Subaru Impreza 3 / Impreza WRX / Impreza WRX STI. Manual - part 107

LU(STI)-30

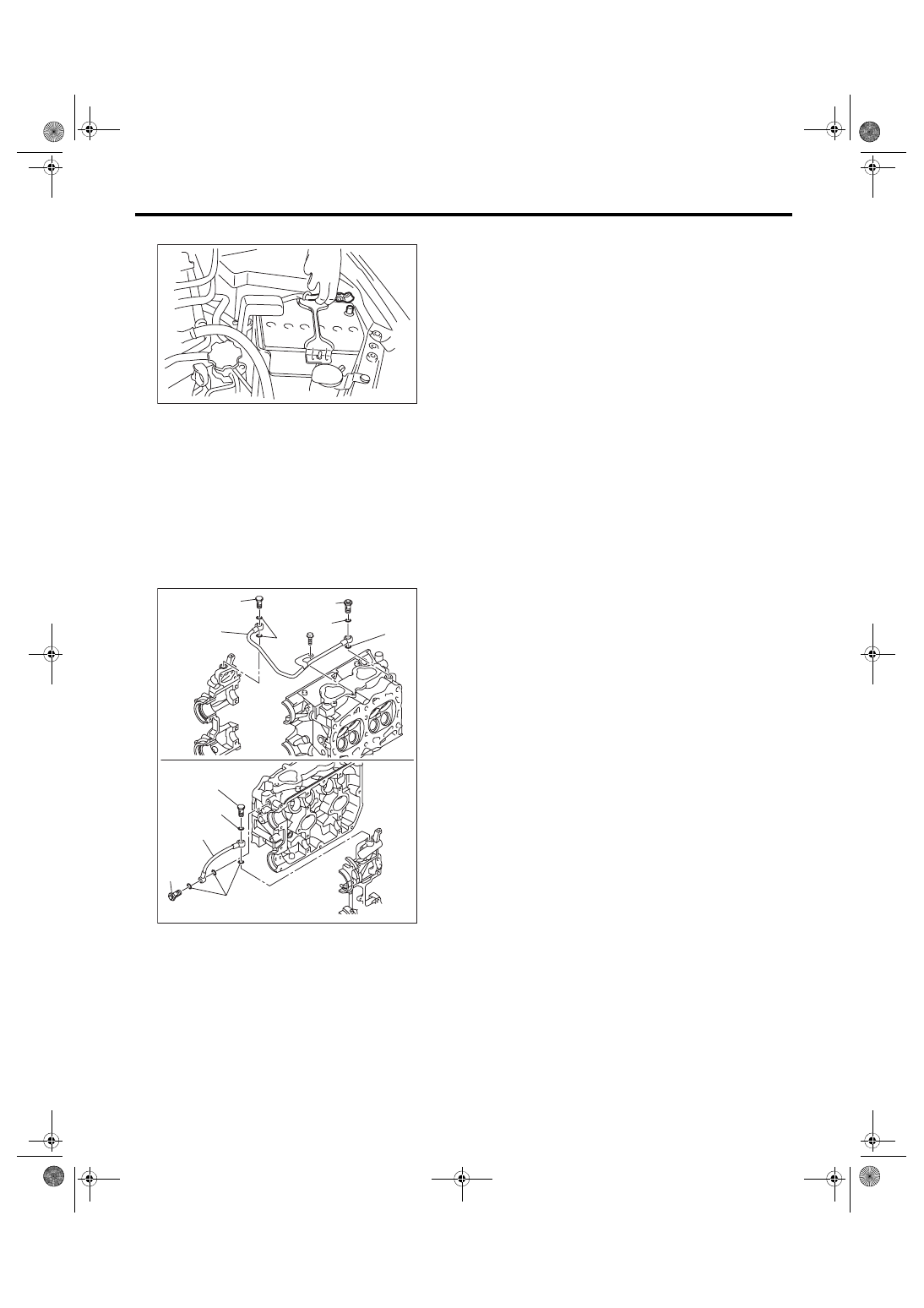

Oil Pipe

LUBRICATION

19) Connect the battery ground terminal.

20) Fill engine coolant. <Ref. to CO(STI)-13, FILL-

ING OF ENGINE COOLANT, REPLACEMENT,

Engine Coolant.> <Ref. to CO(w/o STI)-13, FILL-

ING OF ENGINE COOLANT, REPLACEMENT,

C: INSPECTION

1. INSPECTING UNION BOLT WITH FILTER

Check the filter part of union bolt for clogging or

damage, and if defective, replace the union bolt

with filter with the new part.

2. OTHER INSPECTIONS

1) Check that the oil pipe and union bolt have no

deformation, cracks and other damages.

2) Check that there are no oil leaks or oil oozing

from the oil pipe attachment section.

(A) Union bolt with filter (with protrusion)

(B) Union bolt without filter (without protrusion)

(C) Oil pipe RH

(D) Oil pipe LH

(E) Gasket

IN-00203

ME-05030

(A)

(B)

(D)

(A)

(B)

(C)

(E)

(E)

(E)

(E)

(E)