Suzuki: Engine K6A-YH6. Manual - part 10

5-4

TESTS AND ADJUSTMENTS

5

IMPORTANT

The check and adjustment must be performed when

engine is cold.

Continue turning the crankshaft so that each

different cam lobe will point away from the shim face

successively. Measure each valve clearance at this

position. (All the valve clearances can be measured

during two complete turns of crankshaft.)

Valve clearance and adjustment may be done in pairs

(Example: #1 Intake valves, then #2 Intake valves,

and so on.)

The valve clearance measurement must be

performed with the timing chain installed in place.

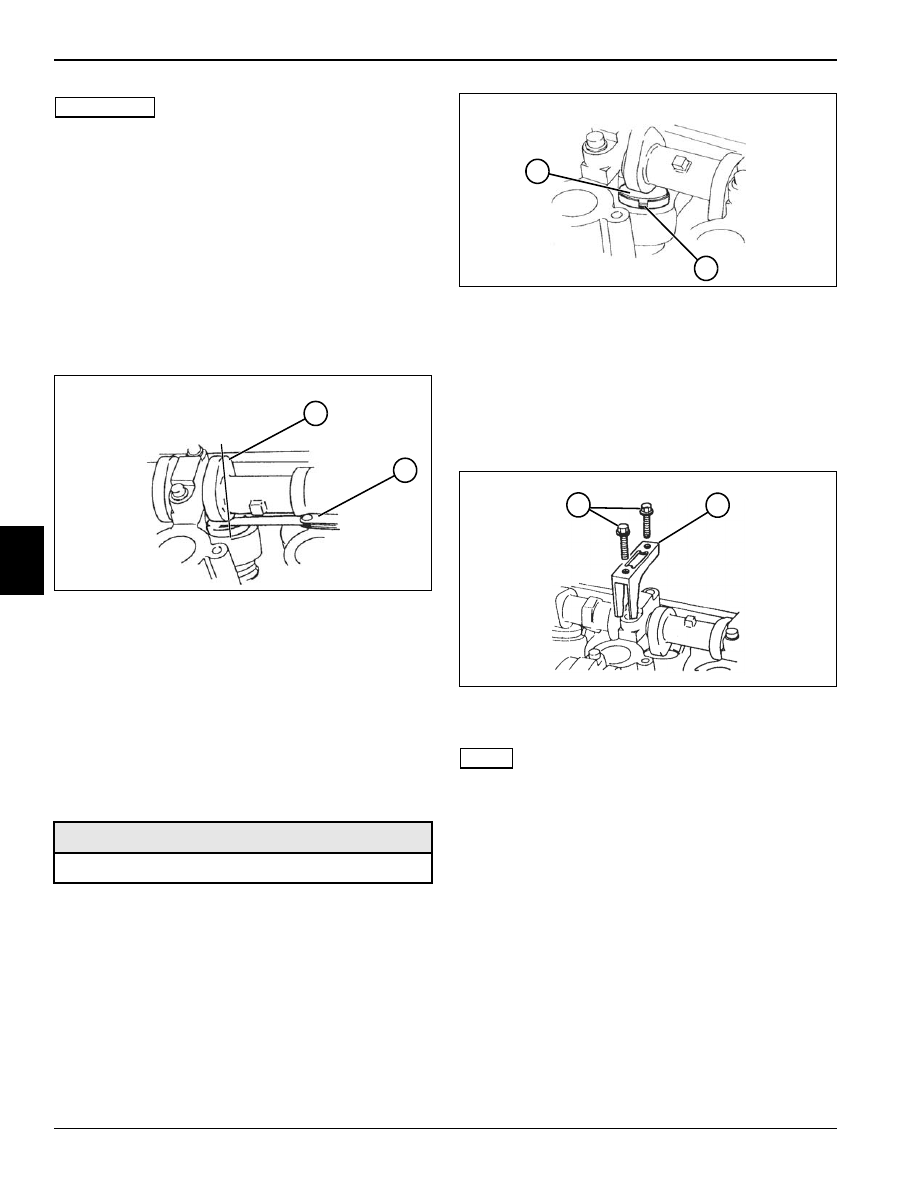

Figure 5-8

3.

When the cam lobe (2) to be checked points 180°

away from the shim face, measure the clearance

between the camshaft and shim using a feeler gauge

(3).

4.

Check measurement against valve clearance

specification.

5.

Perform adjustment procedure if valve clearance is

out of specification.

Adjustment

Figure 5-9

1.

If the valve clearance is out of specification, adjust it

by replacing the shim (1).

2.

Ensure that the valve is closed for the shim being

adjusted and turn the tappet to bring its cutaway (2)

inward.

3.

Turn the crankshaft to open the valve needing

adjustment.

Figure 5-10

4.

Remove the camshaft housing cap screws (3).

NOTE

The special tool stamped with “IN” must be used for

intake camshaft and tool with “EX” for exhaust camshaft.

Check that the special tool is not pushing on the shim.

5.

Attach the special tool (4) with the camshaft housing

cap screws. Torque to specification.

Tightening Torque: 97 lb-in. (11 N•m)

Required Tools

Tappet Holder: Jacobsen PN 4139726

TN0360

180

°

2

3

TN0361

2

1

TN0362

3

4