Suzuki: Engine K6A-YH6. Manual - part 8

THEORY OF OPERATION

4-9

4

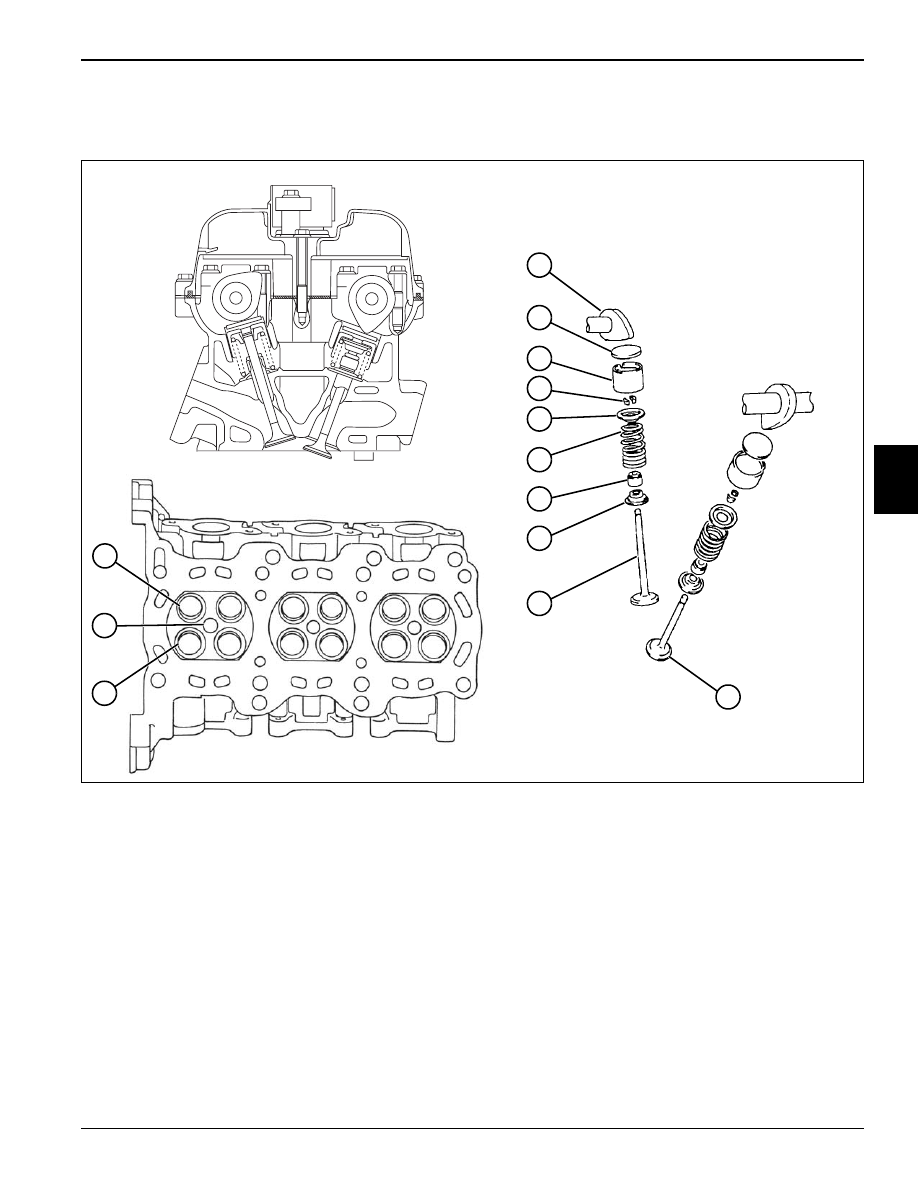

4.5 Cylinder Head and Valve Train

Figure 4-10

The twin cam, 4-valve per cylinder head is constructed

with an aluminum alloy that is both lightweight and

efficient in heat dissipation. Valve angle is set narrow to

also make for a compact head design.

The spark plug port (12) is located in the center of the

combustion chamber, with the combustion chamber

being a pent-roof design for improved combustion

efficiency.

The intake (11) and exhaust ports (13) are arranged in a

cross-flow style with each cylinder having two intake and

two exhaust valves for improved intake and exhaust

efficiency. Intake valves are faced with a dual angle while

exhaust valves have a single angle face.

The valve spring retainer (5), valve spring (6), valve seal

(7), and valve spring seat (8) are all installed over the

valve stem and held in place with the retainer locks (4).

The valves (9 and 10) are pushed down directly with the

camshaft lobe (1) via shim (2) and tappet (3). Valve lash

is adjusted by varying the thickness of the shim (2).

1

Camshaft Lobe

6

Valve Spring

11

Intake Port

2

Shim

7

Valve Seal

12

Spark Plug Port

3

Tappet

8

Valve Spring Seat

13

Exhaust Port

4

Retainer Lock

9

Intake Valve

5

Valve Spring Retainer

10

Exhaust Valve

TN0750, 0523, 0493

1

2

3

6

7

8

9

4

13

12

11

10

5