Subaru Legacy III (2000-2003 year). Manual - part 59

ME(H4SO)-48

MECHANICAL

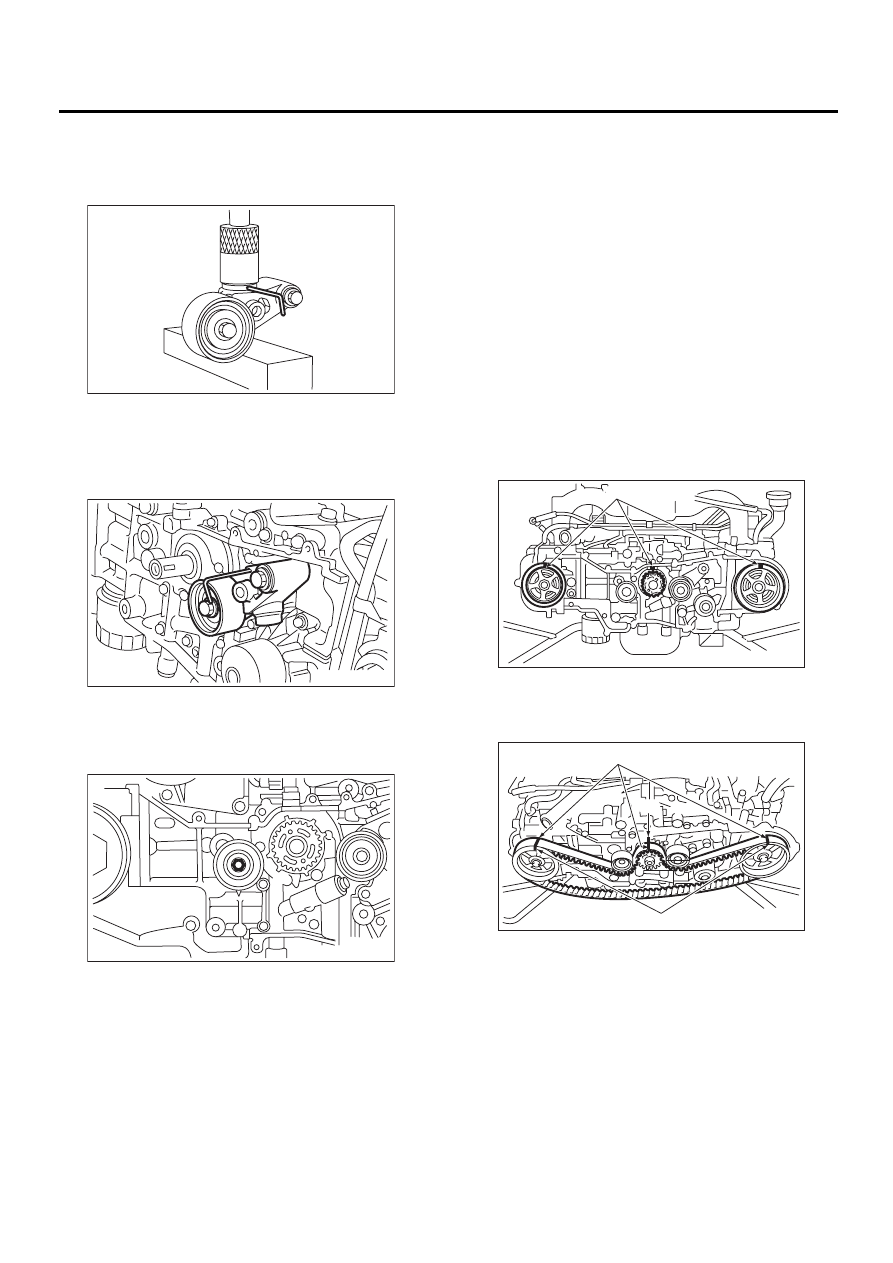

TIMING BELT ASSEMBLY

(3) With a 2 mm (0.08 in) dia. stopper pin or a 2

mm (0.08 in) (nominal) dia. hex bar wrench in-

serted into the stopper pin hole in the cylinder,

secure the adjuster rod.

2) Install the automatic belt tension adjuster as-

sembly.

Tightening torque:

39 N·m (4.0 kgf-m, 28.9 ft-lb)

3) Install the belt idler (No. 1).

Tightening torque:

39 N·m (4.0 kgf-m, 28.9 ft-lb)

2. TIMING BELT

1) Preparation for the installation of automatic belt

tension adjuster assembly. <Ref. to ME(H4SO)-47,

AUTOMATIC BELT TENSION ADJUSTER AS-

SEMBLY AND BELT IDLER, INSTALLATION,

Timing Belt Assembly.>

2) Installation of timing belt

(1) Turn the camshaft sprocket No. 2 using

ST1, and then turn the camshaft sprocket No. 1

using ST2 so that their alignment marks (A)

come to top positions.

ST1

18231AA010 CAMSHAFT SPROCKET

WRENCH

NOTE:

Also the CAMSHAFT SPROCKET WRENCH

(499207100) can be used.

ST2

499207400

CAMSHAFT SPROCKET

WRENCH

(2) While aligning alignment marks (B) on the

timing belt with marks (A) on sprockets, position

the timing belt properly.

3) Install the belt idler No. 2.

Tightening torque:

39 N·m (4.0 kgf-m, 28.9 ft-lb)

ME-00437

ME-00241

ME-00242

( A )

ME-00243

ME-00244

( A )

( A )

( B )