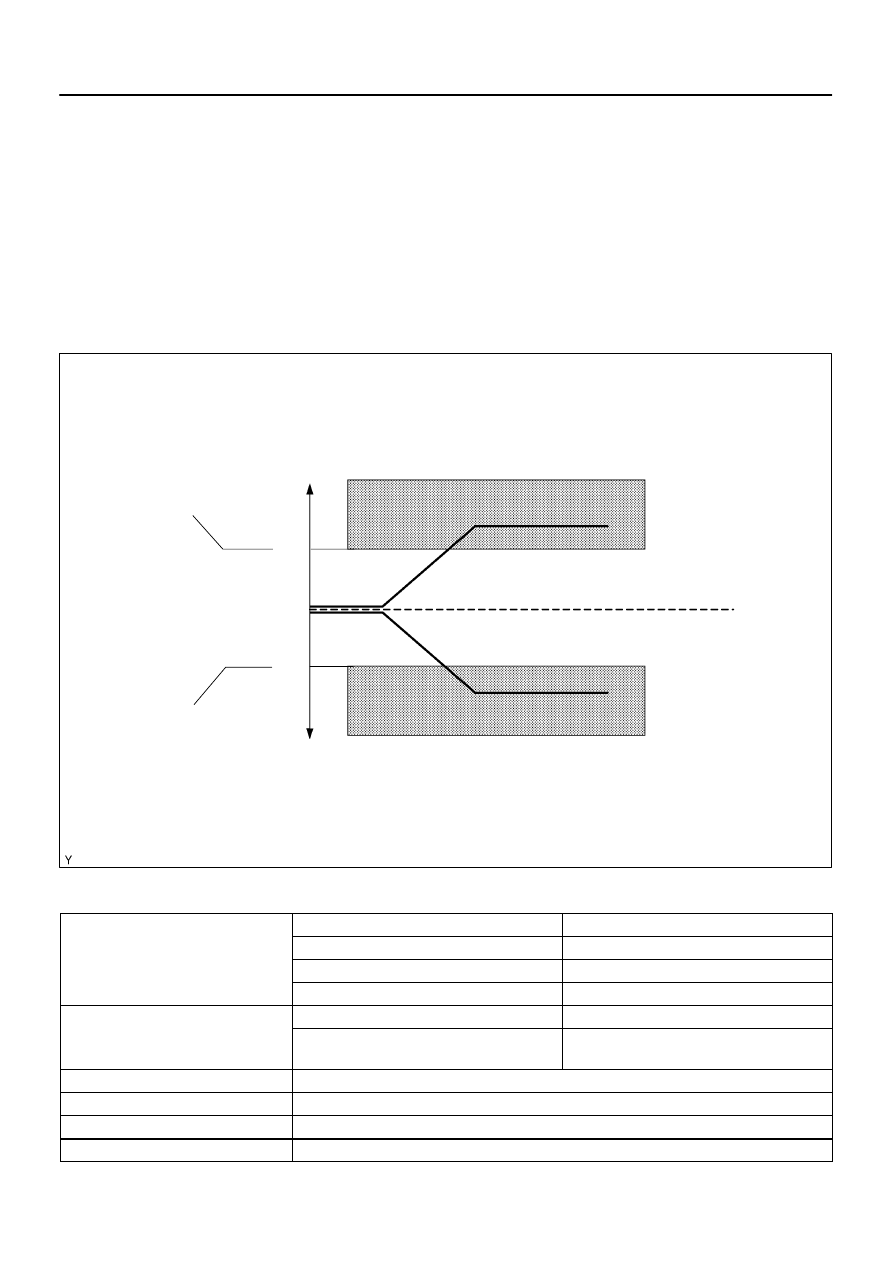

Fuel

Compensation

Amount

1.35

1.0

0.65

+35 (%):

Lean Malfunction Threshold

–35 (%):

Rich Malfunction Threshold

P0171, P0174:

P0172, P0175:

–

DIAGNOSTICS

ENGINE

DI–167

361

MONITOR DESCRIPTION

Under closed–loop fuel control, fuel injection volumes that deviate from those estimated by the ECM cause

changes in the long–term fuel trim compensation value. The long–term fuel trim is adjusted when there are

persistent deviations in the short–term fuel trim values. Deviations from the ECM’s estimated fuel injection

volumes also affect the average fuel trim learning value, which is a combination of the average short–term

fuel trim (fuel feedback compensation value) and the average long–term fuel trim (learning value of the air–

fuel ratio). If the average fuel trim learning value exceeds the malfunction thresholds, the ECM interprets

this a fault in the fuel system and sets a DTC.

Example:

The average fuel trim leaning value is more than +35 % or less than –35 %, the ECM interprets this as a fuel

system malfunction.

MONITOR STRATEGY

P0171

Fuel system lean (Bank 1)

R l t d DTC

P0172

Fuel system rich (Bank 1)

Related DTCs

P0174

Fuel system lean (Bank 2)

P0175

Fuel system rich (Bank 2)

Main sensors/components

Front oxygen sensor

Required sensors/components

Related sensors/components

Engine coolant temperature sensor, Mass air flow

meter, Crankshaft position sensor

Frequency of operation

Continuous

Duration

10 sec.

MIL operation

2 driving cycles

Sequence of operation

None