Subaru Legacy III (2000-2003 year). Manual - part 558

AT-126

AUTOMATIC TRANSMISSION

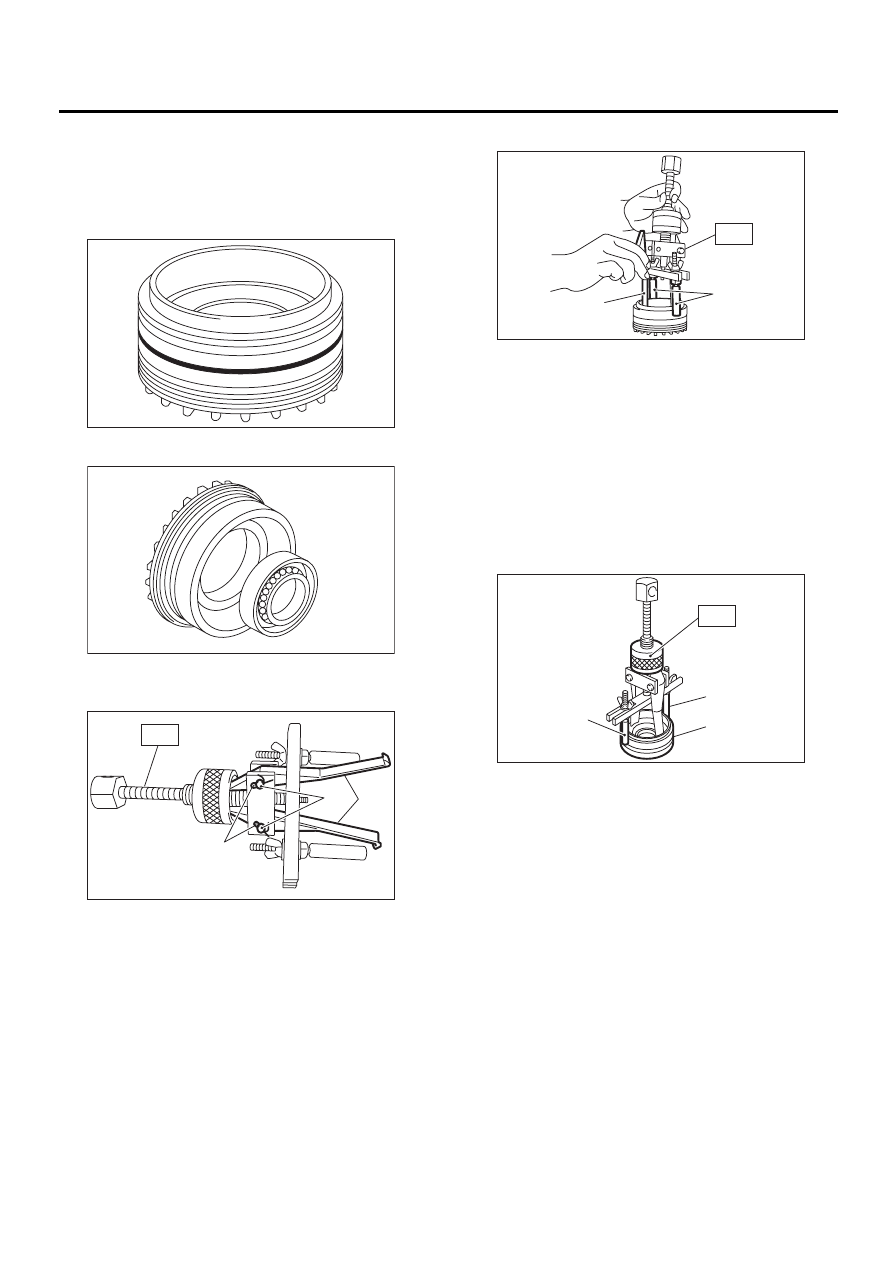

FRONT DIFFERENTIAL

2. SIDE RETAINER

NOTE:

After adjusting the drive pinion backlash and tooth

contact, remove and install the oil seal and O-ring.

1) Remove O-ring.

2) Remove oil seal.

3) Take out either split pin, remove claw.

ST

398527700

PULLER ASSY

4) Securely attach two claws to outer race, set ST

to side retainer.

ST

398527700

PULLER ASSY

5) Return removed claw to the original position,

and install pin and split pin.

6) Hold the shaft of ST to avoid removing from side

retainer, and then remove the bearing outer race.

ST

398527700

PULLER ASSY

NOTE:

Replace bearing inner and outer races as a single

unit.

(A) Claw

(B) Split pin

(C) Pin

AT-00219

AT-00220

AT-00221

ST

( A )

( B )

( C )

(A) Shaft

(B) Claw

(A) Shaft

(B) Side retainer

AT-00222

( A )

( B )

ST

AT-00223

ST

( B )

( A )