Subaru Impreza 3 / Impreza WRX / Impreza WRX STI. Manual - part 157

ME(w/o STI)-9

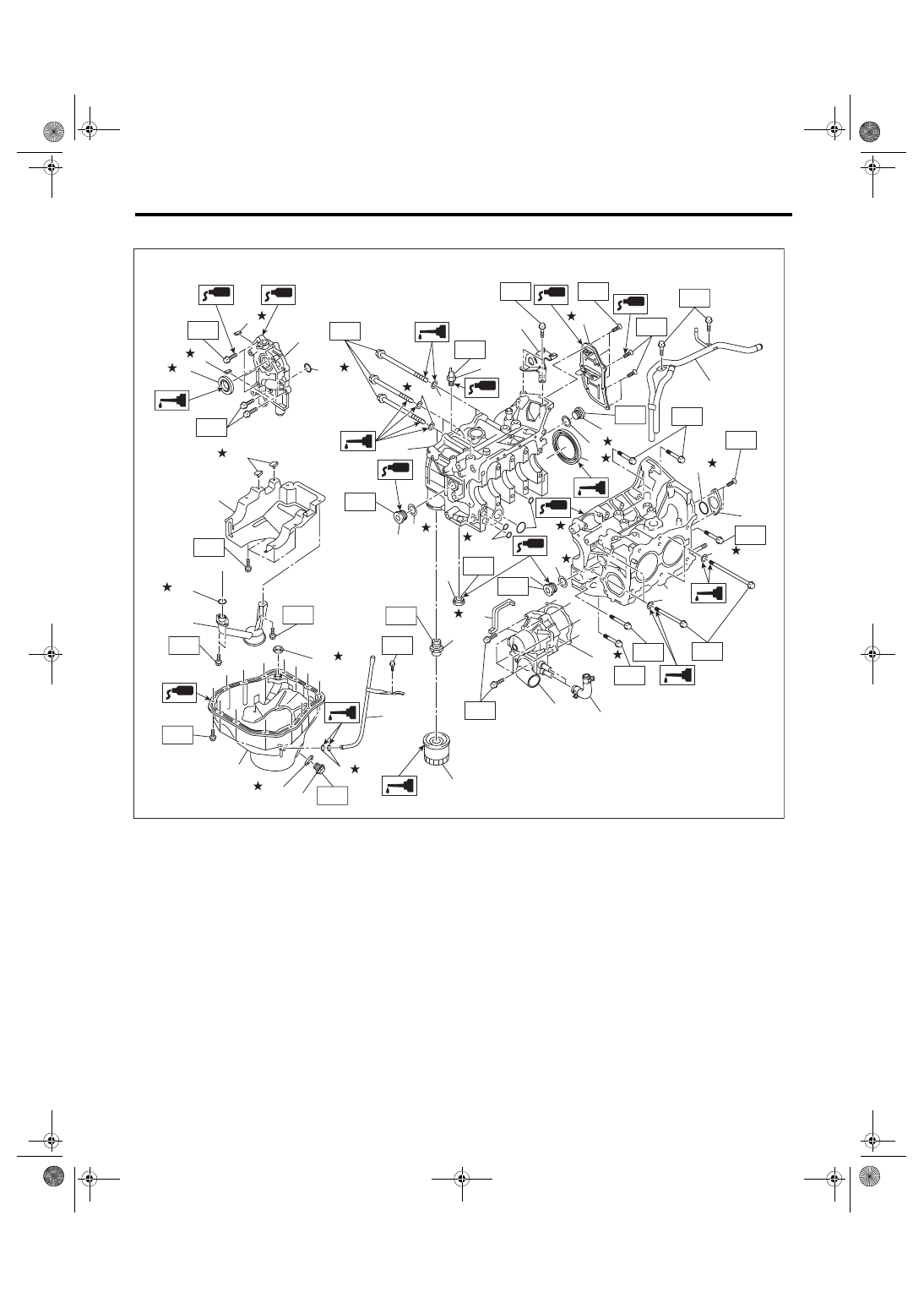

General Description

MECHANICAL

4. CYLINDER BLOCK

ME-05000

T4

T2

T2

T10

T6

T10

T6

T2

T9

T9

(9)

(10)

(10)

(11)

(13)

(25)

(26)

(4)

(4)

(4)

(3)

(3)

(3)

(2)

(5)

(10)

T6

(24)

(17)

(27)

T9

T2

(14)

(28)

T3

(18)

(10)

T2

(29)

(31)

T1

T7

(19)

(20)

(21)

(22)

(30)

(29)

(30)

(12)

(16)

T8

T2

(6)

T2

(10)

T2

(8)

(7)

(15)

(15)

T2

T2

(23)

T9

T6

(1)

T5

(32)