Subaru Legacy (2005 year). Manual - part 687

6MT-95

MANUAL TRANSMISSION AND DIFFERENTIAL

Reverse Idler Gear

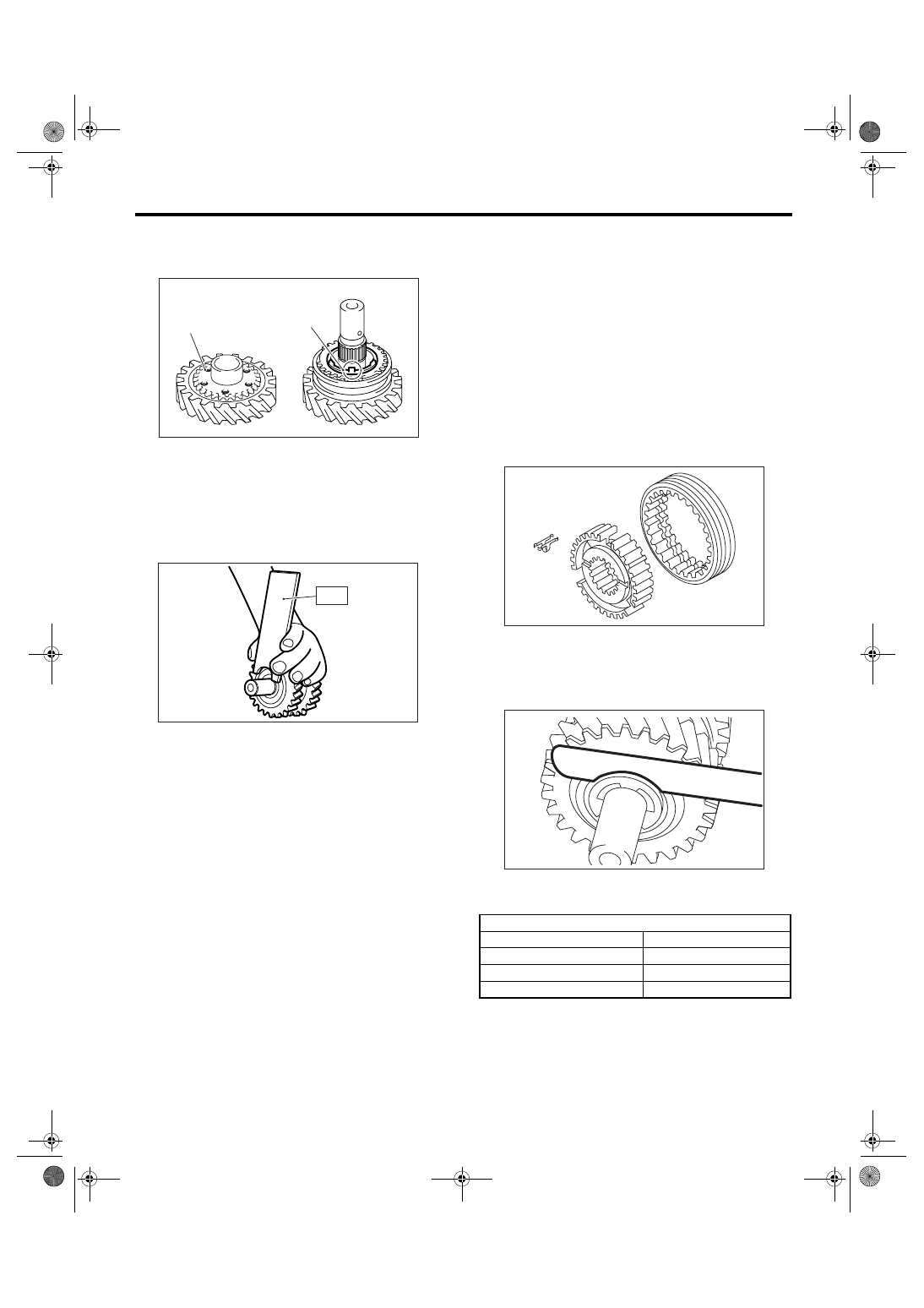

12) Align the protrusion portion of reverse synchro

cone with reverse idler gear hole, then install the

reverse idler gear.

13) Install the washer with groove facing to reverse

idler gear.

14) Using the ST, install the snap ring.

ST

18672AA000

GUIDE CLIP

15) Inspect and adjust the clearance between snap

ring and washer. <Ref. to 6MT-95, INSPECTION,

Reverse Idler Gear.>

16) Install the spring pin.

NOTE:

Use a new spring pin.

E: INSPECTION

Disassembled parts should be washed with un-

leaded gasoline first and then inspected carefully.

1) Bearing

Replace the bearings in the following cases.

• When there are wear, rust and damage on the

bearing.

• When bearing that fails to turn smoothly or

makes noise when turned.

• When bearings have other defects.

2) Bushing (each gear)

Replace the bushing in following cases.

• When the sliding surface is damaged or abnor-

mally worn.

3) Gear

Replace the gear in the following cases.

• When the gear teeth surfaces are broken or ex-

cessively worn.

• When the parts that contact the baulk ring is

damaged.

• When the inner surface of gear is damaged.

4) Baulk ring, synchro cone

Replace the baulk ring and synchro cone in the fol-

lowing case.

• When there are wear, rust and damage on the

baulk ring.

5) Shifting insert key

Replace the shifting insert key if deformed, exces-

sively worn or defective in any way.

6) Inspect the clearance between snap ring and

washer.

Tip clearance specification:

0.1 — 0.3 mm (0.0039 — 0.0118 in)

Select the snap ring from the following table if

clearance is out of specification.

Inspect the clearance again after replacing snap

ring.

(A) Protrusion portion of reverse synchro cone

(B) Reverse idler gear hole

(A)

(B)

MT-00637

MT-00638

ST

Snap ring

Part No.

Thickness mm (in)

031319000

1.50 (0.059)

805019030

1.60 (0.062)

805019010

1.72 (0.068)

MT-00581

MT-00639