Subaru Legacy (2005 year). Manual - part 688

6MT-99

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

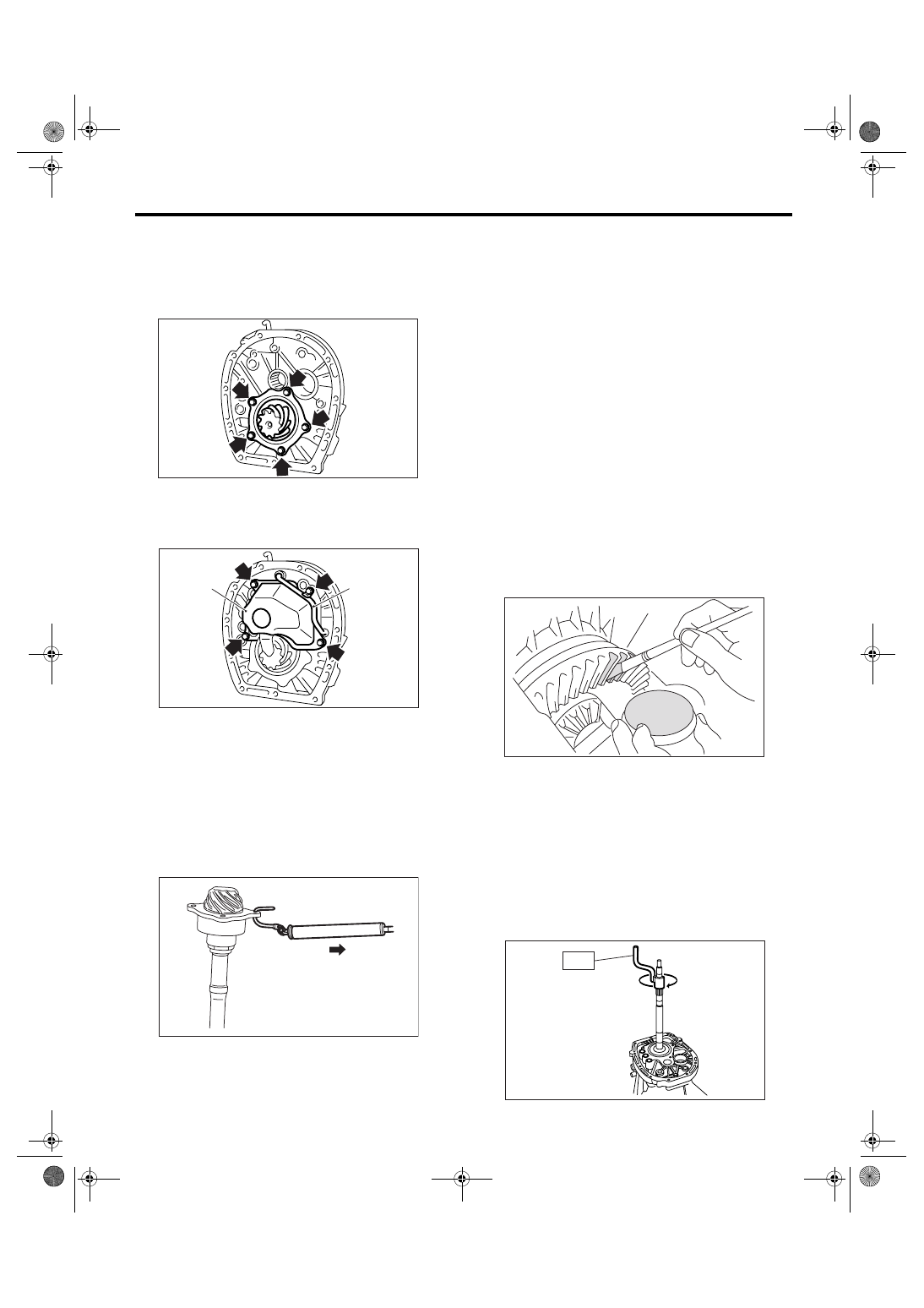

10) Apply gear oil to the side face of taper roller

bearing, then install the drive pinion shaft and se-

lected shim to adapter plate.

Tightening torque:

54 N

⋅

m (5.5 kgf-m, 40 ft-lb)

11) Install the oil chamber and pipe.

Tightening torque:

6.4 N

⋅

m (0.65 kgf-m, 4.7 ft-lb)

E: INSPECTION

1) Using the spring balance, measure the starting

torque. If the starting torque is out of specification,

replace the taper roller bearing.

Starting torque:

0 — 0.95 N (0 — 0.097 kgf, 0 — 0.21 lbf)

2) Gear

Replace the gear in the following cases.

• When the gear teeth surfaces are broken or ex-

cessively worn.

3) Bearing

Replace the bearings in the following cases.

• When there are wear, rust and damage on the

bearing.

• When bearing that fails to turn smoothly or

makes noise when turned.

4) Adapter plate

Replace the adapter plate in the following cases.

• When the bearing is worn, rusted and damaged.

• When there is damage on adapter plate.

5) Make sure the pipe and pipe chamber is not

damaged or clogged. Repair or replace if damaged

or clogged.

F: ADJUSTMENT

1) Inspect and adjust the backlash between hypoid

driven gear and drive pinion. <Ref. to 6MT-108,

HYPOID GEAR BACKLASH, ADJUSTMENT,

Front Differential Assembly.>

2) Apply a uniform thin coat of red lead on both

tooth surfaces of three or four teeth of the hypoid

driven gear.

3) Install the drive pinion shaft assembly to clutch

housing, then tighten at least four bolts.

NOTE:

Install with the liquid gasket remaining to prevent

the mating surface of clutch housing and adapter

plate from damaging.

Tightening torque:

50 N

⋅

m (5.1 kgf-m, 36.9 ft-lb)

4) Using the ST, rotate several times.

ST

18631AA000

HANDLE

(A) Pipe

(B) Oil chamber

MT-00642

(A)

(B)

MT-00641

MT-00651

MT-00652

MT-00653

ST