Subaru Legacy (2005 year). Manual - part 713

FS-23

FRONT SUSPENSION

Front Strut

7) Pull the piston rod fully upward, and install the

spring seat.

NOTE:

Ensure the upper spring seat is positioned as

shown in the figure.

8) Install the strut mount to piston rod, and tempo-

rarily tighten a new self-locking nut.

9) Using a hexagon wrench to prevent strut rod

from turning, tighten the new self-locking nut with

ST.

ST

20399AG000 STRUT MOUNT SOCKET

Tightening torque:

70 N

⋅

m (7.1 kgf-m, 51.6 ft-lb)

10) Loosen the coil spring carefully.

E: INSPECTION

Check the removed part for wear, damage and

cracks, and then repair or replace it if defective.

1. DAMPER STRUT

1) Check for oil leaks.

2) Move the piston rod up and down to check that it

operates smoothly without any hitch.

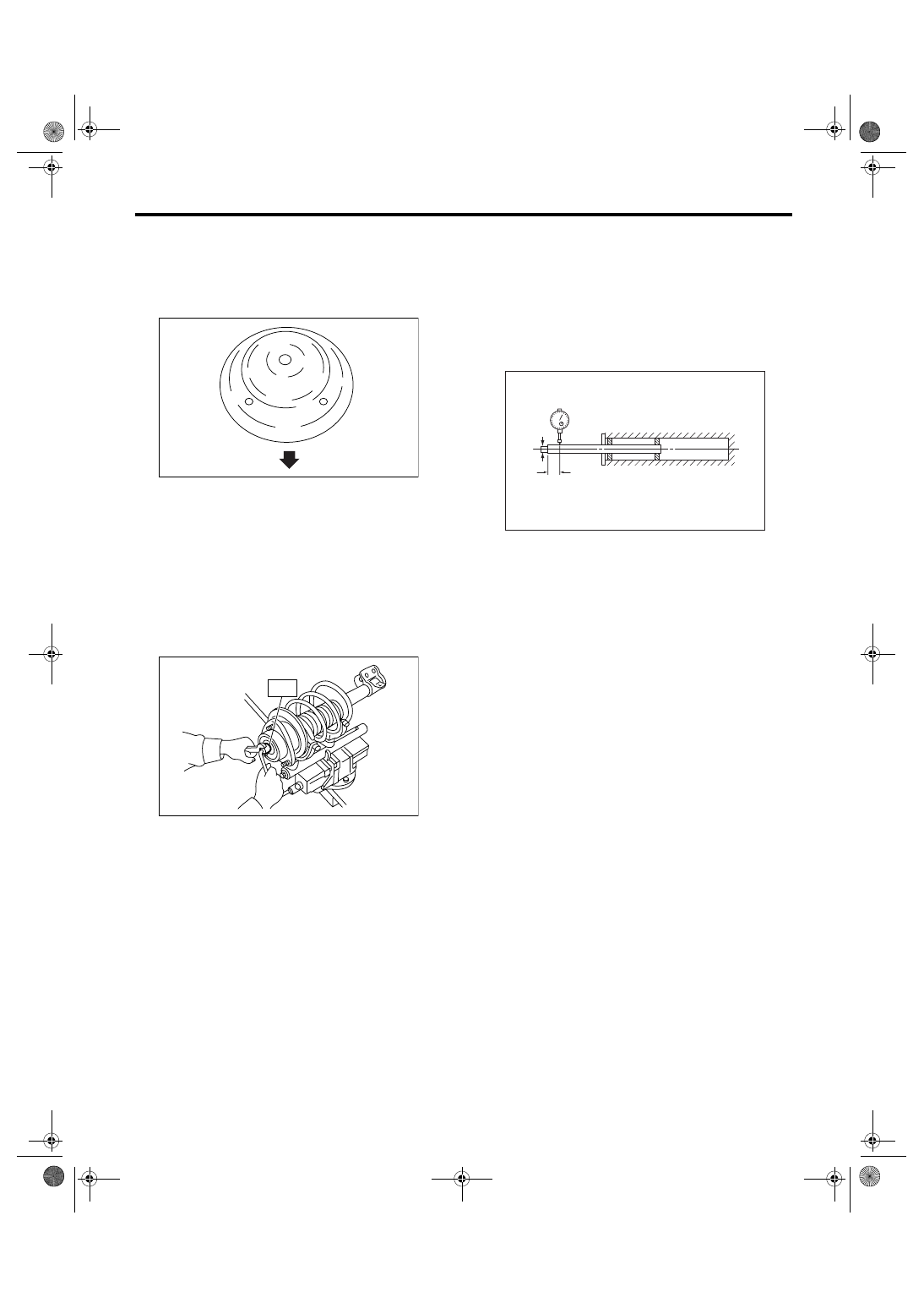

3) Piston rod play

• Measure the play as follows:

Fix the outer shell and fully extend the rod. Set a

dial gauge at the end of rod L [10 mm (0.39 in)], and

then read the dial gauge indication P

1

while apply-

ing a force of W [20 N (2 kgf, 4 lbf)] to threaded end.

Apply a force of 20 N (2 kgf, 4 lbf) in the opposite di-

rection of “W”, and then read the dial gauge indica-

tion P

2

.

Play limit (P

1

+ P

2

):

0.8 mm (0.031 in)

If the play exceeds limit, replace the strut.

2. STRUT MOUNT

Check the rubber part for deformation, cracks or

deterioration, and then replace it with a new one if

defective.

3. DUST COVER

If any cracks or damage are found, replace it with a

new one.

4. COIL SPRING

If a permanent strain is found, replaced it with a

new one.

5. HELPER

Replace it with a new one if cracked or damaged.

F: DISPOSAL

1. EXCEPT BILSTEIN STRUT

CAUTION:

• Before handling struts, be sure to wear gog-

gles to protect eyes from gas, oil and cutting

powder.

• Do not disassemble the strut damper or place

into a fire.

• Drill a hole into struts in case of discarding

struts filled with gas.

1) Place the strut on a level surface with the piston

rod fully expanded.

(1) Outside of body

FS-00128

(1)

FS-00041

ST

FS-00046

W

L