Subaru Legacy III (2000-2003 year). Manual - part 430

ME(H4DOSTC)-84

MECHANICAL

CYLINDER BLOCK

Standard diameter:

A: 92.005 — 92.015 mm (3.6222 — 3.6226

in)

B: 91.995 — 92.005 mm (3.6218 — 3.6222

in)

2) How to measure the inner diameter of each cyl-

inder:

Measure the inner diameter of each cylinder in both

the thrust and piston pin directions at the heights

shown in the figure, using a cylinder bore gauge.

NOTE:

Measurement should be performed at a tempera-

ture of 20

°

C (68

°

F).

Taper:

Standard

0.015 mm (0.0006 in)

Limit

0.050 mm (0.0020 in)

Out-of-roundness:

Standard

0.010 mm (0.0004 in)

Limit

0.050 mm (0.0020 in)

3) When the piston is to be replaced due to general

or cylinder wear, determine a suitable sized piston

by measuring the piston clearance.

4) How to measure the outer diameter of each pis-

ton:

Measure the outer diameter of each piston at the

height shown in the figure. (Thrust direction)

NOTE:

Measurement should be performed at a tempera-

ture of 20

°

C (68

°

F).

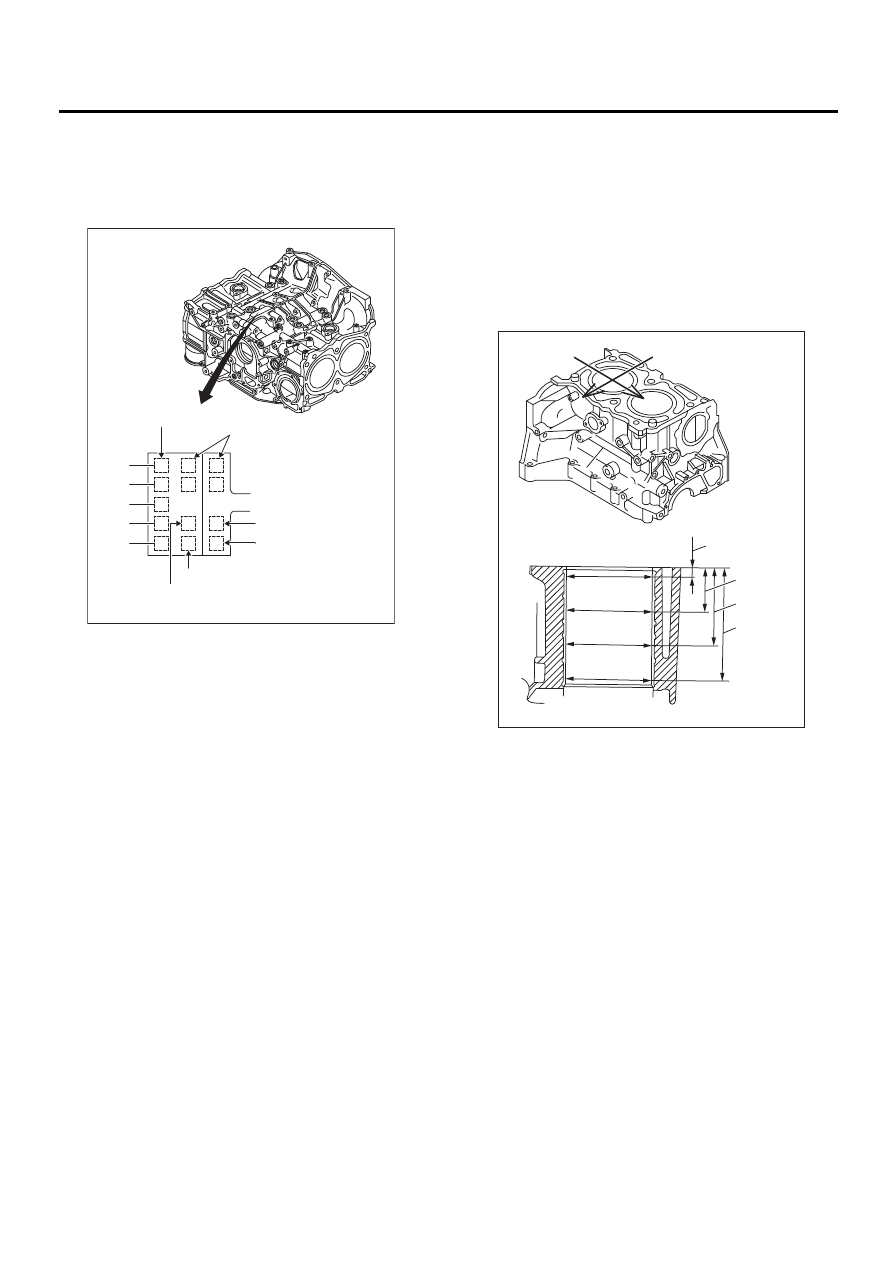

(A) Main journal size mark

(B) Cylinder block RH-LH combination mark

(C) #1 cylinder bore size mark

(D) #2 cylinder bore size mark

(E) #3 cylinder bore size mark

(F) #4 cylinder bore size mark

ME-00170

#4

#5

#3

#2

#1

5

4

5

4

A

B

A

B

( B )

( C )

( D )

( E )

( F )

( A )

(A) Piston pin direction

(B) Thrust direction

H1: 10 mm (0.39 in)

H2: 45 mm (1.77 in)

H3: 80 mm (3.15 in)

H4: 115 mm (4.53 in)

ME-00171

H1

H2

H3

H4

( A )

( B )