Subaru Legacy III (2000-2003 year). Manual - part 839

PS-44

POWER ASSISTED SYSTEM (POWER STEERING)

STEERING GEARBOX [LHD MODEL]

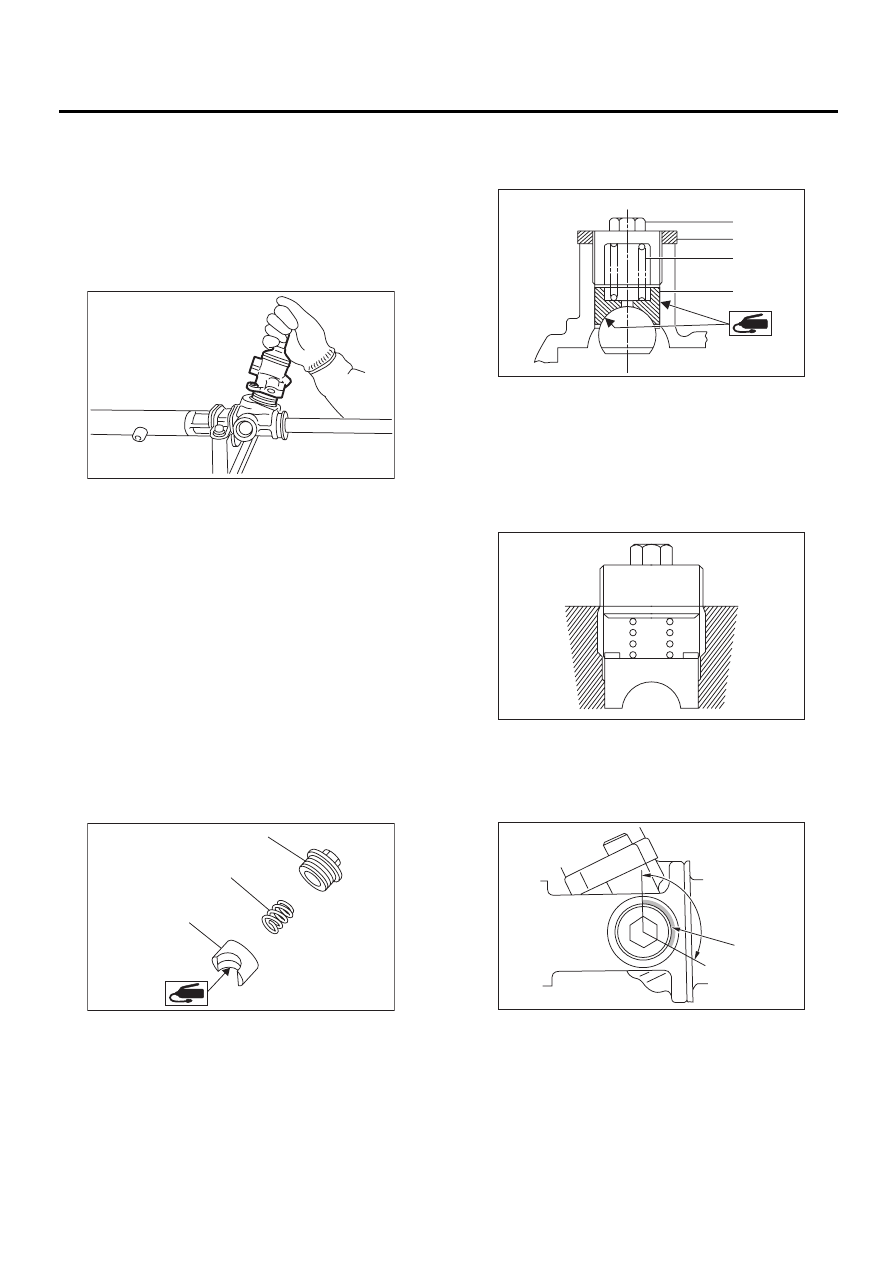

14) Install gasket on valve assembly. Insert valve

assembly into place while facing rack teeth toward

pinion.

CAUTION:

Be sure to use a new gasket.

NOTE:

Do not allow packing to be caught when installing

valve assembly.

15) Tighten bolts alternately to secure valve as-

sembly.

Tightening torque:

25 N·m (2.5 kgf-m, 18.1 ft-lb)

CAUTION:

Be sure to alternately tighten bolts.

16) Apply grease to sleeve insertion hole.

17) Apply grease to dust seal insertion hole.

CAUTION:

Apply clean grease with clean hands. If material

having a sharp edge is used for applying

grease, oil seal at the inside might be damaged.

18) Apply grease to sliding surface of sleeve and

spring seat, then insert sleeve into pinion housing.

Fit spring into sleeve screw, pack grease inside of

screw, then install the screw.

19) Rack and pinion backlash adjustment

(1) Loosen adjusting screw.

(2) Rotate input shaft so that rack is in the

straight ahead direction.

(3) Apply grease to sleeve.

(4) Tighten adjusting screw by approx. two

threads.

(5) Apply liquid packing to at least 1/3 of entire

perimeter of adjusting screw thread.

Liquid packing:

THREE BOND 1141

(6) Tighten adjusting screw to 7.4 N·m (0.75

kgf-m, 5.4 ft-lb) and back off 25

°

.

(1) Adjusting screw

(2) Spring

(3) Sleeve

PS-00117

PS-00211

( 1 )

( 2 )

( 3 )

(1) Adjusting screw

(2) Lock nut

(3) Spring

(4) Sleeve

(1) Apply liquid packing to at least 1/3 of entire

perimeter.

PS-00213

( 1 )

( 2 )

( 3 )

( 4 )

PS-00214

PS-00092

( 1 )