Subaru Legacy III (2000-2003 year). Manual - part 456

SC(H4DOSTC)-12

STARTING/CHARGING SYSTEMS

STARTER

7. PINION GAP

1) Measure the pinion gap while the pinion is pulled

out as shown in the figure.

Pinion gap:

0.5 — 2.0 mm (0.020 — 0.079 in)

If the motor is running with the pinion forced end-

wise on shaft, disconnect the connector from termi-

nal M of switch assembly, and then connect termi-

nal M to ground terminal (

−

) of battery with a lead

wire. Next, gently push the pinion back with your

fingertips, and then measure the pinion gap.

2) If the pinion gap is outside specified range, re-

move or add number of adjustment washers used

on the mounting surface of switch assembly until

correct pinion gap is obtained.

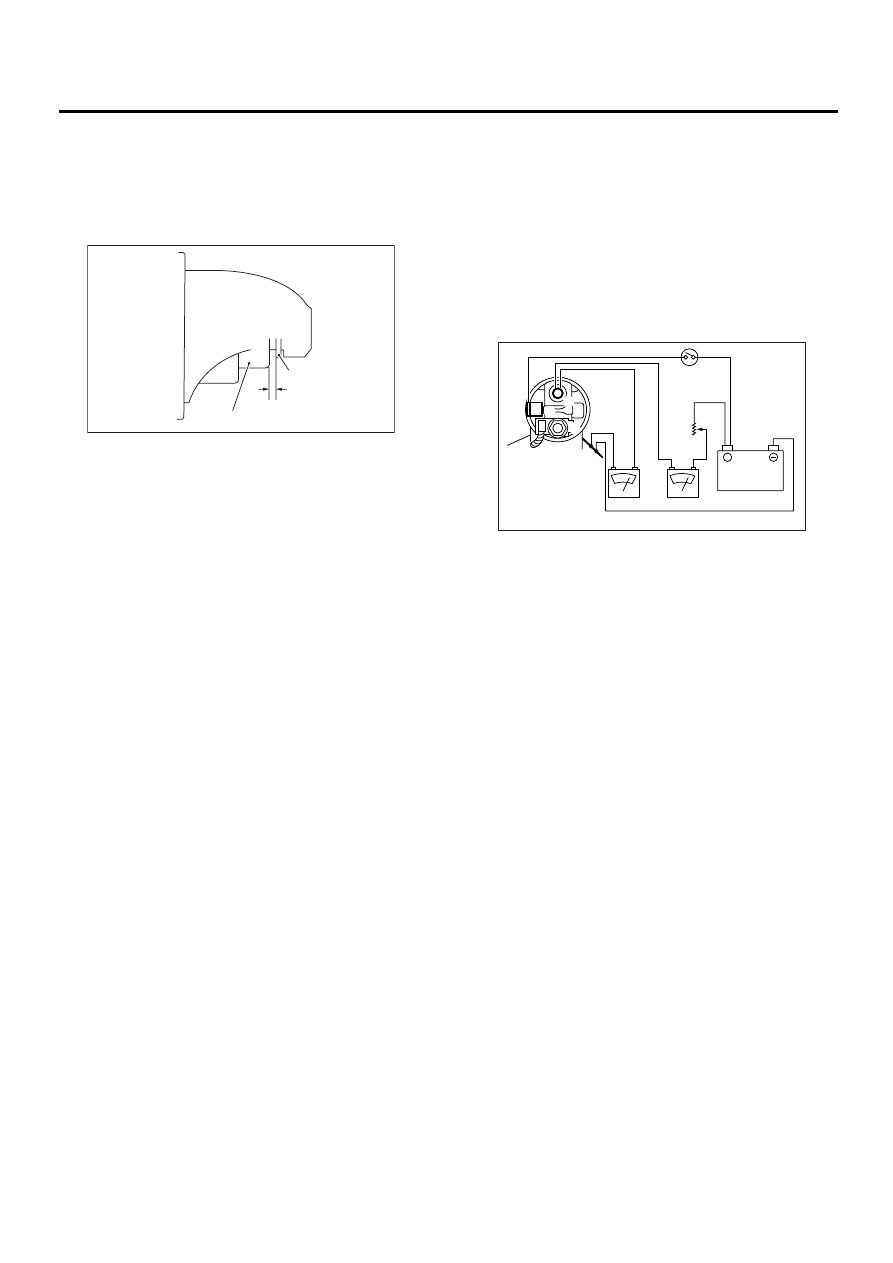

8. PERFORMANCE TEST

The starter should be submitted to performance

tests whenever it has been overhauled, to assure

its satisfactory performance when installed on the

engine.

Three performance tests, no-load test, load test,

and lock test, are presented here; however, if the

load test and lock test cannot be performed, carry

out at least the no-load test.

For these performance tests, use the circuit shown

in figure.

1) No-load test

With switch on, adjust the variable resistance to ob-

tain 11 V, take the ammeter reading, and then mea-

sure the starter speed. Compare these values with

the specifications.

No-load test (Standard):

Voltage / Current

MAX. 11 V / 90 A

Rotating speed

MT vehicles

2,800 rpm or more

AT vehicles

2,400 rpm or more

(A) Pinion

(B) Gap

(C) Stopper

SC-00027

( A )

( B )

( C )

(A) Variable resistance

(B) Magnetic switch

(C) Starter body

SC-00077

(A)

(B)

(C)

12V

+

A

V

B

S

M