Subaru Legacy III (2000-2003 year). Manual - part 840

PS-48

POWER ASSISTED SYSTEM (POWER STEERING)

STEERING GEARBOX [LHD MODEL]

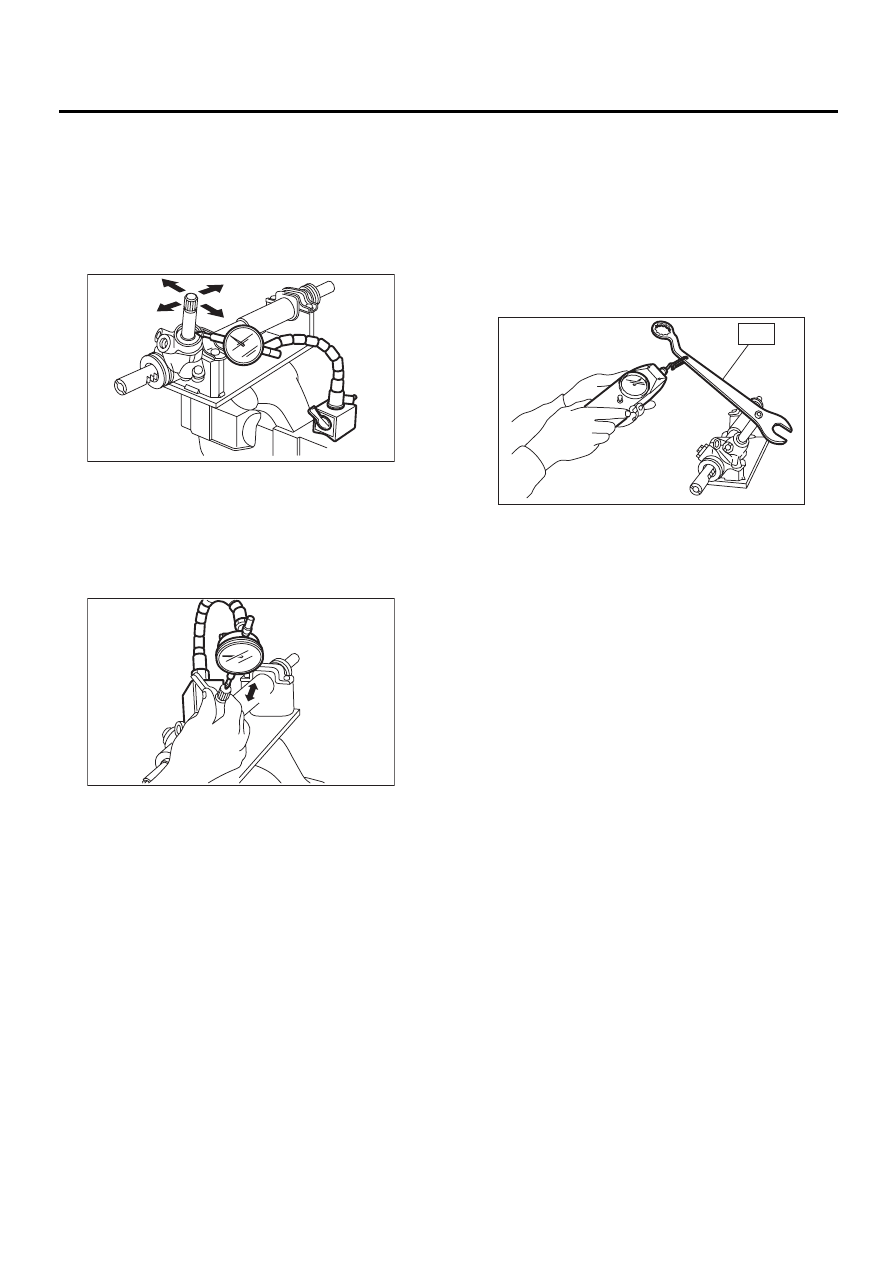

4. INPUT SHAFT PLAY

In radial direction:

Service limit

0.18 mm (0.0071 in) or less

On condition

P: 98 N (10 kgf, 22 lb)

In axial direction:

Service limit

0.5 mm (0.020 in) or less

On condition

P: 20 — 49 N (2 — 5 kgf, 4 — 11 lb)

5. TURNING RESISTANCE OF GEARBOX

Using ST, measure gearbox turning resistance.

ST

926230000

SPANNER

Service limit:

Straight-ahead position within 30 mm (1.18

in) from rack center

Less than 11.18 N (1.14 kgf, 2.51 lb)

Maximum allowable resistance

12.7 N (1.3 kgf, 2.9 lb)

PS-00103

P

PS-00104

P

PS-00105

ST